食品の安全性は現代世界において最も重要な関心事です。食品の安全性と長期保存を確保するために、さまざまな滅菌方法や滅菌装置が開発され、市場に出回っています。この記事では、現在入手可能なさまざまなタイプの食品殺菌機、特に UV 殺菌機に重点を置いて詳しく説明します。

食品殺菌機の種類

食品加熱殺菌装置

加熱殺菌は食品の保存に使用される最も伝統的な方法の 1 つです。主なタイプは次の 2 つです。

煮沸と低温殺菌: この方法では、有害な微生物を殺すために食品を特定の温度に加熱します。乳製品、ジュース、缶詰などによく使われます。

オートクレーブ: 主に缶詰産業で使用されるオートクレーブは、高圧蒸気を食品容器に適用し、細菌、ウイルス、胞子を効果的に破壊します。

化学食品殺菌装置

化学的滅菌は、微生物の増殖を殺したり抑制したりするためにさまざまな化学物質を使用することに依存しています。一般的な方法には次のものがあります。

塩素化: 塩素系化合物は、食品加工施設の水と表面を消毒するために使用されます。

照射: 電離放射線は、食品内の細菌や寄生虫を破壊し、保存期間を延ばすために使用されます。

ろ過装置

濾過装置は物理的バリアを使用して食品から微生物を除去します。一般的な方法には次のようなものがあります。

精密濾過: 微細孔を利用して細菌や酵母を捕らえ、除去します。

限外濾過: より大きな孔を備えた膜を使用して高分子と粒子を分離します。

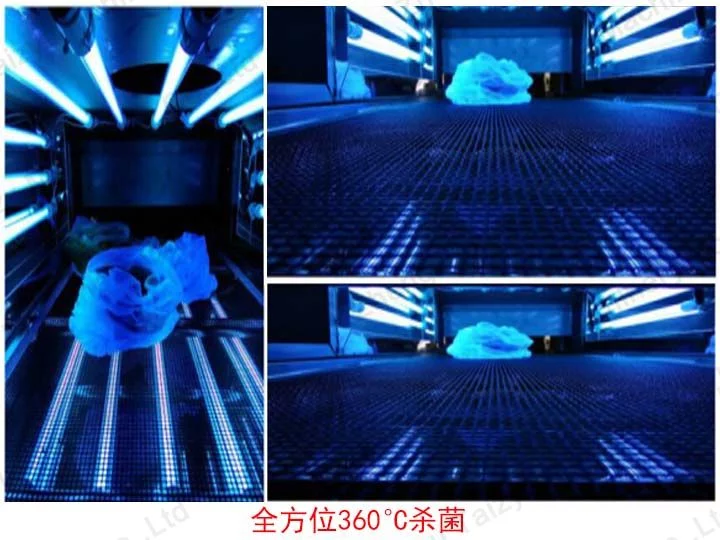

UV滅菌機

UV滅菌は、非熱的かつ化学薬品フリーであるため、近年人気が高まっています。UV食品滅菌機は、紫外線(UV-C)を使用して微生物のDNAを破壊し、複製能力を奪い、死滅させます。UV光を使用して食品を衛生的にすることは、経済的かつ迅速な方法です。

UV殺菌の仕組み

紫外線滅菌機は、波長200〜280ナノメートルのUV-C光を放射します。この特定の波長は、微生物の DNA と RNA を破壊するのに非常に効果的で、微生物の繁殖能力を妨げます。 UV-C ライトは、病原体の遺伝物質に損傷を与え、それらを無害にする働きがあります。

食品業界における UV 滅菌の応用

UV 殺菌機は、食品産業のさまざまな側面で応用されています。

- 水処理: UV システムは食品加工に使用される水を滅菌するために使用され、化学消毒剤の必要性を排除します。

- 表面の消毒: UV ランプを使用して食品加工施設の表面や機器を消毒し、相互汚染のリスクを軽減します。

- 包装: UV 滅菌機を使用して包装材料を消毒し、保管および輸送中に食品が汚染されていないことを保証します。

- 空気殺菌: UV-C ランプを空気処理ユニットに設置して、食品加工エリアの空気を殺菌し、空気感染のリスクを軽減できます。

UV滅菌のメリット

- 化学物質不使用: UV-C 光は残留物や化学物質の痕跡を残さず、食品の安全性と品質を保証します。

- エネルギー効率: UV 滅菌機は、熱ベースの方法と比較して比較的少ないエネルギーを消費します。

- 環境に優しい: 化学副生成物や排出物がないため、UV 滅菌は環境的に持続可能です。

- メンテナンスの軽減: UV ランプは寿命が長く、メンテナンスは最小限で済みます。

食品の安全性が最も重要である世界では、食品殺菌機の選択が重要です。さまざまな方法が利用可能ですが、UV 滅菌機は効率的で環境に優しく、化学薬品を使用しないオプションとして際立っています。これらの機械は、食品業界の水、表面、包装材料、空気を消毒する安全で信頼性の高い手段を提供します。技術が進歩し続けるにつれて、食品殺菌の分野ではさらに革新的なソリューションが登場すると予想されます。