Cette machine électrique de torréfaction continue des noix à chaîne et bande utilise un système de convoyage à chaîne et bande, équipée d’un système de chauffage à température contrôlée automatique et d’un puissant dispositif de circulation d’air chaud interne. Elle permet à un air chaud à haute pression et contrôlable de pénétrer uniformément dans les couches de matière, améliorant considérablement l’efficacité et l’uniformité de la cuisson.

Comparé aux machines de torréfaction traditionnelles, cette unité offre des résultats de cuisson uniformes, une texture croustillante et une saveur authentique. Elle est également économe en énergie, respectueuse de l’environnement, simple à utiliser et offre des performances stables, répondant pleinement aux normes d’hygiène de l’industrie alimentaire et aux exigences d’exportation internationales.

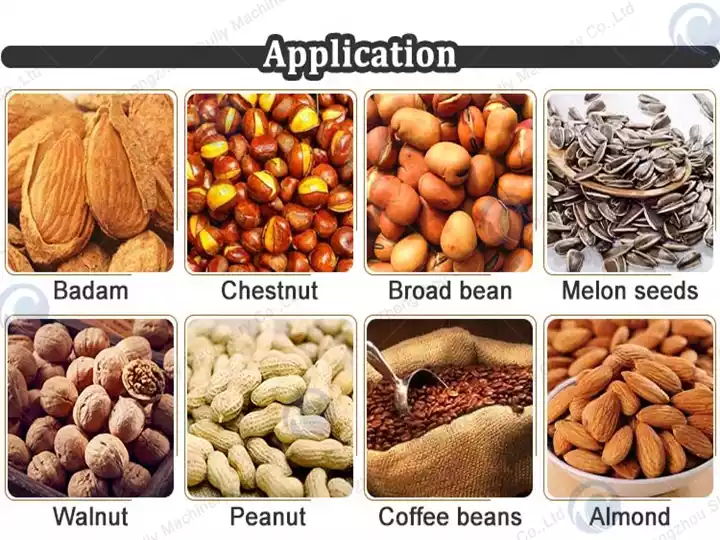

Applications de la machine de torréfaction continue des noix

Cette machine de torréfaction continue des noix est largement utilisée dans la transformation alimentaire et le séchage des sous-produits agricoles, notamment :

- Différents oléagineux : cacahuètes (en coque/décortiquées), graines de sésame, graines de tournesol, graines de citrouille, etc.

- Légumineuses : soja, mung, pois, fèves, etc.

- Noix de qualité supérieure : cajous, amandes, noix, pignons, noisettes, pistaches, etc.

- Piments séchés, fruits secs, légumes secs, et autres aliments assaisonnés.

- Autres produits nécessitant un séchage à basse température ou une cuisson à haute température.

Principales caractéristiques de la machine de torréfaction continue des noix

- Haute efficacité & économies d’énergie : la circulation d’air chaud combinée à des matériaux d’isolation de qualité réduit considérablement la consommation d’énergie et la perte de chaleur.

- Cuisson uniforme : l’air chaud à haute pression pénètre dans les couches de matière, assurant une distribution uniforme de la température pour une couleur et une texture croustillantes constantes.

- Contrôle intelligent de la température : plage large de 0-300°C pour répondre à divers besoins, du séchage à basse température à la cuisson à haute température.

- Haute automatisation : la vitesse du convoyeur et l’épaisseur de la matière sont réglables, permettant un contrôle par un seul opérateur, réduisant ainsi les coûts de main-d’œuvre.

- Sécurité & hygiène : toutes les surfaces en contact avec la matière utilisent de l’acier inoxydable de qualité alimentaire, conforme aux normes internationales d’exportation.

- Refroidissement intégré : système de refroidissement automatique monté à l’arrière pour éviter la surcuisson et améliorer la stabilité du produit.

- Compact & facile d’entretien : une conception structurelle rationnelle minimise l’empreinte tout en facilitant l’utilisation, le nettoyage et la maintenance.

Affichage structurel du torréfacteur automatique de noix

- Dispositif de levage : élève automatiquement les matériaux jusqu’à l’entrée d’alimentation, réduisant la main-d’œuvre.

- Système de convoyeur à plaques à chaîne : offre diverses options de plaques pour assurer une distribution uniforme de la matière et un transport stable.

- Panneau de contrôle électrique : doté d’un système de contrôle de température indépendant avec des températures réglables séparément pour les zones supérieure et inférieure pour une opération simple et précise.

- Unité de distribution de matière : fournit un stockage temporaire pour maintenir la continuité et la cohérence de la cuisson.

- Porte d’inspection : permet de surveiller en temps réel le processus de cuisson pour assurer la qualité.

Principe de fonctionnement du torréfacteur de cacahuètes continu

- Alimentation et convoyage des matériaux : les opérateurs versent les matériaux dans la trémie, qui sont automatiquement transportés par un élévateur jusqu’au système de cuisson à plaques. Les matériaux sont répartis uniformément sur les plaques.

- Chauffage par zone : les zones supérieure et inférieure de la chambre de cuisson disposent de systèmes de chauffage indépendants, permettant un réglage précis de la température selon les besoins.

- Cuisson à haute température : l’air chaud à haute pression pénètre uniformément dans la couche de matière, terminant la cuisson en environ 20 minutes pour assurer une couleur et une texture croustillantes constantes.

- Optimisation de l’efficacité énergétique : des brûleurs indépendants pour les zones supérieure et inférieure servent de sauvegardes mutuelles, assurant un fonctionnement continu même si une zone tombe en panne.

- Processus de refroidissement : après la cuisson, les matériaux entrent dans la zone de refroidissement pendant environ 10 minutes pour éviter la surchauffe et maintenir la qualité.

- Équipements auxiliaires optionnels : un alimentateur vibrant peut être ajouté à l’entrée d’alimentation, et un collecteur vibrant à la sortie pour améliorer la productivité et le niveau d’automatisation.

Paramètres techniques du torréfacteur continu

| Sortir | Puissance de chauffage | Transmission pouvoir | Tension | Dimensions | Chauffage méthode |

| environ 2000kg/h | 450kw | 32,5kw | 380 V 50 Hz 3 phases | environ 15000*3250*2550mm | chauffage électrique |

Que vous soyez une entreprise de traitement des noix, un fabricant alimentaire ou une boulangerie cherchant à améliorer la productivité et la qualité de vos produits, nos machines de torréfaction continue des noix offrent une expérience de production très efficace, économe en énergie et stable.

De plus, nous proposons d’autres types de torréfacteurs à tambour pour vous permettre de choisir. Nous fournissons des solutions personnalisées adaptées aux caractéristiques de votre matière et à vos besoins de production, vous aidant à atteindre une production automatisée et des résultats de cuisson de haute qualité. Contactez-nous dès aujourd’hui pour des solutions d’équipement et des prix !