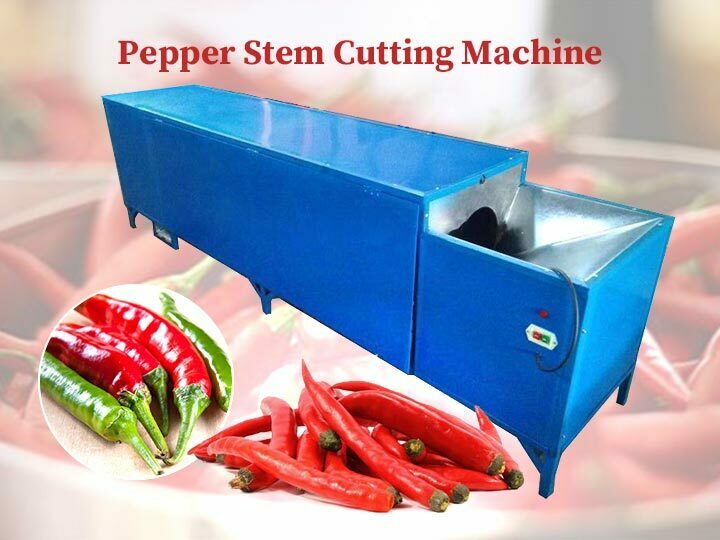

تستطيع ماكينة قطع سيقان الفلفل الأوتوماتيكية بالكامل لدينا إزالة السيقان أو الذيل للفلفل الطازج والفلفل المجفف والفلفل من أنواع وأحجام مختلفة بسرعة ودقة.

في مجال معالجة الفلفل، فإن إزالة السيبال يدويًا ليست فقط غير فعالة (حجم المعالجة اليومي المتوسط أقل من 50 كجم)، ولكنها أيضًا تسبب حروقًا ليد المشغل بسبب تحفيز الكابسيسين، مما أصبح نقطة ألم تقيد الترقية الصناعية.

تتطلب آلة قطع سيقان الفلفل هذه شخصًا واحدًا فقط للتشغيل لتحقيق معدل إزالة السيقان يزيد عن 95٪، ويمكن أن تصل سرعة المعالجة إلى 2000 كجم/ساعة، وهو ما يعادل 10-15 مرة من كفاءة العمل اليدوي.

المزايا الأساسية لآلة قطع سيقان الفلفل

- سكاكين دقيقة وتصميم ذكي للسقوط، الشق سلس ولا يوجد بقايا، مما يقلل بشكل كبير من الضرر على اللب.

- جسم الآلة مغلق بالكامل ومزود بفتحة تصريف غازات العادم لضمان عدم تسرب الغبار أثناء عملية القطع.

- تكنولوجيا الفرز التلقائي تحقق فصل فعال للمنتجات النهائية والمواد المهدرة لضمان جودة المعالجة اللاحقة.

- يمكن ضبط المسافة وزاوية القطع لشفرة السكين بسرعة، مما يجعلها مناسبة لمجموعة متنوعة من الأحجام والرطوبة للفلفل الحار الطازج والمجفف.

- إنتاج آلة قطع سيقان الفلفل الواحدة يزيد عن 5 مرات من المنتجات المماثلة في السوق، ويمكن أن يصل الإنتاج اليومي إلى عدة أطنان، مما يقصر بشكل واضح من دورة المعالجة.

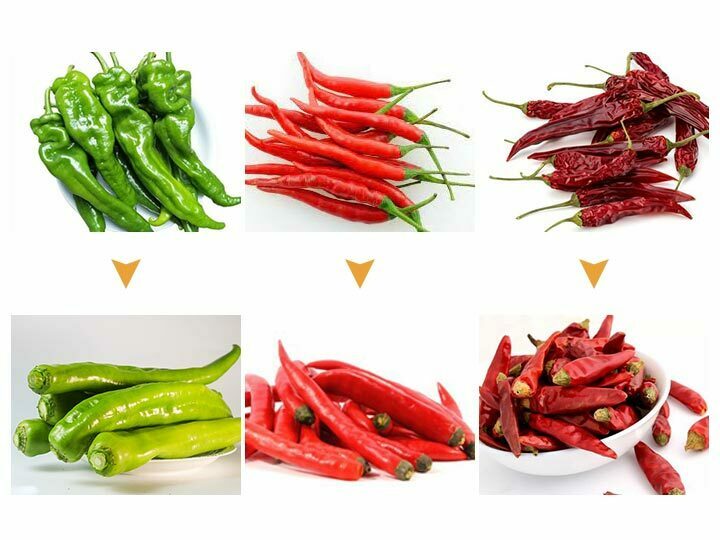

نطاق وتطبيقات آلة إزالة سيقان الفلفل الحار

تدعم آلة قطع سيقان الفلفل قطعًا دقيقًا لأحجام مختلفة من الفلفل من خلال تصميم معياري (نطاق ضبط من 1-10 سم). يمكن تكييفها مع الأصناف الرئيسية في السوق مثل فلفل تشاوتيان، فلفل الدخن، فلفل الخط، الفلفل الحلو، فلفل سان البري، وما إلى ذلك. تُستخدم الآلة على نطاق واسع في السيناريوهات العملية التالية:

- المزارع الصغيرة والمتوسطة والكبيرة، التعاونيات الزراعية: الفرز الأولي وإزالة السيبال من الفلفل الطازج والمجفف، وتقليل كثافة العمل اليدوي.

- مصانع المعالجة العميقة للفلفل (مسحوق الفلفل الحار، زيت الفلفل الحار، إنتاج الصلصة): خط تجميع آلي في واجهة إزالة السيقان لضمان جودة المنتج وتناسق عمليات التجفيف والطحن والاستخراج وغيرها من العمليات في الأسفل.

