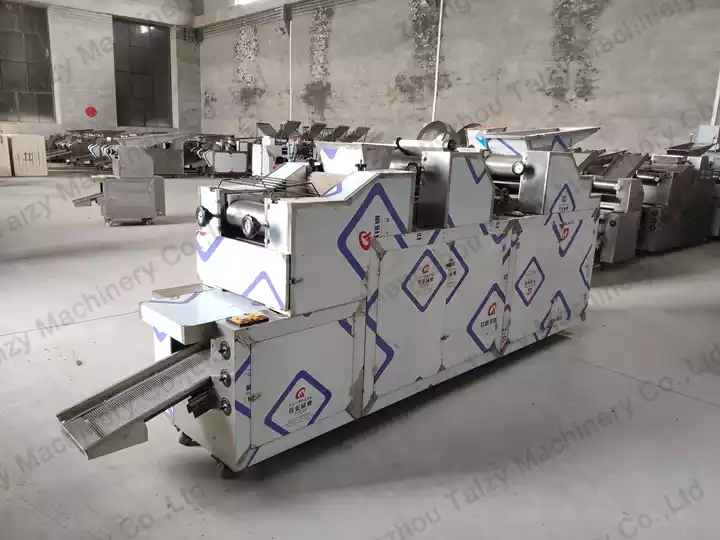

تم تصميم آلة تقطيع تشين تشين خصيصًا لمعالجة أنواع مختلفة من نودلز الوجبات الخفيفة، وقطع العجين بشكل فعال ومتسق إلى كتل أو شرائط ذات أشكال موحدة. من خلال طرق القطع الميكانيكية والموحدة، يعالج هذا الجهاز المشكلات المرتبطة بالقطع اليدوي — مثل انخفاض الكفاءة، وعدم التناسق في الأبعاد، والتحديات الصحية.

تتراوح قدرته الإنتاجية من 300 إلى 800 كجم في الساعة (اعتمادًا على تركيبة العجين ومواصفات القطع). يمكن تشغيله بواسطة مشغل واحد. مع ضمان مظهر منتج موحد، يعزز بشكل كبير كفاءة الإنتاج ومعايير سلامة الغذاء، مما يجعله مقبولًا على نطاق واسع في خطوط إنتاج الوجبات الخفيفة التجارية والصناعية.

ما هي الوجبات الخفيفة تشين تشين؟

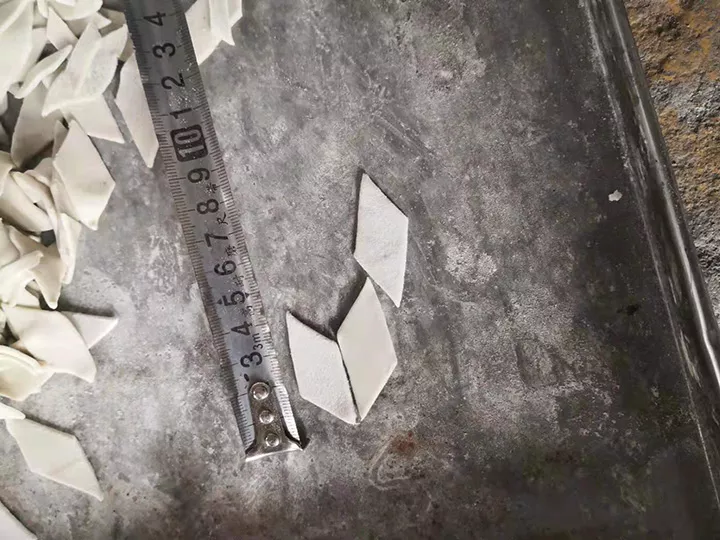

تشين تشين هو نوع من الوجبات الخفيفة المقلية التي تحظى بشعبية كبيرة في غرب أفريقيا، وخاصة في نيجيريا. عادةً ما تكون ثعابين تشين تشين مربعة الشكل، لكن بعض الأشخاص يصنعونها في أشكال أخرى، مثل المعين أو الشريط الطويل أو الدائري.

