With the development of society, it is a new fashion of a healthy diet to eat coarse grains. The multifunction pasta machine is not only in line with people’s healthy diet concept, but also leads people’s consumption concept. It produces low-fat, low-calorie, healthy and fashionable products.

Introduction of Pasta Machine:

The machine is precise in the manufacture, beautiful in appearance, convenient in use, low in cost, low in power consumption and high in output. It is an ideal investment product. Multifunction pasta machine can produce various kinds of food through different molds: shell shape crisp, twist slices, hollow noodles, Tremella crisp, pentagonal shape crisp, cat ear shape crisp, screw noodles, lantern shape crisp, conch shape crisp, pasta, macaroni and so on.

Place of application:

Because of its simple operation, convenient mold replacement, and delicate taste. The multifunction pasta machine is widely used in school canteens, food processing factories, supermarkets, and other places.

Advantages of the multi-function pasta machine:

- A variety of pasta can be made and the mold change is simple.

- It can produce pasta with different colors to attract customers’ eyeballs. And it will cause customers’ curiosity and desire to purchase. For example, if you want to produce a green product, you can add spinach juice or edible pigments to adjust the color.

- The cut product is not easy to deform. The cut surface is smooth. And the thickness and specifications are the same.

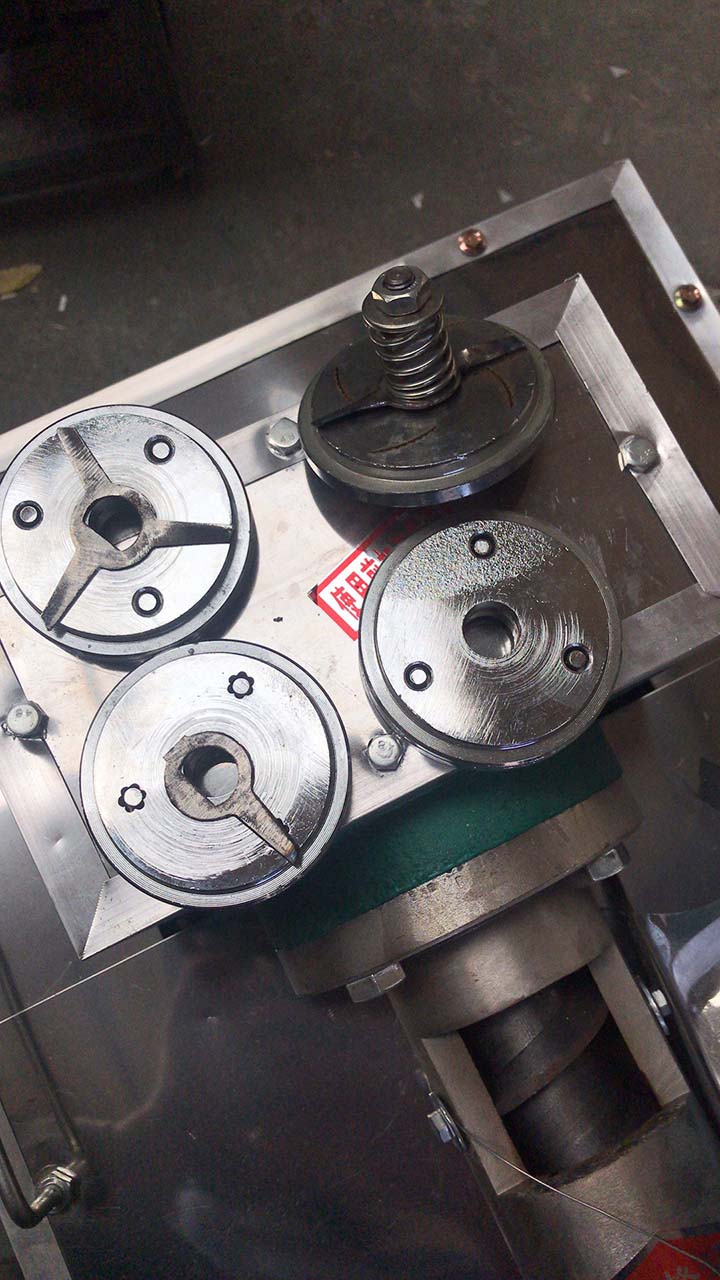

- The whole body of the machine is made of high-quality 304 stainless steel, which is beautiful in appearance and meets the national food hygiene standards.

