Spring roll wrapper making machine is mainly used to make spring roll wrappers, french pancakes, egg cake, peking duck pancake, etc. It can also make other kinds of sheet pasta.

Compared with traditional manual production, the spring roll wrapper making machine has the characteristics of simple operation, large output per unit time, and low energy consumption.

Because of these advantages, the spring roll wrapper machine is widely used in canteens, food processing plants, street snacks, and other places.

So far, our spring roll wrapper machines have been exported to Costa Rica, the Philippines, Chile, the United Kingdom, New Caledonia, the United States, and Libya.

Advantages of the spring roll wrapper making machine

Compared with peer machines, our spring roll sheet machine has the following advantages:

- Simple operation. The machine is operated using a touch screen and is easy to learn.

- High production efficiency. We have machines of different outputs for your choice, and the yield range is 500-7000 pcs/h.

- You can adjust the thickness of the pancake and the temperature of the machine according to your needs.

- The spring roll wrapper machine is made of high-quality 304 stainless steel, which meets the FDA standard. It is hygienic and easy to clean.

- The spring roll sheet making machine adopts frequency conversion speed regulation, which can ensure the speed and the cooking effect of the product.

- Because the products made by this machine are formed at one time, it will not cause waste. The final product is not easily damaged and is easy to pack.

Parameter of spring roll sheet machine

| Model | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| Dia. of heating Cylinder | 360mm | 500mm | 800mm | 1200mm |

| Size of machine | 4.3*0.8*1.35m | 4.7*0.95*1.58m | 5.2*1*1.5m | 6.2*1.15*2m |

| Electric Power | 6.0KW or gas | 13.2KW or gas | 38kw or gas | 59kw or gas |

| Host Power | 0.75KW | same as TZ-3620 | 0.75KW | 0.75KW |

| Power Cutter | 0.55KW | Same as TZ-3620 | 0.55KW | 0.55KW |

| Belt power | 0.18kw | 0.55KW | same as TZ-5029 | 0.55KW |

| N. W. | 320kg | 800kg | 1000Kg | 1200Kg |

| Size of the sheet ( Max.) | 180mm round | 280mm round | 430mm round | 500mm round |

| 200mm rectangular | 290mm rectangular | 450mm rectangular | 520mm rectangular | |

| The thickness of the sheet | 0.3-1.0mm | Same as TZ-3620 | 0.3-1.0mm | 0.3-1.0mm |

| Production capacity | 500-1000pcs/h | 1000-1600pcs/h | 3500pcs/h | 4500-7000p/h |

According to the different production capacity, we have four spring roll wrapper making machines for sale. The smallest machine can produce 500pcs/h. And the largest spring roll sheet making machine can produce up to 7000pcs/h. It can be seen that our machines can meet the different needs of customers. If you have any questions, please feel free to contact us.

Application range of spring roll wrapper machine

Spring roll wrapper machine can also make injera, roast duck pancakes, pancakes, egg wrappers, curry wrappers, crepes, and other wrappers. Therefore, this machine is suitable for food factories, restaurants, fast food restaurants, and other places.

Therefore, if you are looking for an Injera making machine, duck pancake machine, please feel free to contact us.

