The high-temperature sterilization pot is sterilization equipment. Since the sterilized food can be transported and stored at normal temperature, the cost in the circulation field is greatly reduced. In addition, sterilized food has a longer shelf life and can expand sales with the help of seasonal and regional differences, so as to obtain higher benefits.

High-temperature sterilization pot application market:

The high-temperature sterilization pot is suitable for the sterilization of all packaged items. According to the different packaging, the application market of high-temperature sterilization pot can be divided into:

- Plastic bottle containers: PP bottles, HDPE bottles, etc. For example, protein beverages that require high-temperature sterilization, such as milk, soy milk, almond milk, coconut milk, peanut milk, walnut milk, etc.

- Soft bag packaging: tin foil bag, vacuum bag, transparent bag, high-temperature cooking bag, etc. For example ham sausage, vacuum-packed chicken legs, etc.

- Tin cans, glass cans and so on: such as canned meat, canned fish, canned vegetables, canned fruits, and various seasoning cans.

Classification of high-temperature sterilization pot:

- According to the structure of the sterilization pot, it can be divided into vertical sterilization pot, horizontal sterilization pot, single tank sterilization pot, upper and lower tank sterilization pot, double pot parallel sterilization pot, and three pot parallel sterilization pot.

- According to the way of sterilization: divided into water bath sterilization, spray sterilization, and steam sterilization. Spraying sterilization can be divided into top spraying, side spraying, and omnidirectional spraying.

- It can be divided into automatic control sterilizing pot, computer semi-automatic control sterilizing pot and manual control sterilizing pot,according to the control mode.

Generally speaking, the water bath sterilizing pot uses the upper and lower pots to sterilize, the size of the upper pot and the lower pot is the same. Spray sterilizing pot is usually small on top and big on the bottom. Steam sterilizing pot does not need water circulation, so it usually uses a single tank sterilizing, requiring a steam generator.

Structure of high-temperature sterilization pot and sterilizing process:

The high-temperature sterilization pot is mainly composed of pot body, pipeline, hot water tank, cold water tank, heat exchanger, PLC control system and related accessories.

Sterilizing process:

Water preheating (heating for about half an hour) – after reaching the specified temperature, heat preservation and sterilization (holding for about half an hour) – cooling water intake (at this time, the first sterilization process has been completed, generally about 70 minutes can complete the whole sterilization process) – heating again (half an hour) – secondary sterilization by heat preservation( Sterilization temperature 121 degrees, maximum 180 degrees, high temperature, and pressure) – cooling – taking out materials

Advantages of different sterilization methods:

- Hot water circulating sterilization: When sterilizing, all the food in the pot is immersed in hot water. This method has uniform heat distribution and the best sterilization effect.

- Steam-type sterilization: After the food is put into the pot, it is not added with water first, but directly into the steam to heat up. Since the air in the pot will appear cold during the sterilization process, the heat distribution in this way is not the most uniform.

- Water-based sterilization: This method uses a nozzle or sprays pipe to spray hot water onto the food. The sterilizing process is carried out in a nozzle inside the sterilizing pot to spray a mist-like wave-shaped hot water to the surface of the food so that the temperature is uniform and there is no dead angle. Moreover, the temperature rise and the cooling rate are rapid, and the products in the pot can be sterilized comprehensively, quickly and stably. Particularly suitable for sterilization of soft packaged foods.

- Water-vapor mixed sterilization: This method was introduced by France. It combines steam and water spraying ingeniously. A small amount of water is added to the pot to meet the need for circulating spraying. Steam enters the pot directly and realizes short-term, high-efficiency, energy-saving and environmental protection. This machine is suitable for sterilization of special products.

Characteristics of sterilization pot:

- Can quickly sterilize in a short time.

- Saving energy. The water circulation inside the machine saves not only water resources but also heating consumption.

- Uniform water exchange mode, uniform temperature, no dead angle.

- The temperature inside the sterilization tank is always stable in all stages of the sterilization process, ensuring the pass rate of the F value.

- Fully automatic control system. Low noise, creating a quiet and comfortable working environment.

Three-pot parallel sterilization pot pipeline and motor - 100 sterilization formulas can be stored in the computer for selection.

- An analog temperature control system that can set up a multi-stage heating mechanism.

- Water in spray sterilizer sprays from different angles. Steam, air and water mix and convection to form perfect temperature distribution.

- The sterilizing pot is equipped with four movable temperature sensor probes, which can monitor F value of the food center, heat distribution in the sterilizing pot and heat penetration (the time when the temperature reaches the food geometry center from the food surface) at any time.

- Perfect pressure control, the pressure of the whole production process is constantly adjusted to adapt to changes in the internal pressure of product packaging, especially for gas-containing packaging products.

Technical parameters of sterilizing pot:

Because the technical parameters of different sterilizing pots are completely different. Our company has dozens of different types of sterilizing pots, technical parameters can not be listed for your reference. Here, take the single pot spray sterilizing pot as an example, to introduce to you:

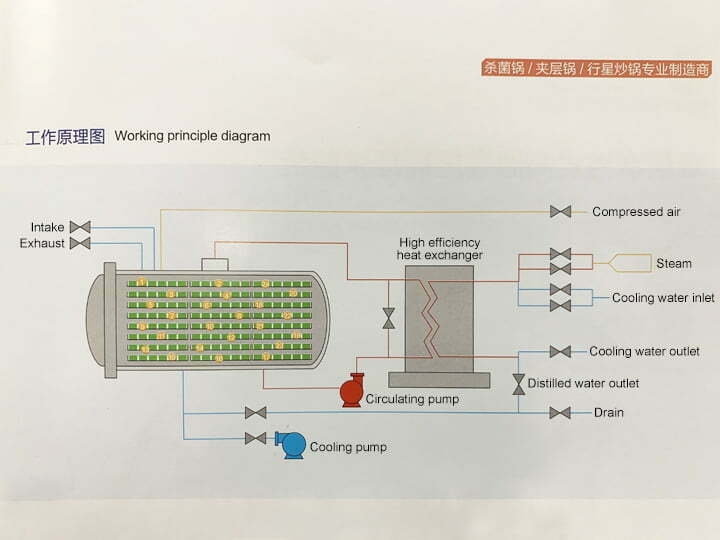

Working principle diagram:

Table of parameters:

| Tube length(mm) | 2400 | 2400 | 3200 | 3600 | 4000 |

| Total length(mm) | 3900 | 4400 | 5100 | 5500 | 5900 |

| Weight(mm) | 1500 | 1600 | |||

| High(mm) | 1700 | 1900 | |||

| Capacity(m³) | 2.2 | 3.2 | 4 | 4.6 | 4.9 |

| Food basket(个) | 3 | 3 | 4 | 4 | 5 |

| Gas consumption(kg/batach) | 95 | 130 | 185 | 210 | 230 |

| Power(kw) | 6.5 | 12 | |||

| Power consumption(kw/h) | 5.5 | 9 | |||

| Design temperature | 145℃ | ||||

| Experimental Pressure/Design Pressure | 0.44Mpa / 0.35Mpa | ||||

(The above parameters are for reference only.)