This press is a commercial screw press machine. It has the characteristics of reasonable design, advanced technology, and wide application. According to the internal structure of the machine, our company divides the machine into a single screw press, a double screw press, and a special screw press. This machine is suitable for juice pressing and dehydration of various materials containing certain fibers. However, due to the different requirements of material properties, particle size, density, and dryness, the application scope of the machine is slightly different. The properties, granularity, and density of materials are certain. So how to judge the dryness requirement of materials?

Method for judging material dryness (water content):

Water content is about 60%: Hold the material hard with your hand, and you can’t hold the water.

Water content is about 70%: Hold the material hard by hand. There is water between fingers, but it won’t drip.

About 80% water content: Hold the material with your hand, and the water can flow down.

Double screw press machine:

Introduction:

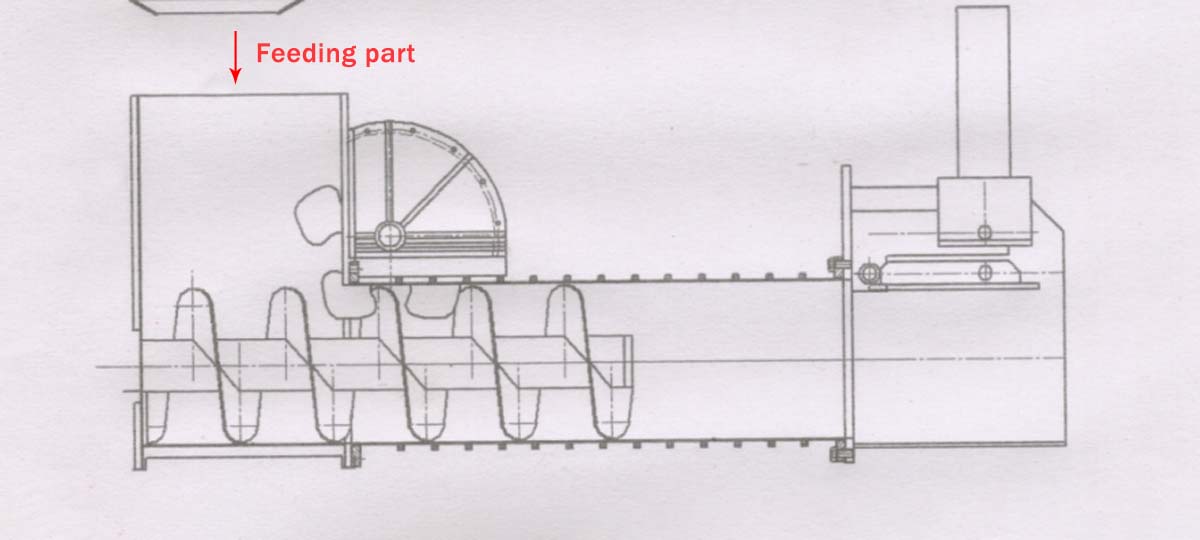

The double-screw press machine has two snails inside the machine. According to the arrangement of the screw, the machine can be divided into a parallel double screw press and a tandem double screw press. You can choose different spiral forms depending on the material and output.

- Parallel: The left and right cross each other for reverse rotation, and the two pressing screws are respectively placed on different main shafts.

- Tandem: A structure in which the conveying screw and the pressing screw are connected in series for reverse rotation.

Difference:

- The series double-screw press machine has a simple structure and low cost and is suitable for pressing fiber-containing fruits and vegetables. Particularly suitable for use in the wine-making industry. It is not suitable for materials with high sugar content, low fiber content, and fluidity. It is easy to make the machine slip and it is impossible to push the material out of the machine. In addition, particularly coarse fibers such as roots cannot be used.

- Parallel double-screw press machine rotation speed is fast, the back resistance is large, the cost is high, and the material exit is easy to block. The technology of this machine is relatively old, and most fruit and vegetable manufacturers no longer use it. It is mostly used for the separation and tear of meat and feathers in poultry.

Double screw press features:

Applicable to:

It is suitable for juicing grape peel residue, seabuckthorn fruit, ginger, and other fruits and vegetables after fermentation. It is the most preferential squeezer at present. However, it has low yield and efficiency and has certain limitations on materials, so it is not widely used.

