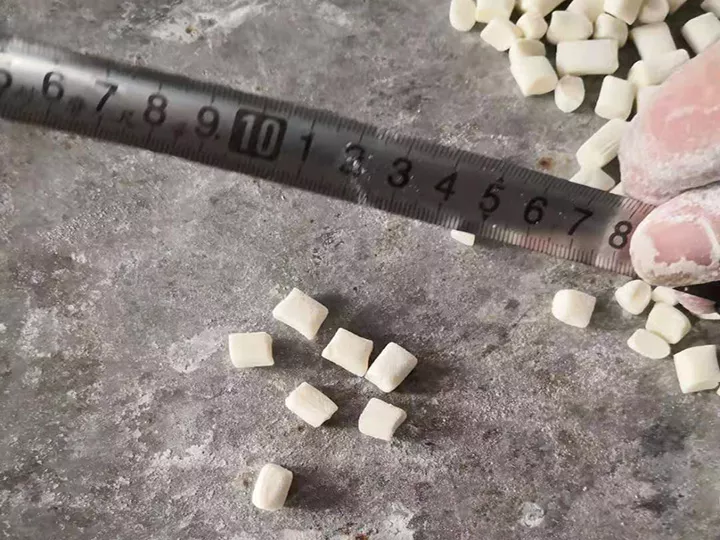

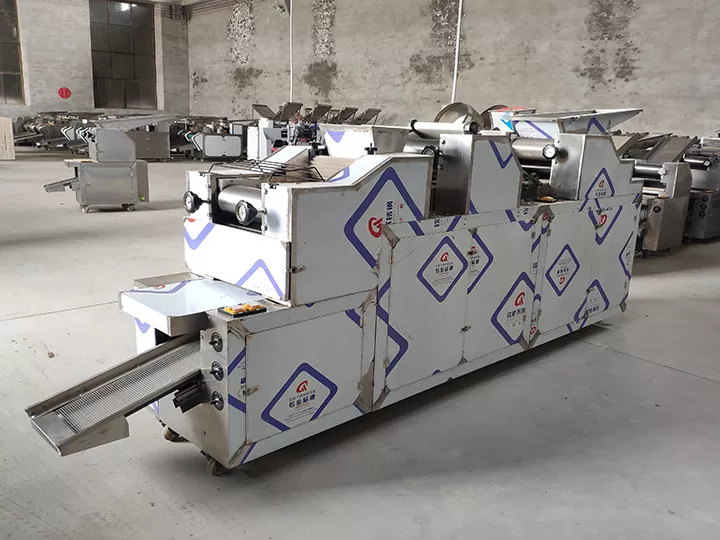

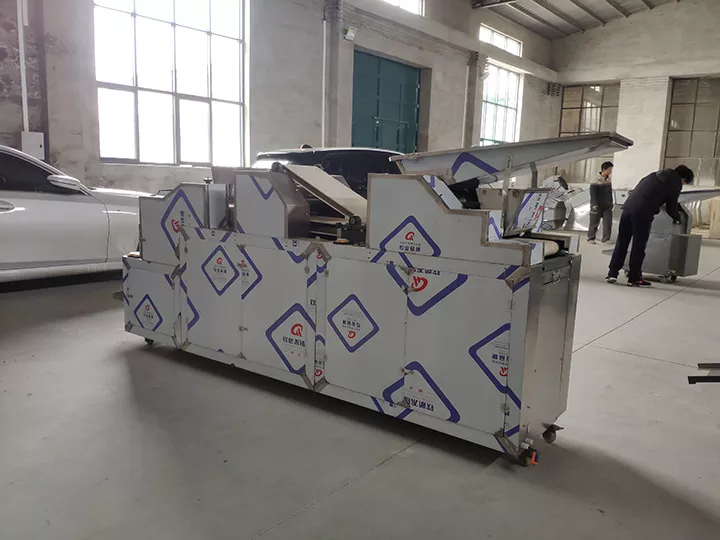

The automatic Chin Chin cutting machine is widely used in the processing of rice noodles, honey three knives, Chin Chin snacks, and other snacks. The machine can cut patches into diamond-shaped and square noodles, and can also be cut into long strips or small dice. The machine has high working efficiency, which effectively replaces manual cutting.

