The cocoa paste production line processes cocoa beans into high-quality cocoa paste (liquor/paste). This line can be customized to meet customer requirements, with capacities ranging from 50 kg/h to 2000 kg/h, suitable for small-scale processors to large-scale fully automated production lines.

The entire line automates roasting, shelling, and grinding processes, ensuring pure taste and rich flavor while offering simple operation and low maintenance costs. It stands as a crucial piece of equipment for deep cocoa bean processing.

High-temperature roasting fully develops the cocoa beans’ flavor profile. The shelling and grinding processes ensure the purity and uniformity of the cocoa solids, ultimately producing cocoa paste. This paste finds extensive applications in chocolate, cocoa beverages, desserts, and other food processing sectors.

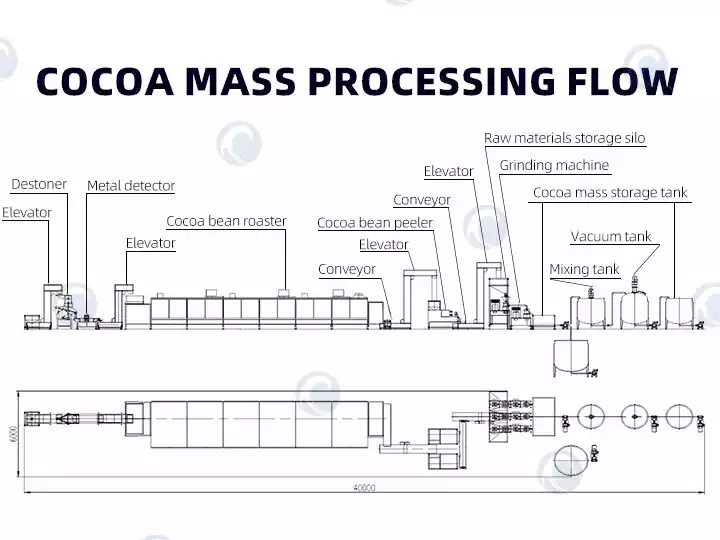

Whole process of cocoa paste production line

- Roasting: through controlled-temperature roasting, the flavor of cocoa beans is fully released, laying the foundation for subsequent dehulling and grinding.

- Peeling/Dehulling: the outer husk is removed, leaving only the cocoa nibs to ensure raw material purity.

- Grinding: the cocoa nibs are ground into a fine cocoa paste, also known as cocoa mass/liquor. This can be further cooled into solid cocoa liquor or used for cocoa butter extraction.

The following provides a detailed introduction to each machine of the cocoa paste production line.

Cocoa bean roasting machine

The cocoa bean roaster is a versatile machine widely used in processing cocoa beans and various nuts and seeds, such as peanuts, almonds, cashews, walnuts, coffee beans, and sunflower seeds. In cocoa paste production lines, the roaster serves as the initial processing step, playing a crucial role in enhancing cocoa flavor and ensuring product quality.

Structural and process features

- Rotating drum design: ensures uniform heating of materials, preventing under-roasting or over-roasting in localized areas.

- Multiple heat source options: supports gas or electric heating to accommodate diverse production requirements.

- Adjustable temperature and time settings: temperature reaches up to 300°C, with flexible baking time configurations to suit various roasting processes.

- Chain conveyor system: large-scale chain plate ovens utilize chain plates as the conveying platform, enabling continuous roasting.

- Cooling function: the cooling unit incorporates fans to provide uniform natural airflow, effectively lowering bean temperature and preparing them for subsequent cocoa paste production line shelling processes.

Operation and safety

- PLC automatic control: Siemens PLC control system precisely regulates temperature, time, and airflow velocity, enabling automated operation.

- Independent fire suppression system: continuously monitors the roasting environment, triggering immediate alarms upon anomalies to ensure production safety.

- Durable stainless steel construction: entire unit constructed from food-grade stainless steel, offering corrosion resistance, easy cleaning, and extended service life.

Cocoa bean peeling machine

The cocoa bean hulling machine is one of the core pieces of equipment in the cocoa paste production line, specifically designed to remove the shells from cocoa beans.

It ensures the integrity of the cocoa nibs while thoroughly separating the shells, achieving a hulling rate of 98%–99% or higher. With a production capacity of 200–500 kg/h, it operates stably and quietly, making it an ideal choice for automated cocoa processing plants.

