Before undergoing deep processing (such as cocoa paste and cocoa powder), cocoa beans must first undergo efficient and precise cleaning and screening processes to ensure raw material purity and subsequent product quality.

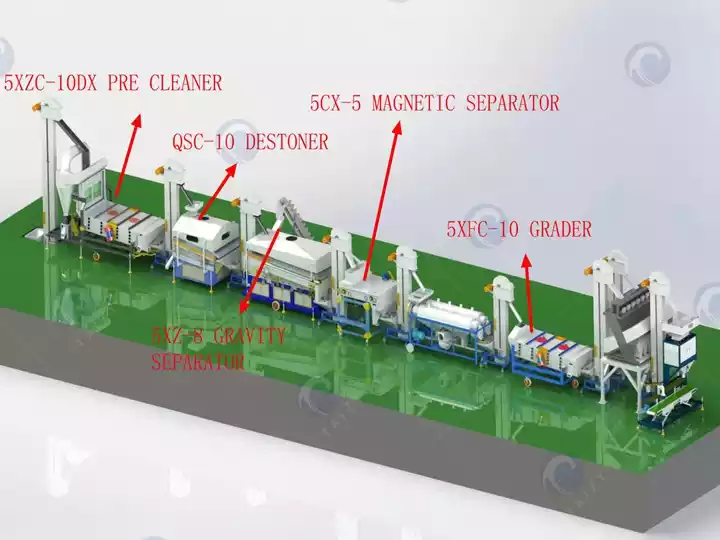

Our cocoa bean cleaning line consists of a pre-cleaner, destoner, gravity separator, magnetic separator, and grader. It achieves a cleaning rate exceeding 99.8% and a stone removal rate surpassing 99.5%, effectively eliminating dust, stones, metallic impurities, defective beans, and insect-damaged particles.

The entire line features a rational structure and high automation, making it suitable for large-scale continuous production. It significantly reduces raw material loss, providing cocoa processing enterprises with a high-standard, high-value-added pre-processing solution.

Seed pre-cleaning machine

The 5XZC series pre-cleaning machine is widely used for cleaning and grading grains, seeds, and agricultural byproducts such as corn, wheat, rice, peanuts, soybeans, millet, sunflower seeds, melon seeds, grass seeds, spices, cocoa beans, pepper, and cumin.

This equipment efficiently removes light impurities and foreign matter of various sizes while performing screening and grading of materials, making it an indispensable core component in grain processing and seed treatment operations.

Main structure

The seed cleaner machine consists of a machine frame,elevator system,seeds distributed box,air screen, vibration sieve, dust collector, seed discharged outlet, and control cabinet.

Working principle

Raw materials enter through the feed hopper and are conveyed by the bucket elevator to the distribution box, where they are evenly distributed before entering the airflow screen.

- Airflow separation: within the airflow screen, lightweight impurities (dust, straw, chaff, etc.) are drawn away by the blower and discharged from the cyclone separator.

- Screening separation: the remaining material enters the vibrating screen box. Under the action of screens with different mesh sizes, large impurities, small impurities, and qualified seeds are discharged from their respective outlets.

By replacing screens of different specifications, the equipment can process various types of seeds and agricultural products, demonstrating strong adaptability.

Performance features

- High-capacity design suitable for mass production.

- Zero-breakage bucket elevator preserves material integrity.

- Adjustable airflow adapts to varying material properties.

- Enclosed air duct ensures environmental compliance and low dust emissions.

- High-efficiency vibrating screen with rubber ball cleaning mechanism to prevent screen clogging.

- Fully mobile unit equipped with tires for easy repositioning.

- Simple operation, convenient maintenance, robust construction, and stable operation.

- Automatic cleaning system: self-cleaning air chamber, screen layer, and discharge port ensure continuous operation.

