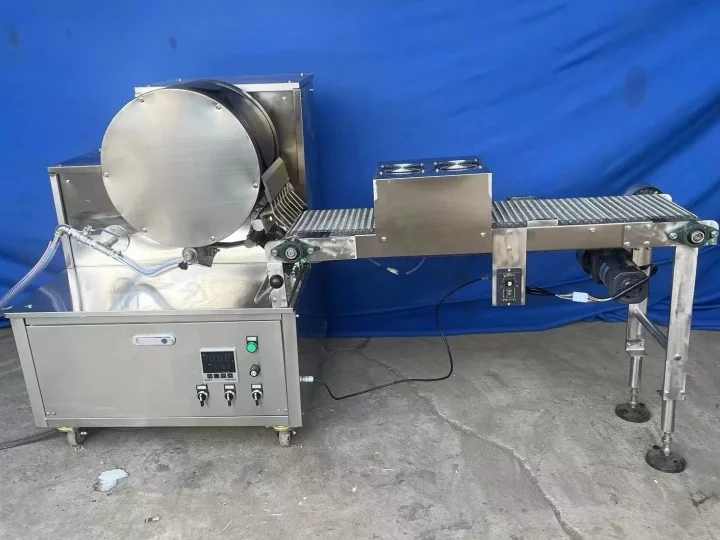

春巻きの皮製造機は、四角または丸い春巻きの皮を製造できる、高効率で多機能な食品加工装置です。フレンチクレープ、卵パンケーキ、北京ダックパンケーキ、その他の薄いパンケーキ風食品の製造にも使用できます。

約3人分の手作業を代替できるだけでなく、簡単な操作、高い生産量、低いエネルギー消費といった利点も備えています。食堂、食品加工工場、屋台などの場所で広く使用されています。

当社の春巻きの皮製造機は、コスタリカ、フィリピン、チリ、英国、ニューカレドニア、米国、リビアなど、複数の国と地域に輸出されており、顧客から広く称賛されています。

春巻き包装機の適用範囲

この春巻きの皮製造機は、春巻きの皮だけでなく、インジェラ、ローストダックパンケーキ、クレープ、卵ラップ、カレーラップ、クレープ、その他の薄いパンケーキも製造できるため、食品工場、レストラン、ファストフードレストラン、その他のビジネスシーンでの使用に適しています。

春巻きの皮製造機の利点

競合他社の機械と比較して、当社の春巻きの皮製造機には以下の利点があります。

- 操作が簡単:タッチスクリーン制御を搭載しており、学習と使用が容易です。

- 高品質な完成品:生地シートは損傷しにくく、包装や保管が容易です。

- 高い生産能力:複数の生産能力モデルが利用可能で、生産範囲は毎時500〜7000枚です。

- 高い調整性:生地シートの厚さと温度は、要件に応じて調整できます。

- 安全で衛生的:機械全体が食品グレードの304ステンレス鋼で作られており、FDA基準に準拠しており、清掃が容易で耐久性があります。

- エネルギー効率が高く高性能:可変周波数速度制御を利用して、ベーキング速度と製品品質を確保します。ワンステップ成形により廃棄物を削減します。

春巻きの皮製造機の技術パラメータ

異なる生産能力に応じて、4 台の春巻き皮製造機を販売しています。最小の機械では 500 個/h を生産できます。そして最大の春巻きシート製造機は最大7000個/hを生産できます。当社の機械が顧客のさまざまなニーズを満たすことができることがわかります。ご不明な点がございましたら、お気軽にお問い合わせください。

| モデル | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| 直径 加熱シリンダーの | 360mm | 500mm | 800mm | 1200mm |

| 機械のサイズ | 4.3*0.8*1.35メートル | 4.7*0.95*1.58メートル | 5.2*1*1.5メートル | 6.2*1.15*2メートル |