Usage method of Pasta Machine:

- Open the nut with a special wrench and take out the screw rod. Wipe the bucket and the screw rod clean, and then put the screw rod into the sleeve. Align the drive keys on the screw rod to the “swing” slot and install them to the end. After cleaning the tool, choose the ideal tool to install in the front of the machine, screw the nut, and tighten it with a special wrench.

- Connecting the power supply, and the pasta machine can be used without abnormal sound after idling for several minutes.

- After each use, unload the nut, take out the cutter, and soak the cutter in water for cleaning. And the remaining dough block can be turned out after a few revolutions. Then stop the machine, gently raise the screw rod with a special wrench, then pull out the screw, and clean the sticky surface of the inner wall of the sleeve, clean the slag in the nut, and clean the dough block in the groove at the front end of the screw.

- Attention: If it is not cleaned up, the residual flour slag will dry out, and the dry dough slag will block the outlet, so the finished product can not be processed. Overloading will cause nut breakage or even damage the gearbox, motor, etc.

Do not lubricate with thin oil. Fill the gearbox with lubricant once every three months (one kilogram of butter).

Parameter of the Multi-function Pasta Machine:

| Type | Productivity

(kg/h) |

Power

(kW) |

Size

(mm) |

Weight

(kg) |

| MST-30 | 30-35 | 60-70 | 100-105 | 140-150 |

| MST-60 | 1.5-2.2 | 2.2-3 | 4 | 7.5 |

| MST-100 | 450*790*960 | 500*500*960 | 500*600*920 | 500*650*960 |

| MST-150 | 80 | 110 | 125 | 155 |

Schedule: Processing of Shell Shape Crisp

Pretreatment of raw materials and auxiliary materials – Stirring and ripening – Processing by pasta machine – Frying – Cooling – Packaging – Finished products.

Pretreatment of raw materials and auxiliary materials:

weigh the flour well, and sift it to remove impurities. And weigh salt, alkali, and water in a certain proportion (water temperature is about 20℃). Mix salt and alkali with water at the same time, stir them into the whole solution and pour them into the flour.

Mix and ripen the prepared flour:

When mixing and operating on the machine, keep the indoor temperature above 10℃, stir for 20 minutes to the dough shape (20-30℃), so that the dough can absorb water sufficiently. Expanded to form a gluten network, placed for 10 minutes, keep the temperature of the dough 20-30℃, and then go to the machine. (Conditionally can be stirred by a motor mixing barrel).

Note: In the stirring process, if the alkali, salt solution and stirring temperature are too low, the dough shape will not be gluten network organization, and the shell will not be crisp. On the contrary, if the temperature of alkali and salt solution and the stirring temperature is high, the dough gluten will be aged and the dough will be prematurely matured. The above situation will also occur, so it must be operated as required.

Processing by pasta machine:

Put the stirred dough into the shell making During the repeated roll-rolling process, the dough is made into shell shape and then put into the die plate to prepare for the frying process. The machine is automatic quantitative partitioning, and the size of the pasta produced is the same.

Frying:

Put the quantitatively cut shells into a hot oil pan (oil temperature is kept at about 180℃), fry for 1 minute.

Note: It is best to use palm oil (or vegetable oil mixed with lard in a ratio of 1 to 1). The highest oil temperature is 200℃ before cooking and 170℃ after cooking.

Video:

How to make pasta?