Technical parameters

| Model | Capacity (t/h) | Power (kw) | Weight (kg) | Size (L×W×H, mm) | Screen Dimension (L×W×Layer, mm) | Cleaning Rate | Voltage |

| 5XZC-5DX | 5 | 8.1 | 1750 | 4300×1800×3200 | 2000×1000×4 | ≥98.5% | 380V (220V/440V customizable), 50/60Hz, 3 phase |

| 5XZC-10DX | 10 (based on process wheat) | Total: 10.5 Bucket elevator: 0.75 Air fan: 7.5 Dust collector: 0.75 Vibration motor: 0.75×2 | 2100 | 4800×2500×3600 | 2400×1500×4 | ≥98.5% | 380V (220V/440V customizable), 50/60Hz, 3 phase |

| 5XZC-20DX | 15 | 10.85 | 2300 | 4800×2700×3200 | 2400×1800×3 | ≥98.5% | 380V (220V/440V customizable), 50/60Hz, 3 phase |

Destoner machine

The QSC-10 Stone Remover effectively removes stones and soil impurities similar in size to the raw material. It is widely used in processing lines for various grains and cash crops, including sesame seeds, beans, quinoa, corn, coffee beans, wheat, peanuts, and more.

Machine advantages

- Achieves removal rates exceeding 99.5%, ensuring high purity of finished products.

- Equipped with a high-precision multi-blade fan delivering uniform and adjustable airflow.

- Stainless steel mesh surface ensures long-term stable operation with excellent wear and corrosion resistance.

- Flexible adjustment of pressure and vibration frequency accommodates varying raw material characteristics for strong adaptability.

- Features a variable frequency drive enabling precise fine-tuning, enabling efficient separation even for stones with minimal density differences.

Working principle

The destoner machine utilizes the density difference between grains and stones for separation. After raw materials enter the equipment:

- Airflow action: a high-precision multi-blade fan lifts lighter grains into suspension.

- Screen adhesion: heavier stones adhere tightly to the stainless steel screen.

- Vibration separation: by adjusting the vibration frequency of the workbench, stones and grains are thoroughly separated.

- Precision control: even when the density difference between stones and grains is minimal, variable frequency adjustment ensures highly efficient separation.

Technical data

| Model | QSC-10 |

| Size L×W×H | 2550*2000*1600 mm |

| Weight | 950 kg |

| Capacity | 10 T/H(Based on process wheat) |

| Cleaning rate | ≥99.5% |

| Voltage | 380V(220V/440V need customized) 50/60hz 3 phase |

| Screen dimension | 2000*1800 mm |

| Power | Total:7.35 kw Bucket elevator motor:0.75kw Air fan motor: 5.5kw Vibration motor:1.1 |

Gravity separator

The 5XZ-8 Gravity Positive Pressure Specific Gravity Classifier is suitable for grading and purifying various granular materials such as grain seeds, coarse grains and pulses, melon seeds, and nuts.

This machine effectively removes inferior seeds (e.g., moldy, insect-damaged, black powdery mildew-infected, or shelled grains) and sand/stone impurities. Cleaning effect of purity,germination rate, weight of per 1000 seeds are very outstanding.

Machine features

- Achieves a cleaning rate exceeding 99.8% with high screening precision.

- Features a built-in control cabinet for space-saving and aesthetically pleasing design.

- The gravity screen features an aluminum alloy frame and food-grade stainless steel mesh surface for durability and hygiene.

- Screens can be quickly replaced to accommodate different material sizes.

- Side conveyor belt design enhances production efficiency.

- Equipped with shock absorption devices for smooth operation and low failure rates.

- Vibration is controlled by variable frequency, allowing flexible adjustment for different seed types.

- Bottom casters enable standalone mobile operation or fixed installation for continuous production line use.

- Equipped with seven independent air chambers. Airflow is adjustable via handles, and each chamber features a pressure gauge for intuitive and precise calibration.

