أخبار رائعة! لقد سلمنا آلة تعقيم بالأشعة فوق البنفسجية بطول مترين لشركة معالجة الأغذية في الإمارات العربية المتحدة. يتخصص هذا العميل في معالجة وتصدير الأطعمة المعدة، والفواكه المجففة، والمشروبات، والأطعمة المعبأة، مع الحفاظ على قنوات مبيعات مستقرة عبر الإمارات والأسواق المجاورة.

يهدف العميل إلى تعزيز معايير السيطرة على الميكروبات من خلال معدات التعقيم هذه، لضمان بقاء الأطعمة المعبأة ذات مستويات عالية من النظافة والسلامة طوال عملية الإنتاج والتوزيع. وفي الوقت نفسه، يسعى لتحسين أتمتة خط الإنتاج وكفاءة التشغيل.

ميزات المعدات والمزايا الفنية

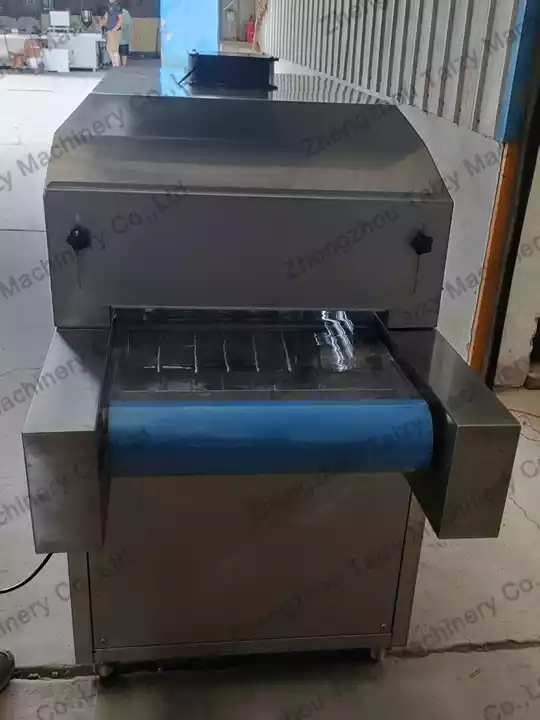

آلة التعقيم بالأشعة فوق البنفسجية التي تم تسليمها لها طول إجمالي 2 متر، ومساحة عمل 1000مم، وأبعاد المدخل/المخرج 500مم لكل منهما. ارتفاع المدخل قابل للتعديل (200مم)، مع وضع حزام الناقل على ارتفاع 750±20مم فوق مستوى الأرض. تعمل على كهرباء 220 فولت أحادية الطور، وتوفر تشغيل بسيط وأمان موثوق.

- تعقيم عالي الكفاءة: يستخدم الضوء فوق البنفسجي للقضاء بسرعة على الكائنات الدقيقة على أسطح الطعام والتعبئة، بما في ذلك البكتيريا والعفن، مما يطيل عمر الرف.

- تشغيل مستمر آلي: يدمج بسلاسة مع خطوط الإنتاج الحالية للتعقيم المستمر على الناقل، مع تقليل التدخل اليدوي.

- كفاءة في استهلاك الطاقة وصديقة للبيئة: استهلاك منخفض للطاقة مع إدارة قابلة للتحكم في الطاقة، صيانة بسيطة، ومناسبة للتشغيل طويل الأمد وعالي الكثافة.

- معايير سلامة الغذاء: مصنوعة من مواد غذائية، وتصميم مدمج بأقل مساحة، ومتوافقة مع متطلبات صحة الغذاء للتصدير.

سيناريوهات تطبيق آلة التعقيم بالأشعة فوق البنفسجية

هذه آلة التعقيم بالأشعة فوق البنفسجية مناسبة لمختلف الأطعمة المعبأة والمنتجات المعالجة، بما في ذلك:

- تعقيم أسطح الأطعمة المطهية والمبردة

- تعقيم الفواكه المجففة والمكسرات

- تعقيم أسطح زجاجات المشروبات أو عبوات التعبئة والتغليف

- تعقيم أسطح المخبوزات وتعبئة الوجبات الخفيفة

من خلال دمج هذا المعدات في خطوط الإنتاج، يحقق العملاء رقابة عالية المستوى على النظافة طوال العملية من المعالجة إلى التعبئة.

التعاون والدعم الفني

خلال مناقشات المشروع الأولية، قدم العميل تفاصيل عن تخطيط خط الإنتاج، وأنواع المنتجات، ومتطلبات الإنتاج اليومي. قدم فريقنا الفني حلول معدات مخصصة تلبي احتياجاتهم الخاصة، بما في ذلك مواصفات طاقة مصباح الأشعة فوق البنفسجية، وخطط تعديل سرعة الناقل، وتصميمات حراس الأمان، لضمان الكفاءة والسلامة.

كما زودنا العميل بكتيبات التشغيل الشاملة، وإرشادات التركيب، والدعم الفني عن بعد لمساعدته على إتقان تشغيل المعدات بسرعة وتحقيق إطلاق إنتاج سلس.