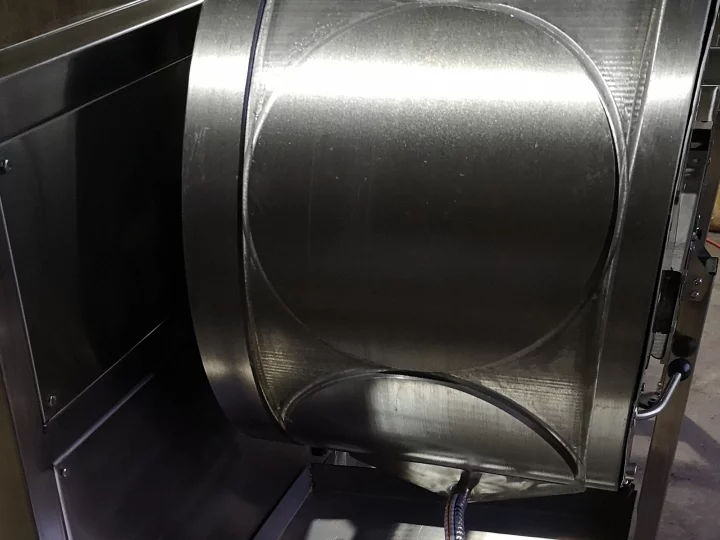

Components of spring roll wrapper making machine

Frame, pneumatic components, electrical components, heating components, shaped abrasives, and cooling conveyor belts are the main components of a spring roll wrapper making machine.

How does a spring roll wrapper machine work?

Make the batter. First, you need to prepare the batter for the spring roll wrapper. You can do it manually or use our batter machine to help you.

Preheat. Then heat the baking wheel to 160°C.

Spray the batter. Turn on the batter pump to send the batter to the nozzle. Operate the clutch lever to make the batter adhere to the arc surface of the baking wheel.

Collect the spring roll wrapper. After the baking wheel rotates 270-300 degrees, the batter will cooked and automatically separate from the baking wheel. Finally, you will get round or square spring roll wrappers.

According to the different heating methods, the machine can be divided into three categories: electric heating, gas heating, and electromagnetic heating.

In addition, this machine can set different heating temperatures and times according to different heating requirements. We can also change different types according to your processing needs to make pancakes of different thicknesses and sizes.

Precautions for using the machine

- The heating cylinder needs to be preheated at a temperature of about 70 ° C to 80 ° C. A small amount of edible oil should be applied to the surface of the heating cylinder.

- Adjust the knobs on both sides of the nozzle to make it parallel with the heating cylinder. After adjustment, the production can be started.

- In the initial production, the speed and temperature are lowered a little. When the production is running normally, the speed and temperature of the machine are gradually increased.

- When you are installing this machine, you should choose a firm and smooth ground.

- The heating cylinder must be parallel to the axis line when installing this machine. And the bottom of the machine needs to be completely stable.

- After the production is finished, the machine must be cleaned with clean water.

- The ground wire must be connected before the machine is used.

- Do not touch the heating cylinder during use.

Troubleshooting method

If the spring roll wrapper making machine does not start, check whether the power supply is connected correctly and whether the switches in each part are closed. And if not, check whether the wires, wireheads, or electrical appliances are connected and inserted properly.

The following situations occur after the installation and normal operation of machinery and equipment.

- If the spring roll wrapper making machine suddenly stops running, please press the red button or green button on the frequency converter. If it does not work properly, please turn off all the indicator lights on the power lamp converter. Then turn on the power supply to make the machine run. If it does not start, replace the frequency converter.

- The main engine can’t adjust speed: check whether the adjustable speed button is damaged, such as strengthening the top wire of the adjustable speed button, or replacing the adjustable speed button.

- Mesh belt can’t adjust speed: check whether the transmission is damaged and whether the motor is burnt down.

- Leakage circuit breaker trip: check whether the heating plate is leaking and whether the connecting wire and copper slip ring are leaking. If there is leakage, it is recommended to replace it.

- If the heating cylinder is not heated or intermittently heated, check whether the leakage control table or the hot spot couple is damaged.

Video introduction: making spring roll

In this video, you can learn how to make delicious spring rolls.

FAQ about the spring roll wrapper making machine

Is the spring roll wrapper maker machine made of 304 stainless steel?

All parts in contact with food are 304 stainless steel. Abrasives are alloy cast iron, part 201 stainless steel. So, this machine has a long service life.

What is the adjusting range of bread thickness?

0.3-1.2 mm.

What is the bread diameter?

10-60 cm.

Can dough cakes be made into square ones?

Yes.

Can you change the voltage of this machine?

The voltage can be changed by installing transformers. You can also choose to buy the gas heating spring roll wrapper making machine, more convenient to use.