Not applicable to:

- Contains fluid and slippery materials.

- The particles are less than 10mm sugary fruits and vegetables.

- Chinese medicine slag with particles larger than 10mm.

Double-screw press machine parameters:

| Type | ZKY-S1.5 | ZKY-S5 | ZKY-S10 |

| Production capacity(t/h) | 1.5 | 5 | 10 |

| Size(mm) | 1900*600*1200 | 3500*1000*1300 | 3750*960*1300 |

| Power(kw) | 7.5 | 7.87 | 11.37 |

Single screw press machine:

Working principle:

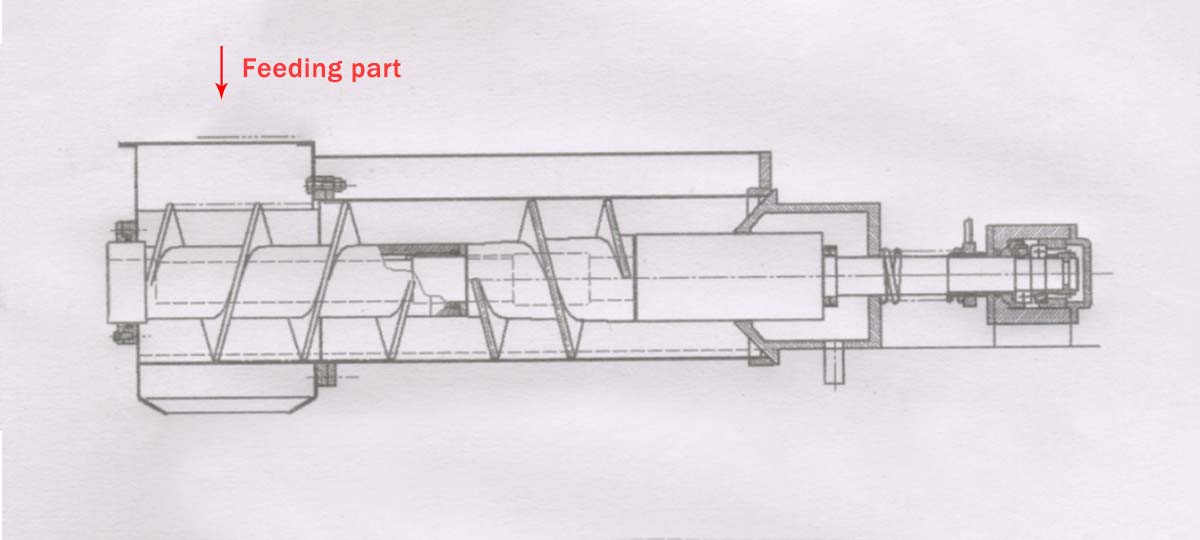

The machine is composed of a frame, a transmission system, a feeding part, a juice extracting part, a hydraulic system, a protective cover, and an electrical control part. After crushing, the material is fed into the feeding box, and under the action of the forced feeding plate, it enters the squeezing chamber. The juice extracted by the screw Juicer flows into the juice tray through the sieve barrel, and the crushed residue is discharged by the forced door at the end of the sieve barrel.

The single screw press uses the principle of forming a pressing layer by extruding the spindle screw, screen barrel, and press door to dehydrate. When the forced door is opened, it is necessary to pay attention to the dryness of the discharged waste. The dryness of the waste residue should be wetter than the last required dryness, otherwise, the machine will be blocked.

Application market of screw juicer:

- All kinds of Chinese medicine residues. (The sticky and slippery material after fermentation is not suitable)

- Fruits and vegetables containing certain fibers, such as vegetables and fruits, fresh grapes, fermented grapes, Seabuckthorn fruits, and pineapples.