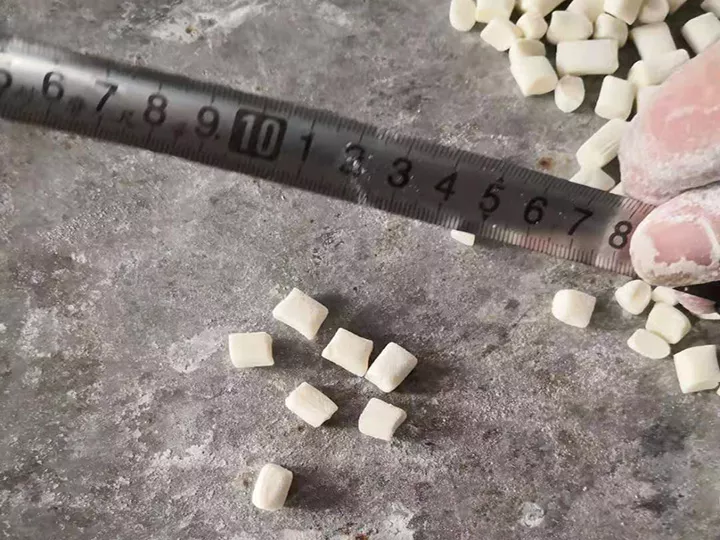

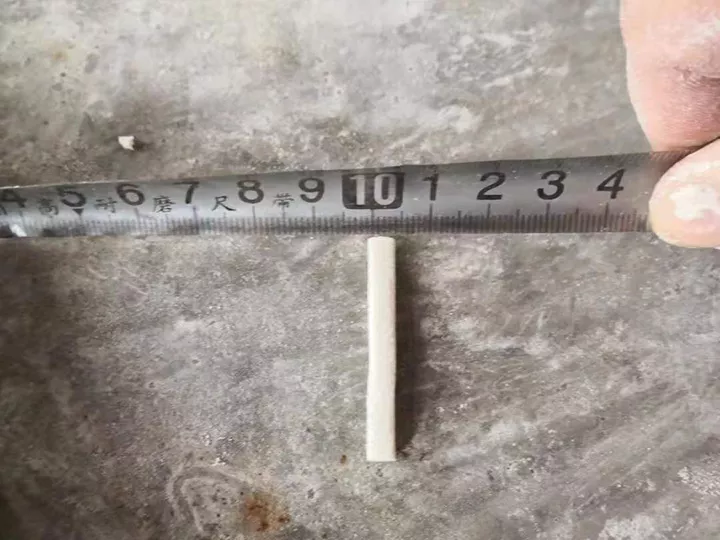

عادةً، يتطلب صنع وجبات تشين تشين الدقيق، السكر، الملح، الزبدة، البيض، الحليب، وزيت الخضروات. اخلط المكونات أعلاه معًا لصنع العجين، ثم قطع العجين إلى قطع طولها 2-3 سم، وسمكها حوالي 6 ملم. بعد ذلك، اسكب زيت الخضروات في القدر واتركه يغلي برفق. أضف العجين المقطع برفق إلى الزيت واقليه حتى يصبح ذهبي اللون.

أنواع آلات تقطيع تشين تشين

نحن نبيع آلات تقطيع تشين تشين نصف أوتوماتيكية وآلات تقطيع تشين تشين أوتوماتيكية. يمكن لكلتا الآلتين إنتاج تشين تشين بأشكال مكعبات، وألماس، وشرائط، وغيرها.

الفرق بين هذين القاطعين الكهربائيين لتشين تشين هو بشكل رئيسي الإنتاج، ودرجة الأتمتة، والسعر. المنتج النهائي والجودة متساويان. يمكن للعملاء اختيار الآلة المناسبة وفقًا لاحتياجاتهم.

تطبيقات آلة تقطيع تشين تشين

يمكن لهذا الجهاز قطع أوراق العجين إلى مربعات، وألماس، وشرائط، أو حبيبات صغيرة، لتلبية متطلبات السوق المختلفة وشكل المنتج مع مرونة قوية.

- إنتاج كميات كبيرة من وجبات تشين تشين

- التحضير المسبق للوجبات المقلية أو المخبوزة من العجين

- تقطيع ومعالجة نودلز الأرز، نودلز العسل ذات الثلاثة سكاكين، والنودلز على الطراز العرقي

- مصانع معالجة الطعام، خطوط إنتاج الوجبات الخفيفة، مصانع العجين المجمد

- مصدرو الطعام الأفريقي، المطابخ المركزية للمدارس والمؤسسات

ميزات آلة تقطيع تشين تشين

- قطع دقيق ومتسق: أبعاد وسمك موحد، مظهر جمالي، يسهل الإنتاج الموحد.

- كفاءة عالية وإنتاج كبير: يتيح التشغيل المستمر معالجة دفعات كبيرة من العجين بسرعة.

