The peanut butter making machine, also known as the colloid mill, is a machine for making peanut butter or sesame butter. This machine is made of food-grade stainless steel with high quality and reasonable price.

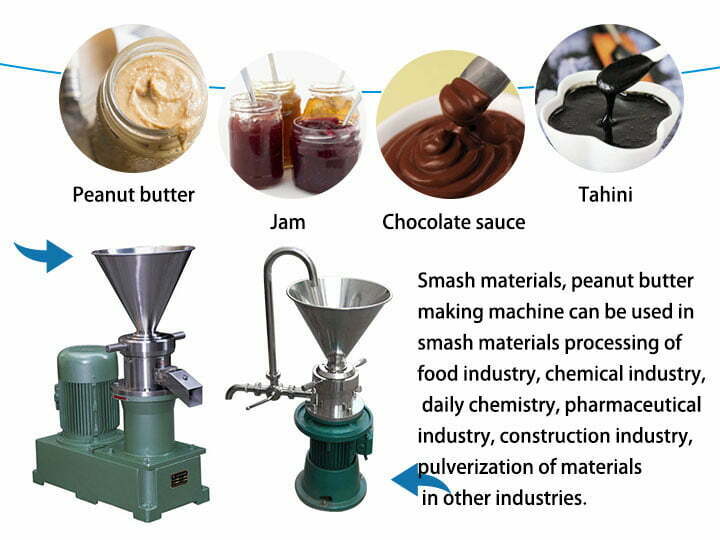

Overview and Use of Peanut butter Making Machine

Peanut butter making machine is a machine for refining fluid materials. Its structural form is the first in China. It is not only advanced in design but also can adjust the rotation speed of the grinding head according to the requirements of the materials to be processed. For different processing objects and processing environments, the motor can be replaced at will. The main technical indicators have reached an advanced level of domestic similar products. The machine has superior superfine grinding, dispersing, emulsifying, homogenizing, and mixing functions. The particle size of the material can reach 2-60 microns after grinding, and the homogeneity can reach more than 95%. It is a piece of ideal equipment for ultra-micro-processing. It integrates the functions of a homogenizer, ball mill, three-roll mill, mixer, and other machines. Its efficiency is several times higher than that of the above machines. It can be widely used in food, medicine, chemical industry, cosmetics, light industrial plastics, and other industries.

Working Principle of Peanut Butter Making Machine

The peanut butter making machine consists of a grinding disc (rotating member) and a grinding surface (fixing member). And there is an adjustable small gap between the two parts. When passing through the gap between the two parts, the material to be processed generates a downward rotational pressure by external pressure. At this point, the material is subjected to intense friction to produce a micronization effect. The material is pulverized and emulsified. By the way, peanuts need to be roasted in a peanut roaster before they can be made into peanut butter

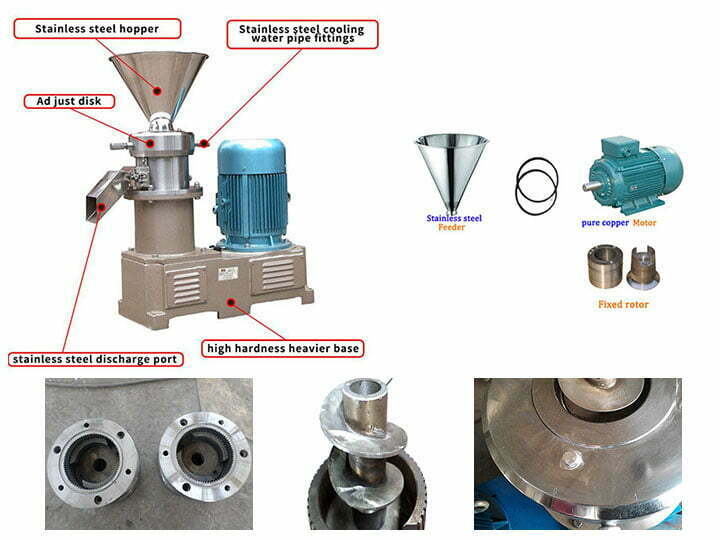

Structural characteristics of Peanut Butter Maker

This peanut butter making machine not only keeps the traditional peanut butter maker reasonable in structure, simple in operation, convenient in maintenance, small in volume, and light in weight. It also has the characteristics of wide adaptability, and simple speed change, and can replace different types of motors for different processing objects.

