In the realm of snack foods, potato chips hold a special place as a beloved crunchy treat enjoyed by people of all ages. If you’re considering venturing into the potato chips manufacturing business, one of the crucial aspects to understand is the cost involved in setting up and running a potato chips manufacturing plant.

This article will delve into various factors that influence the cost of a potato chips manufacturing plant, providing valuable insights for entrepreneurs and investors.

Initial Investment of the Potato Chips Manufacturing Plant

The first major cost consideration when setting up a potato chips manufacturing plant is the initial investment. This includes expenses such as purchasing or leasing a suitable facility, acquiring machinery and equipment, obtaining necessary licenses and permits, and setting up infrastructure for production and packaging. The cost of these elements can vary significantly based on factors like location, scale of operation, and the level of automation in the plant.

Potato Chips Making Machine Costs

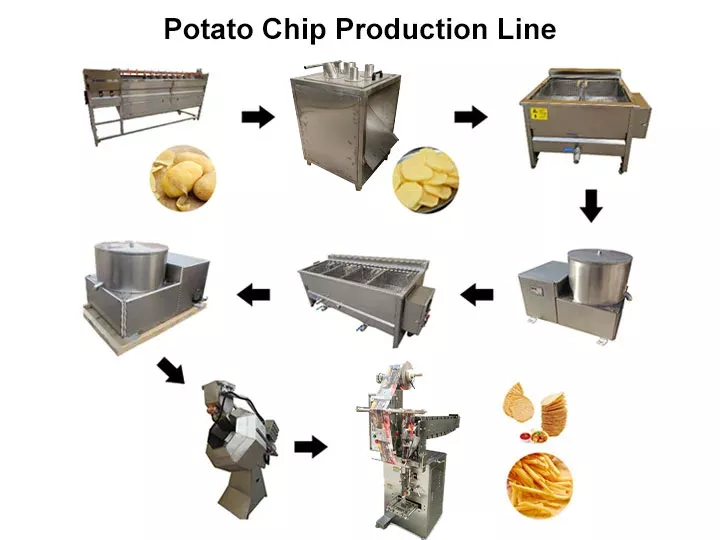

A significant portion of the initial investment goes into acquiring the potato chips making equipment and equipment required for potato chips production. This includes but is not limited to:

- Potato peeling and slicing machines

- Potato chip fryer equipment

- Oil filtration systems

- Potato chips seasoning machine

- Potato chip packaging machinery

The cost of these machines depends on factors such as capacity, brand, technology, and whether they are new or used. Investing in high-quality, efficient machinery is essential for ensuring consistent product quality and production efficiency.

Raw Material Expenses

Another crucial aspect of the cost structure is the expenses related to raw materials, primarily potatoes. The cost of potatoes can vary based on factors like seasonality, quality, and supply chain dynamics. Other raw materials such as cooking oil, seasoning ingredients, packaging materials, and utilities (electricity, water, gas) also contribute to the overall cost of production.

Labor Costs

Labor costs encompass wages for production workers, technicians, supervisors, and administrative staff involved in running the potato chips manufacturing plant. The level of automation in the plant can influence labor requirements and costs. Highly automated plants may require fewer workers but entail higher initial investment in machinery and technology.

Overhead and Miscellaneous Expenses

Apart from the direct costs mentioned above, there are various overhead and miscellaneous expenses to consider. These include maintenance and repair costs for machinery, marketing and advertising expenses, transportation and logistics costs, insurance, taxes, and contingencies for unforeseen expenses.

Total Cost Analysis

To determine the total cost of setting up and operating a potato chips manufacturing plant, a detailed cost analysis is essential. This involves estimating all the aforementioned costs, conducting market research to understand pricing dynamics, evaluating potential suppliers for raw materials and machinery, and forecasting revenue and profitability based on production capacity and market demand.