- مطبخ مركزي، خط إنتاج خضروات مسبقة الصنع: توفير المواد الخام من الفلفل الحار المقشر والمنظف لسلاسل المطاعم أو المواد الغذائية المجمدة لضمان معايير سلامة الغذاء والنظافة.

- سوق الجملة، تخزين سلسلة التبريد: فرز ومعالجة كميات كبيرة من الفلفل الطازج/المجفف لتوفير مصادر مؤهلة للموزعين أو المصدرين.

مبدأ عمل آلة إزالة سيقان الفلفل الحار

- يتم تغذية الفلفل الحار بشكل موحد إلى صندوق التغذية يدويًا أو بواسطة ناقل، ويتم ترتيبها بشكل مرتب بواسطة جهاز الاهتزاز أو الأخدود الموجه.

- مدفوعًا بمحرك تحويل التردد، تدور أقراص السكين المزدوجة بسرعة عالية ضد بعضها البعض، وتلف شفرات السكين بدقة جذور سيقان الفلفل لتحقيق القطع السريع.

- تُوجه السيقان المقطوعة إلى منفذ الجمع، بينما تنزلق الثمار الكاملة إلى منفذ التفريغ بفعل الجاذبية، وتستمر العملية بأكملها بشكل مستمر.

- بعد إزالة السيقان، تكون الفلفل نظيفة ومرتبة، مما يسهل عملية التجفيف الهوائي أو الخبز أو التعبئة، ويحافظ على اللون الزاهي والنكهة النقية للثمار.

معلمات آلة إزالة سيقان الفلفل

| يكتب | الجهد االكهربى | قوة | مقاس | وزن | مادة | سعة الفلفل الحار الطازج | سعة الفلفل الحار الجاف |

| TZ-50-2A | 220 فولت، 50 هرتز، مرحلة واحدة | 3 كيلو واط | 2860*590*1360 ملم | 238 كجم | الصلب الكربوني | 250 كجم/ساعة | 120 كجم/ساعة |

| TZ-50-2S | 220 فولت، 50 هرتز، مرحلة واحدة | 3 كيلو واط | 2860*590*1360 مللي متر | 252 كجم | 304 الفولاذ المقاوم للصدأ | 250 كجم/ساعة | 120 كجم/ساعة |

| TZ-50-2ALT | 220 فولت، 50 هرتز، مرحلة واحدة | 3 كيلو واط | 3860*590*1360 مللي متر | 357 كجم | الصلب الكربوني | 330 كجم/ساعة | 180 كجم/ساعة |

| TZ-50-2SLT | 220 فولت، 50 هرتز، مرحلة واحدة | 3 كيلو واط | 3860*590*1360 مللي متر | 362 كجم | 304 الفولاذ المقاوم للصدأ | 330 كجم/ساعة | 180 كجم/ساعة |

| TZ-50-2ABIGS | 220 فولت، 50 هرتز، مرحلة واحدة | 4.4 كيلو واط | 2860*1100*1500 مللي متر | 470 كجم | الصلب الكربوني | 500 كجم/ساعة | 250 كجم/ساعة |

| TZ-50-2SBIGS | 220 فولت، 50 هرتز، مرحلة واحدة | 4.4 كيلو واط | 2860*1100*1500 مللي متر | 482 كجم | 304 الفولاذ المقاوم للصدأ | 500 كجم/ساعة | 250 كجم/ساعة |

| TZ-70W-2ATL | 220 فولت، 50 هرتز، مرحلة واحدة | 4.4 كيلو واط | 3860*680*1600 مللي متر | 476 كجم | الصلب الكربوني | 400 كجم/ساعة | 220 كجم/ساعة |

| TZ-70W-2ANF | 220 فولت، 50 هرتز، مرحلة واحدة | 4.4 كيلو واط | 4860*680*1650 مللي متر | 550 كجم | الصلب الكربوني | 700 كجم/ساعة | 350 كجم/ساعة |

| TZ-50-1ATL | 220 فولت، 50 هرتز، مرحلة واحدة | 1.5 كيلو واط | 3860*600*830 مللي متر | 143 كجم | الصلب الكربوني | 180 كجم/ساعة | 90 كجم/ساعة |

| TZ-50-1A | 220 فولت، 50 هرتز، مرحلة واحدة | 1.5 كيلو واط | 2860*590*850 مللي متر | 95 كجم | الصلب الكربوني | 120 كجم/ساعة | 60 كجم/ساعة |

| TZ-200-2ABTL | 380 فولت، 50 هرتز، 3 مراحل | 6 كيلو واط | 6200*860*2200 مللي متر | 1370 كجم | الصلب الكربوني | 900 كجم/ساعة | 500 كجم/ساعة |

| TZ-200-2ABIGGERS | 380 فولت، 50 هرتز، 3 مراحل | 8 كيلو واط | 6800*1100*2700 مللي متر | 1575 كجم | الصلب الكربوني | 1000 كجم/ساعة | 800 كجم/ساعة |

| TZ-300-2ABIGGERS | 380 فولت، 50 هرتز، 3 مراحل | 8 كيلو واط | 8200*1100*2800 مللي متر | 2100 كجم | الصلب الكربوني | 2000 كجم/ساعة | 1000 كجم/ساعة |

بالإضافة إلى ذلك، شركتنا مجهزة بـ آلة غسل الخضار و آلة تقطيع الخضار لمساعدتك في معالجة الفلفل الخاص بك.

اتصل بفريقنا المحترف الآن للحصول على تجربة مجانية وحلول مخصصة! نحن نقدم أيضًا ضمان ما بعد البيع. لا تتردد في الاتصال بنا لمزيد من المعلومات!