- The main parts of the machine are made of stainless steel, which is corrosion-resistant and non-toxic.

- The main working parts of the machine are divided into stator and rotor, which are well-processed. The clearance between the stator and rotor can be adjusted slightly by the positioning plate. It is equipped with a dial, which is easy to control and ensures the quality of product processing.

- According to different uses, stators and rotors of different materials can be selected for. And it is easy to disassemble.

- The speed of the machine can be adjusted. The user can order the appropriate speed according to the material processing conditions.

Type and Main Technical Parameters

| Type | JM-50 | JM-85 | JM-130 | JM-210 |

| The fineness of object processing(um) | 2-70 | 2-70 | 2-70 | 2-70 |

| Motor power(kW) | 1.5 | 5.5 7.5 | 7.5 11 | 30 |

| Output (self-inflow) r/min | 0.2-0.8 | 0.2-4 | 0.2-6 | 2-6 |

| No-load speed(cm) | 3000±100 | 3000±100 | 3000±100 | 3000±100 |

| Size(cm) | 50*23*70 | 105*30*84 | 127*38.5*102.5 | 120*50*130 |

| Weight(kg) | 60 | 185 | 240 | 600 |

| Remarks | Equipped with a cooling system | Equipped with a cooling system | Equipped with the cooling system | Equipped with a cooling system |

Installation and Use Precautions and Maintenance:

-

- The equipment is installed horizontally on the flat concrete foundation and fixed with the anchor screw (it can also be not fixed according to the working conditions).

- Check if the fastening screws are tightened.

- Before use, use a special wrench to turn the rotor to check whether it is in contact with the stator, and if there is any jam, it is not allowed to start the machine.

- Check and connect the power cord (three-phase AC, voltage 380 volts, body protection ground) and note that the direction of rotation of the rotor should be the same as the arrow on the base (clockwise rotation).

- Turn on the cooling water and pay attention to the water inlet and outlet signs.

- When starting the motor, first click the switch to check if there is noise or vibration. If the situation is not normal, stop it immediately. After troubleshooting, try again.

- When cleaning the residual materials in the stator and rotor after work, it should be carried out under rotation. First, the positioning disk is rotated counterclockwise by not less than 90° and then washed.

Method of adjusting clearance between stator and rotor

(adjusting should be carried out in operation):

A. Release the two handles.

- The handle is moved to drive the positioning disc to rotate, and the gap is adjusted. The positioning disc rotates clockwise and the gap is small, and the material granularity is thin. The counterclockwise rotation gap is increased, and the material size is coarse.

- After adjusting the clearance between the stator and rotor, two handles should be tightened at the same time. (Clockwise)

- According to the granularity and batch requirement of the processed material, the limit screw can be adjusted to reach the limit after selecting the best stator to rotor clearance.

Requirements for processing materials:

- Can not process dry solid materials, only wet processing.

- Before the material is ground, the impurities should be removed. The particle size should be less than 1mm. The hardness of the material should not be higher than HV309. Hard objects such as iron and gravel particles are strictly prohibited from entering the grinding head to prevent damage to the peanut butter making machine.

- One or more grindings may be performed according to material processing requirements. Several tests shall be performed before grinding to ensure optimum clearance and flow.

- Always pay attention to the working condition and running time when using. In case of abnormal conditions, the peanut butter making machineshould be shut down immediately and dismantled for inspection.

Matters needing attention:

- If the colloid mill is used or not used for a short period of time, the inner cavity should be cleaned well to prevent rust. It is best to dry it with high-pressure air. When cleaning, select a suitable cleaning agent according to different materials. However, it should be ensured that the seal is not damaged ( The seals are made of nitrile butadiene rubber).

- The disassembly type should pay attention to the sealing rings should not be damaged, misassembled, or lost.

- When replacing the pulley according to the required number of revolutions, first loosen the motor cover end nut, turn the tensioning screw to the left, and push the motor in the direction of the grinding head in the horizontal direction to relax the V-belt.

- After the peanut butter making machine is erected, the motor is driven along the horizontal direction, and the tightening screw is rotated to adjust slightly so that the triangular belt is tightened, and then the cover plate is fixed.