Machine workflow

- Twin-roll shelling: roasted cocoa beans enter two counter-rotating rollers, where gentle compression cracks the shells while preserving the nibs intact.

- Vibrating screening: the broken mixture falls onto a three-layer vibrating screen for uniform dispersion and preliminary grading.

- Air separation: three fans activate, using directed airflow to blow away lightweight husks, leaving pure cocoa nibs.

- Closed-loop recycling: partially shelled beans automatically return via dedicated air ducts to the feed inlet for secondary shelling, minimizing raw material waste.

Core advantages

- High shelling rate: an automated recirculating shelling system achieves over 99% shelling efficiency.

- Precise airflow control: three independently adjustable fans ensure optimal separation performance.

- Low-loss design: maintains cocoa nib integrity during shell separation, minimizing broken kernels.

- Durability and efficiency: constructed from food-grade stainless steel for rugged durability, quiet operation, and easy maintenance.

Cocoa paste grinding machine

The cocoa grinding machine (colloid mill) is used to grind shelled cocoa nibs into fine cocoa paste. This equipment is not only suitable for cocoa paste production line but also widely applied in the fine grinding of materials across industries such as food, pharmaceuticals, and chemicals.

Working principle

- The grinder applies intense shear, friction, and grinding forces to materials through high-speed relative motion between the stator and rotor.

- As cocoa nibs pass through the stator-rotor gap, they undergo high-frequency vibration and high-speed vortex action, achieving thorough pulverization and uniform grinding.

- This process effectively disrupts cell walls, releasing internal cocoa components to produce a highly fluid, uniformly textured cocoa paste.

Grinding performance

- Achieves a maximum grinding fineness of 200 mesh, meeting the stringent taste and quality requirements for premium cocoa products.

- Grinding fineness is flexibly adjustable to accommodate diverse processing needs and product specifications.

- The resulting cocoa liquor is exceptionally smooth and refined, providing a solid foundation for subsequent processing into cocoa liquor blocks, cocoa butter, or chocolate products.

Cocoa liquor production line technical parameters

| Machine name | Power | Dimension | Capacity |

| Cocoa bean roaster | 18kw | 3000*1200*1700mm | 50-500kg/h |

| Cocoa bean peeler | 0.75kw | 1200*1100*1200mm | 200-500kg/h |

| Cocoa bean grinder | 7.5kw | 750*450*1000mm | 300-1200kg/h |

Optional equipment for cocoa mass processing line

Homogenizer machine

The homogenizer installed after the cocoa paste grinder is primarily used to further refine and homogenize the cocoa paste.

- It breaks residual particle clusters through high shear force and evenly distributes fats, yielding a smoother, more stable cocoa paste.

- Adjustable pressure and flow rate allow flexible control over fineness, ensuring the product meets the quality requirements for premium chocolate, cocoa butter, and cosmetic ingredients.

- Significantly enhancing taste, texture, and storage stability, it is a crucial component of high-quality cocoa paste production lines.

Storage jar

Storage tanks are used to receive and stabilize processed cocoa paste, ensuring continuous production and consistent product quality.

- The tanks feature insulation and stirring functions to maintain paste temperature and uniformity, preventing separation and clumping.

- This effectively reduces oxidation and extends raw material shelf life.

- They are often used in conjunction with mixing tanks and vacuum tanks: mixing tanks serve as buffers and for formulation adjustments, while vacuum tanks are used for degassing to remove micro-bubbles and extend shelf life. Storage tanks are employed for final stabilization and preservation.

Why choose our cocoa paste production line?

- Zero waste, high efficiency: equipped with a closed-loop shelling system that automatically identifies and recycles incompletely shelled cocoa beans for secondary processing, minimizing raw material waste.

- Flexible customization: supports comprehensive customization, allowing not only adjustable production capacity but also the freedom to select or modify various single-machine configurations within the production line according to customer requirements.

- Seamless integration: seamlessly connects with front-end cocoa bean cleaning and grading production lines while flexibly expanding with back-end cocoa powder processing lines, delivering an integrated processing solution.

This highly automated and flexibly customizable cocoa paste production line enables you to consistently and efficiently produce high-quality cocoa liquor blocks while seamlessly integrating upstream and downstream processes. It achieves fully integrated production from raw material processing to deep processing.

Whether for chocolate, beverages, or applications in the food and cosmetics industries, this production line is the ideal choice for boosting your production capacity and enhancing product value. Contact us anytime!