世界中で愛されているスナックであるポテトチップスは、私たちの熱心な味覚に届くまでに、細心の注意を払った製造プロセスを経ます。この包括的なガイドでは、ポテトチップスの製造プロセスに含まれる複雑な手順を詳しく説明し、農場から最終包装に至るまでのあらゆる段階についての洞察を提供します。控えめなスパッドから、私たちが大好きなサクサクで満足のいくチップスまで、サクサクした味わいの旅を一緒に探索しましょう。

ジャガイモの選別と収穫

ポテトチップスの製造プロセスにおける最初の重要なステップは、高品質のジャガイモを慎重に選択して収穫することです。農家は適切なジャガイモの品種を選択することに細心の注意を払い、それがチップス生産の特定の基準を満たしていることを確認します。ラセット、アトランティック、スノーデンなどの品種は、でんぷん含有量が高く糖度が低いため、最終製品の望ましい味と食感に寄与するため、一般的に好まれています。

洗浄と剥離

収穫後、ジャガイモは汚れや不純物を取り除くために徹底的に洗浄されます。洗浄プロセスは原材料の清潔さと衛生を保証するために極めて重要です。その後、ジャガイモは丁寧に皮をむかれ、皮は廃棄物を最小限に抑え資源利用を最大化するために他の用途へ再利用されることが多いです。多くの ポテトチップス処理ライン はこの工程を実行するためにポテト洗浄機と皮むき機を使用します。

スライスと湯通し

皮をむいたジャガイモは次にスライス工程へ進み、専門的な ポテトスライサー によって薄く均一なスライスに正確にカットされます。これらのスライスはすぐに熱水に浸されるブランチング処理を受けます。ブランチングには過剰なデンプンの除去、スライスの事前調理、バッチ全体で均一な色と食感を確保するなど、複数の目的があります。

揚げ物と味付け

ブラン blanchされたジャガイモのスライスは、ポテトチップス揚げ機で特定の温度で慎重に揚げられ、完璧なサクサク感と黄金色を得ます。この工程は ポテトチップス に特徴的な食感と味を生み出すために不可欠です。揚げた後、塩、香辛料、独自ブレンドなどを含むさまざまな風味を加え、魅惑的なフレーバーの多様なラインナップを作ります。

冷却と梱包

味付けが完了すると、熱々のチップスは急速に冷却され、サクサクした食感が保たれます。冷却後、チップはパッケージング段階に移動し、高度な機械によって気密かつ耐湿性のパッケージにチップが効率的に封入されます。このステップは、チップスの新鮮さとサクサク感を保ち、製造から消費まで魅力的な状態を維持するために不可欠です。

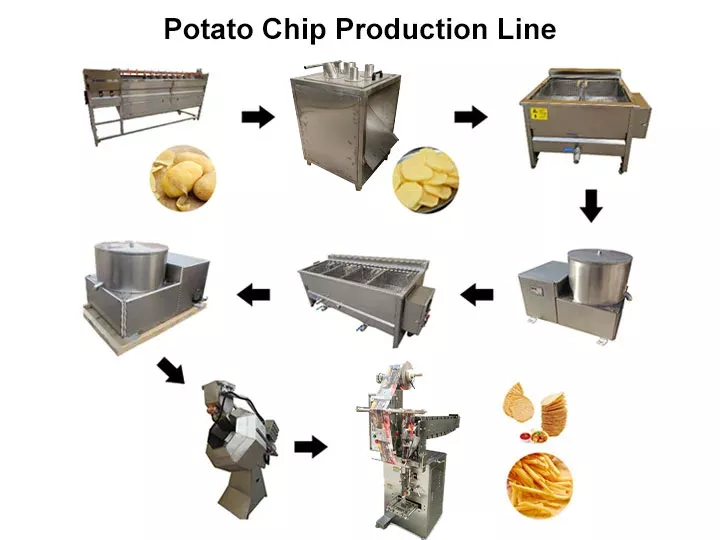

ポテトチップス加工ラインのポテトチップス製造装置

ポテトチップス加工ラインの主なポテトチップス製造設備は、ジャガイモ洗浄機、ジャガイモ皮むき機、ジャガイモスライス機、ジャガイモ湯通し機、ポテトチップスフライ機、ポテトチップス味付け機、ポテトチップス包装機です。

ポテトチップスの製造プロセスは、正確な技術、革新的な技術、品質管理手段が調和してブレンドされており、すべて一口ごとに完璧な歯ごたえと風味を提供することを目的としています。ジャガイモの入念な選択から細心の注意を払った包装に至るまで、各段階が世界中の何百万もの人々に楽しんでいるおいしいスナックの創造に貢献しています。それで、次にポテトチップスの袋を味わうときは、この謙虚なスパッドがあなたの指先に届くまでに費やした複雑な旅を思い出してください。