| 電力 | 6.0KW またはガス | 13.2KW またはガス | 38kw または ガス | 59kw または ガス |

| ホスト電源 | 0.75KW | TZ-3620と同じ | 0.75KW | 0.75KW |

| パワーカッター | 0.55KW | TZ-3620と同じ | 0.55KW | 0.55KW |

| ベルトパワー | 0.18kw | 0.55KW | TZ-5029と同じ | 0.55KW |

| N.W. | 320kg | 800kg | 1000kg | 1200kg |

| シートサイズ(最大) | 180mm丸 | 280mm丸 | 430mm丸 | 500mm丸 |

| 200mm長方形 | 290mm長方形 | 450mm長方形 | 520mm長方形 | |

| シートの厚さ | 0.3~1.0mm | TZ-3620と同じ | 0.3~1.0mm | 0.3~1.0mm |

| 生産能力 | 500-1000個/時間 | 1000-1600個/時間 | 3500個/時間 | 4500-7000p/h |

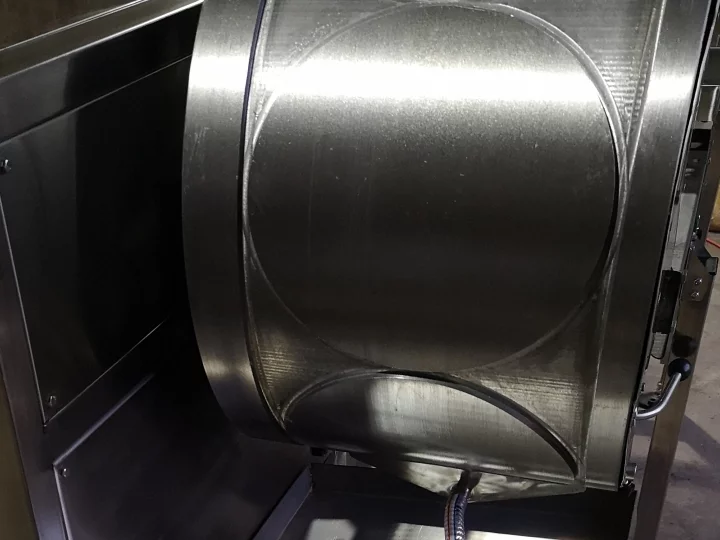

春巻きの皮製造機の構成部品

フレーム、空気圧コンポーネント、電気コンポーネント、加熱コンポーネント、成形研磨材、および冷却コンベア ベルトは、春巻き包装機の主要コンポーネントです。

春巻き包装機はどのように動作するのですか?

生地の準備:まず、春巻きの皮を作るのに必要な生地を準備します。手作業または生地ミキサー/バッターミキサーを使用して自動で準備し、生地が滑らかで均一であることを確認します。

装置の予熱:ベーキングホイールを約160℃に加熱し、皮を焼くのに適切な温度にします。

生地の塗布:バッターポンプを作動させて、生地をノズルに供給します。クラッチレバーを制御して、生地がベーキングホイールの湾曲した表面に均一に分布するようにします。

皮の収集:ベーキングホイールが270°~300°回転した後、生地が固まり、ベーキングホイールから自動的に分離され、丸いまたは四角い春巻きの皮が製造されます。

加熱方法の違いにより、機械は電気加熱、ガス加熱、電磁加熱の3つのカテゴリに分類できます。

さらに、この春巻きの皮製造機は、異なる加熱要件に応じて異なる加熱温度と時間を設定できます。また、加工ニーズに応じて異なるタイプを変更して、さまざまな厚さとサイズのパンケーキを作成することもできます。

機械使用上の注意

- 加熱シリンダーは、約70℃から80℃の温度で予熱する必要があります。加熱シリンダーの表面に少量の食用油を塗布する必要があります。

- ノズル両側のつまみを加熱シリンダーと平行になるように調整してください。調整後、生産を開始できます。

- 初期生産では速度と温度を少し下げます。生産が正常に実行されている場合、機械の速度と温度は徐々に上昇します。

- この機械を設置するときは、しっかりとした滑らかな地面を選択する必要があります。

- 本機を設置する際は、加熱シリンダーが軸線と平行になるように設置してください。また、機械の底部は完全に安定している必要があります。

- 生産終了後は、機械をきれいな水で洗浄する必要があります。

- 機械を使用する前にアース線を接続する必要があります。

- 使用中は加熱シリンダーに触れないでください。

トラブルシューティング方法

- 起動できない:電源、スイッチ、ワイヤー接続を確認し、正常に機能していることを確認します。

- 突然のシャットダウン:インバーターボタンを押すか、電源を再起動してみてください。それでも解決しない場合は、インバーターを交換してください。

- 本体の速度が調整されない:速度調整ボタンを確認または交換してください。

- コンベアベルトの速度が調整されない:伝達機構とモーターの損傷を確認してください。

- サーキットブレーカーがトリップする:加熱プレート、配線、銅スリップリングの漏電を確認してください。

- 加熱されない、または断続的な加熱:漏電制御メーターまたは熱電対を確認または交換してください。

ビデオ紹介:製造 春巻

この動画ではおいしい春巻きの作り方を学ぶことができます。

春巻きの皮製造機に関するよくある質問

春巻きの皮製造機は304ステンレス鋼でできていますか?

食品に接触するすべての部品は304ステンレス鋼です。研磨材は合金鋳鉄、一部は201ステンレス鋼です。そのため、この機械は長寿命です。

パンの厚みの調整範囲はどのくらいですか?

0.3~1.2mm。

パンの直径はどれくらいですか?

10〜60センチメートル。

生地ケーキを四角いものにすることはできますか?

はい。

この機械の電圧を変更できますか?

変圧器を設置することで電圧を変えることができます。より使いやすく、ガス加熱春巻き包装機を購入することもできます。