Working process

This machine achieves density separation of materials through the combined effects of airflow and vibrational friction:

- Raw materials are conveyed by an elevator into the gravity screen, where they are evenly distributed under vibration.

- Heavier materials (such as healthy, plump seeds) settle to the bottom layer and move upward due to friction on the screen surface.

- Lighter materials (e.g., insect-damaged, moldy, or shelled grains) are suspended by airflow at the surface layer and flow out along the lower section.

- Impurities (e.g., stones, sand particles) and inferior seeds are thoroughly separated, while qualified seeds are collected through a dedicated outlet.

Through this process, the gravity positive pressure density separator achieves efficient seed-impurity separation in a single operation. This ensures product quality, meeting the demands of large-scale production and high-standard seed processing.

Machine parameters

| Model | 5XZ-8 |

| Size L×W×H | 4100*2960*2935 mm |

| Weight | 1700 KG |

| Capacity | 8 T/H(Based on process wheat) |

| Cleaning rate | ≥99.8.% |

| Voltage | 380V(220V/440V need customized) 50/60hz 3 phase |

| Screen dimension | 3300*1500 mm |

| Power | Total:14.32kw Bucket elevator motor:0.75kw Air fan motor: 11kw Side conveyor belt:0.37kw Vibration motor:2.2 |

Magnetic separator

The 5CX-5 magnetic separator is widely applicable in processing lines for various agricultural products such as soybeans, peanuts, rice, and coarse grains. It effectively removes metallic impurities, magnetic soil clumps, and magnetic mud mixed in the raw materials, ensuring the purity and safety of the finished products.

Machine characteristics

- Magnetic roller magnetic field strength reaches 18,000 Gauss, delivering powerful suction and excellent separation performance.

- 1300mm magnetic separation surface width ensures high throughput and efficient operation.

- Features a strictly sealed magnetic structure with minimal magnetic leakage for enhanced safety and reliability.

- Entire unit constructed from 304 stainless steel for corrosion resistance, easy cleaning, and compliance with food processing standards.

- The original bulk grain distribution system ensures even material distribution, reducing reliance on vibrating feeders and lowering maintenance costs.

- The drive roller, magnetic roller, and tension roller undergo precision grinding to guarantee smooth, deviation-free belt operation.

- Equipped with a variable frequency controller, the rolling speed can be adjusted to accommodate different types and characteristics of grain seeds.

Technical data

| Model | 5CX-5 |

| Size L×W×H | 2050*1850*2200 mm(main machine) |

| Weight | 600 kg |

| Capacity | 5 T/H |

| Force | ≥18000 Gs |

| Voltage | 380V(220V/440V need customized) 50/60hz 3 phase |

| Power | Total:1.5 kw Bucket elevator motor:0.75kw roller motor: 0.75kw(frequency control) |

Grading machine

The grading machine is used for precise classification and screening of cocoa beans and other granular materials. Through multiple layers of customizable vibrating screens, it separates raw materials into different grades (typically 3-4 grades) based on bean length, width, or thickness. This ensures consistent particle size, enhancing the stability of subsequent processing steps and improving the quality of the final product.

Application value

- Screen aperture sizes can be customized to meet customer requirements, ensuring precise screening for various raw materials.

- Effectively removes oversized or undersized particles while retaining qualified material, guaranteeing uniformity and consistency in grading.

- Suitable not only for cocoa bean cleaning line but also for sorting granular materials such as coffee beans, nuts, grains, and coarse cereals.

Specification

- Power: 2.25kw

- Weight: 1000kg

- Dimension: 3400*2700*2700mm

Choose our cocoa bean cleaning line

Through these multiple cleaning and grading processes, cocoa beans undergo comprehensive purification and precise sorting before entering subsequent processing stages(such as the cocoa paste production line).

Our cocoa bean cleaning line not only highly efficient and reliable but also customizable to meet specific client requirements. If you are seeking solutions to enhance production efficiency and product quality, feel free to contact us anytime for detailed information and a quote.