Working principle of the Chin Chin cutter

Put the dough sheet on the feed buckle, start the machine, and the dough will be transported between the rollers. Under the action of the conveyor belt and the rollers, the pressing process will be automatically completed to achieve the required processing thickness. The thickness can be achieved by adjusting the roller, and the user can adjust it according to the actual situation and requirements. The pressed dough is fed into the forming machine through a conveyor belt for cutting, which can be cut into squares, diamonds, moons, etc.

Types of chin chin cutter

At Taizy Food Machinery Factory, we have semi-automatic chin chin cutting machines and automatic chin chin cutter machines for sale. Both machines can produce chin chin in the shape of dice, diamonds, strips, etc. The difference between these two electric chin chin cutters is mainly the output, the degree of automation, and the price. The finished product and quality are the same. Customers can choose the right machine according to their needs.

Parameters of the Chin Chin cutting machine

| Type | TZ-150 | TZ-1000 |

| Power | 2.6kw | 4.5kw |

| Capacity | 150~300kg/h | 1000kg/h |

| Weight | 280kg | 800kg |

| Size | 1500*560*1200mm | 3300*610*1500mm |

These are the parameters of the two hot-selling chin chin cutting machines. Their output is 150 to 300kg/h and 1000kg/h, respectively. The power is 2.6kw and 4.5kw respectively.

Features of the Chin Chin cutting machine

- The machine is easy to operate, only one person is required to put the raw materials into the feed inlet, and the rest of the cutting work is done by the machine.

- There are two automatic flour-spreading devices at the front and back of the machine, which can prevent the noodles from sticking, and the amount of flour can be adjusted.

- The Chin Chin cutting machine has a large output, and high efficiency, which greatly saves labor costs and makes production costs lower.

- The size and thickness of the product are very uniform. There is a handle to rotate and adjust the size of the finished product.

What are Chin Chin snacks?

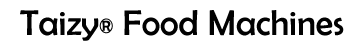

Chin Chin is a kind of fried snack that is very popular in Western Africa, especially in Nigeria. Usually, Chin Chin snakes are square, but some people make them into other shapes, such as rhombus, long strip, or round.

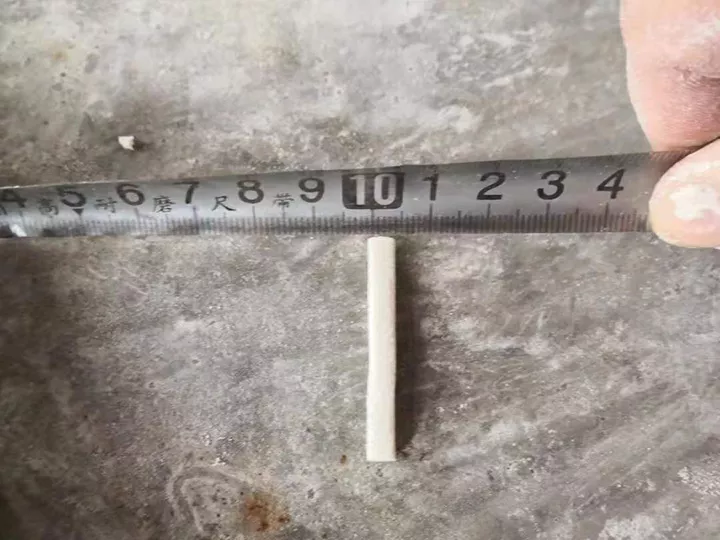

Usually, flour, sugar, salt, butter, egg, milk, and vegetable oil are needed to make Chin Chin snacks. Mix the above ingredients into a dough, and then cut the dough into pieces of 2 to 3 cm pieces, about 6 mm thick. Next, pour the vegetable oil into the pot and boil it, gently put the cut dough into the oil, and fry until golden brown.