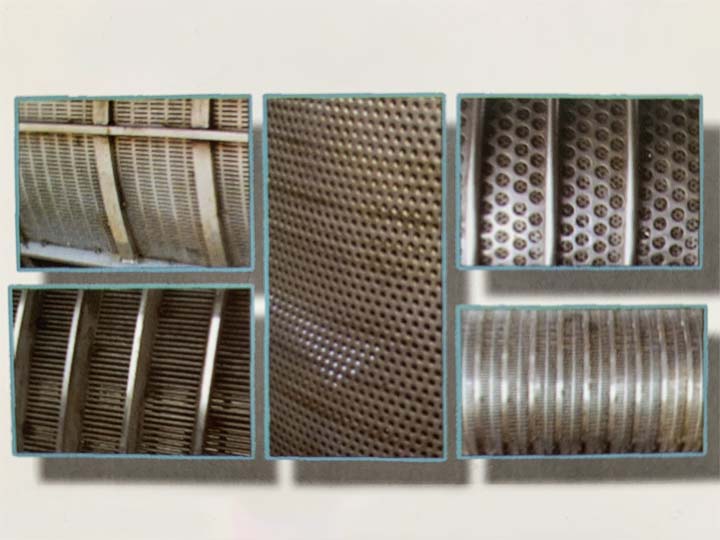

- Dehydration of plant stems and roots such as corn straw.

- Unfermented garbage in vegetable market.

- Medical plastic waste.

- 100% fiber pulp residue, coarse (cotton) fiber black juice extraction.

Single screw press machine:

- The machine adopts German gear transmission technology, with large torque, low noise, and scientific physical extrusion.

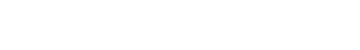

- The sieve barrel is made of trapezoidal wire and externally added with reinforcing ribs. The sieve bucket is divided into the split type and complete type. The split type is easy to disassemble, while the complete type has a stronger pressure resistance, and itis convenient for washing.

- The machine is equipped with a forced feeding plate to speed up the feeding speed, prevent returning and slipping.

- Unified discharge, uniform dryness. If the material has a high water saturation and the sieve barrel diameter exceeds 500 mm, use a special screw press machine.

- The device has the characteristics of high pressing strength, large bearing pressure, no deformation, no clogging, corrosion resistance, wear resistance, convenient maintenance, and long service life.

Single screw press machine parameters:

| Production capacity (t/h) | Hydraulic system pressure (Mpa) | Motor Power

(KW) |

Weight

(KG) |

Size

(mm) |

| 1.5 | 1-5 | 4 | 800 | 2565*480*905 |

| 3 | 1-5 | 4 | 1200 | 3200*560*1120 |

| 5 | 2-6 | 7.5 | 2000 | 4100*900*1500 |

| 10 | 2-8 | 15 | 2500 | 4620*920*1550 |

| 20 | 2-8 | 18 | 3000 | 4950*1100*1730 |

| 40 | 2-10 | 22 | 4500 | 6000*1200*2000 |

Special screw press machine:

Introduction:

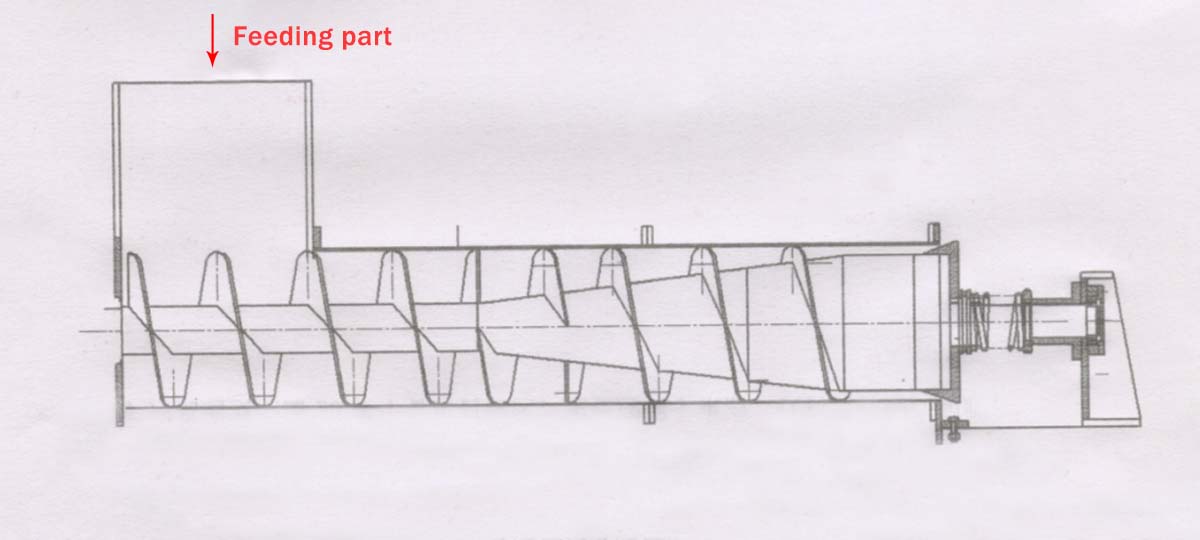

Special screw juicer is also called screw dehydrator, screw juicer, variable diameter screw juicer. It has all the advantages of single-screw and double-screw press machine. The machine deals with viscous and slippery fluid materials by changing the aperture of the screen barrel, the shape of the helix and the rotational speed. It also has a good dewatering effect on materials that are difficult to handle on other machines. For example, a relatively smooth and viscous material containing colloidal proteins, oils and the like. This machine is used in a wide range of applications and covers almost all industries that have “solid-liquid separation” process requirements. The water content of the material after dehydration by the machine is ≦60%.

Special screw press machine application range:

- Juice extraction of roots, stems, leaves, flowers, fruits, and other materials of fruits and vegetables. Such as red dates, apples, pears, sweet potatoes, potatoes, pineapples, seared fruits, blueberries and other berries, sea buckthorn with branches. Flowers such as peony, roses, etc.

- Dehydration of various waste residues, such as copra, various Chinese medicine slag, various tea residue, vinegar grains, various distiller’s grains, cassava residue, waste after coffee extraction, corn husk, slag residue, fish carp, shrimp residue, Chicken feathers, chicken slag, etc.

- Separation of kitchen waste, domestic garbage, and vegetable market waste, as well as the separation of fermented food waste, biogas residue, organic matter, and inorganic matter.

- 4. Dehydration of various dung, such as pig manure, cow dung, duck dung and so on. (solid, liquid can be)

- Sludge slag, dewatering of pulp slag, press recovery of medical plastics and gelatin slag.

Special screw press machine:

- The internal propeller, not only to prevent the phenomenon of material return but also play a role of slight breakage. It can realize crushing and pressing in one machine, save space and save equipment investment.

- The screw of our company adopts special structure feeding plate, and the screw adopts double-leaf pushing type. So that it can realize smooth delivery of materials, uniform dry humidity, and fast pressing speed.

- According to the material condition, we can design several pressing screws in series to realize step-by-step pressing and dehydration more thoroughly.

- Install a stirrer inside the machine to prevent external drying and internal wetting when the diameter of the helix is greater than 500 mm.

- According to the need, our company press machine can pass steam, hot water, solvents, ethanol and so on inside the machine.

- Our company’s press mainly achieves the separation of free water in the material. For the combined water, the object needs to be broken. Pressing AIDS may be added to some waste materials: lime, alum, gypsum, corn husk, rice bran, etc. In order to achieve more thorough dehydration.

- The press screen has a self-cleaning function and is not easily blocked.

- There are fewer consumable parts that need to be replaced, and the maintenance cost is low. Every time we encounter a problem, there are technical improvements, and the wearing parts are almost zero. Some of the presses have not been repaired for eight years.

- The stainless steel trapezoidal filter has high strength, wear-resistance and corrosion resistance, long service life and good filtration performance.

- Our company’s technology for manufacturing screw press is close to 20 years. We are very familiar with the properties of hundreds of materials and can provide customers with economical and reliable screw press machines.

Special screw press machine parameter:

| Production capacity (T/H) | Motor power (kW) | Weight (kg) | Size (mm) |

| 0.8-1 | 4 | 230 | 1950*510*740 |

| 1.5 | 7.5 | 1200 | 2400*600*1100 |

| 3 | 15.5 | 2400 | 4100*850*1500 |

| 5 | 18.5 | 3000 | 4900*920*1700 |

| 10 | 22 | 3700 | 5200*1000*1870 |

| 20 | 30 | 5000 | 6500*1200*2000 |

If you need our screw press machine, welcome to contact Taizy food machinery.

Add Comment