- توفير تكاليف العمالة: تشغيل بواسطة شخص واحد لإدخال العجين، بدلاً من القطع اليدوي المكثف.

- تصميم مقاوم للالتصاق: رش الدقيق تلقائيًا على الأجهزة في الأمام والخلف لمنع التصاق أوراق العجين معًا، مع كمية دقيق قابلة للتعديل.

- عملية بسيطة: ضبط سمك المنتج وأبعاده عبر المقابض للتكيف المرن مع منتجات مختلفة.

- نظيف وآمن: مناسب لبيئات معالجة الطعام، سهل التفكيك والتنظيف، ومتوافق مع معايير النظافة الغذائية.

مبدأ عمل آلة تقطيع تشين تشين

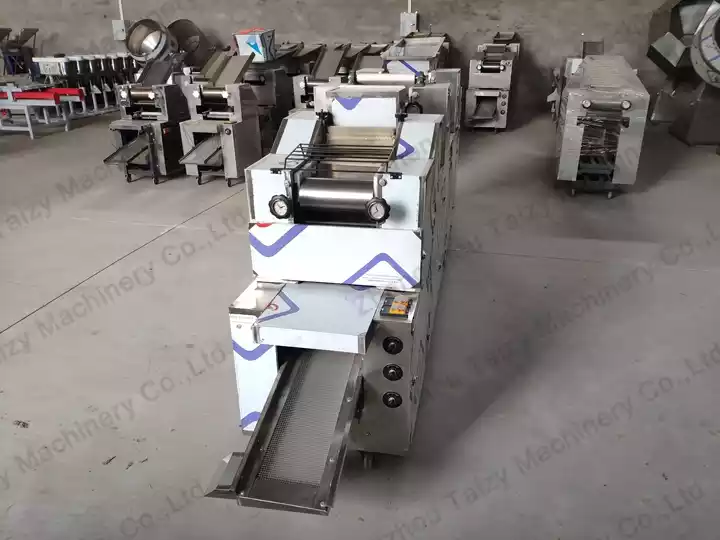

يستخدم قاطع كتلة تشين تشين طريقة معالجة مستمرة تجمع بين التدحرج والقطع:

- لف العجين المُعد إلى أوراق بسمك مناسب.

- بعد وضع أوراق العجين عند مدخل التغذية، ينقلها حزام ناقل إلى منطقة التدحرج.

- من خلال الضغط بواسطة بكرتين علويتين وسفليتين، يتم ضغط الأوراق إلى السمك المطلوب، ويمكن تعديله عن طريق تغيير فجوة البكرات.

- ثم تدخل الورقة المسطحة إلى آلية القطع، حيث تقوم الشفرات الدوارة بتنفيذ عملية القطع.

- اعتمادًا على تكوين الشفرة، يمكن قطع الورقة إلى مربعات، وألماس، وهلال، وشرائط، أو حبيبات صغيرة.

- يتم تفريغ قطع النودلز المشكّلة تلقائيًا للعمليات التالية من القلي أو التعبئة.

العملية بأكملها مستمرة ومستقرة، وتوفر كفاءة عالية في القطع لتلبية متطلبات الإنتاج الصناعي لوجبات تشين تشين.

معلمات آلة تقطيع تشين تشين

| يكتب | TZ-150 | TZ-1000 |

| قوة | 2.6 كيلو واط | 4.5 كيلو واط |

| سعة | 150 ~ 300 كجم / ساعة | 1000 كجم/ساعة |

| وزن | 280 كجم | 800 كجم |

| مقاس | 1500*560*1200 مللي متر | 3300*610*1500 مللي متر |

آلة تقطيع تشين تشين أكثر من مجرد جهاز قطع بسيط — إنها قطعة أساسية من معدات منتجي الطعام الذين يسعون لتحقيق جودة ثابتة، وكفاءة أعلى، وإنتاجية قابلة للتوسع من وجبات تشين تشين الخفيفة. من خلال أتمتة عملية القطع، يمكن للمصنعين تقليل الاعتماد على العمالة، وخفض تكاليف التشغيل، وتحقيق نتائج موحدة تلبي توقعات السوق المتزايدة.

من المطابخ التجارية الصغيرة إلى خطوط الإنتاج الصناعية الكبيرة، توفر آلة تقطيع تشين تشين الموثوقة حلاً عمليًا وفعالًا من حيث التكلفة. مع توفر نماذج متعددة لتلبية قدرات إنتاج مختلفة وميزانيات، فهي استثمار مرن يدعم النمو التجاري على المدى الطويل.