The dough maker is one of the essential machinery for making pasta foods. Its main purpose is to mix water and flour into the dough. With the rotation of the mixer inside the machine, the flour and water first form small particles in the mixing bucket. And then with folding, pressing, stretching, kneading and another process, the dough is finally obtained. This machine can say goodbye to the traditional hand-made dough and easily solve the problem of high labor costs.

Application place for dough maker:

There are many uses for dough mixer, and almost all processes that require agitation can be done with this machine. This machine can be used to stir butter, cheese, fresh milk, eggs, etc. It can also be seasoned with this machine, such as mixing fruit puree, noodles, ice-sand, and cold dishes. In the process of making Shaqima and peanut brittle, it can mix the raw material and the syrup. All in all, it is a good helper in pasta processing factories, bakeries, and other places.

How does the flour mixing machine work?

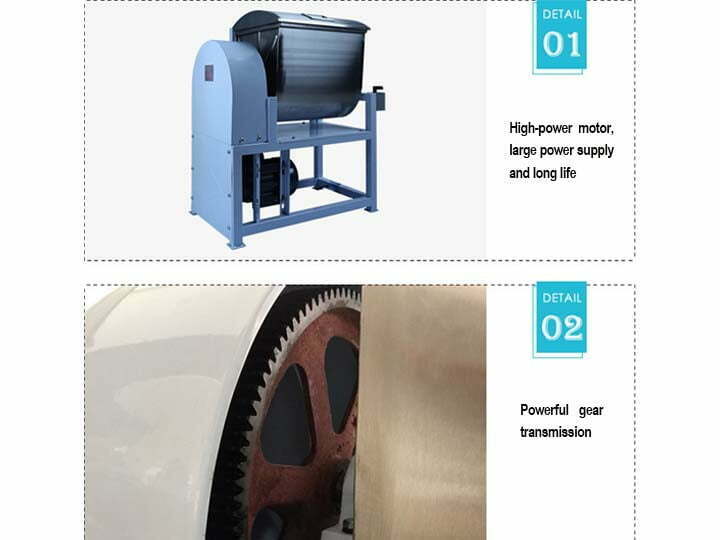

The Major Components of this machine: mixing barrel, mixer, transmission device, motor, machine base, control panel, etc.

The shapes of agitators in different machines are different. Generally, there are spiral shape mixer and knife shape mixer (consisting of a stirring shaft and stirring roller). When the dough maker is running, a certain proportion of flour and water is put into the hopper, and the transmission device will drive the mixer to turn continuously in the hopper. The flour and water in the cylinder are continuously pushed, pulled, smashed, pressed, fully stirred, and quickly mixed, so that the dry flour is uniformly hydrated, and the gluten is expanded to finally form a dough having a certain elasticity and flexibility.

Advantages of the dough maker:

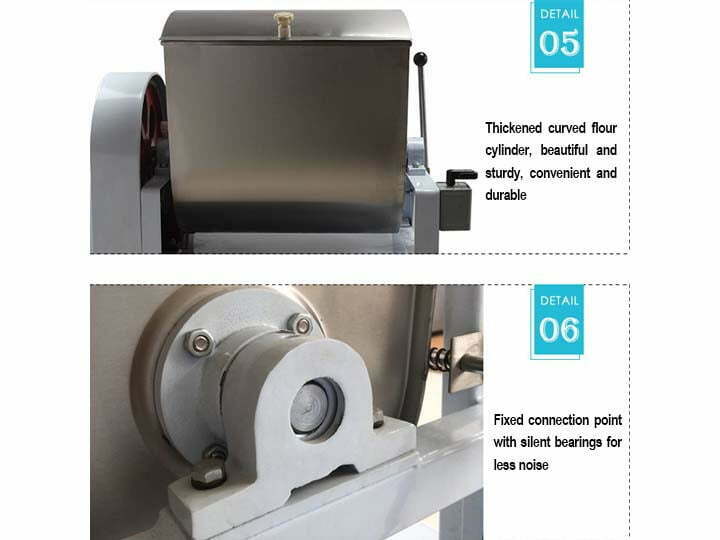

- The dough maker is made of stainless steel. Even if it is in contact with water for a long time, it is not easy to rust and corrosion.

- Two types of the mixer. The new design ensures that water and dough or other raw materials can be fully stirred. You can choose the two styles according to your own needs.

- The mixing barrel can be turned over. The barrel can turn 90 degrees automatically and take out the instant dough directly after it is made.

- The machine settings have forward and reverse rotation. The mixer inside the machine can be rotated forward or reversed. The two rotation modes can be easily adjusted so that the material can be more fully mixed. Get a soft, good-tasting dough.

- It is safer to use. There is a safety bolt on both sides of the machine, which can prevent the bucket from tilting when mixing the dough, and the bolt can be pulled out when taking the dough.

- All-copper wire motor. The motor is configured as a high-power copper wire motor with long service life and large power supply.

Main technical parameters of dough maker:

| Type | Output (kg) | Time required(min) | Voltage (v) | Power (kW) | Weight (kg) | Size

(mm) |

| 12.5 | 12.5 | 3-10 | 220/380 | 1.5 | 100 | 650*400*730 |

| 25 | 25 | 3-10 | 220/380 | 1.5 | 128 | 685*480*910 |

| 37.5 | 37.5 | 3-10 | 220/380 | 2.2 | 175 | 840*480*910 |

| 50 | 50 | 3-10 | 220 | 2.2 | 230 | 1070*570*1050 |

| 380 | 2.575 | 275 | ||||

| 75 | 75 | 3-10 | 380 | 3.75 | 475 | 1410*680*1250 |

| 100 | 100 | 3-10 | 380 | 3.75 | 490 | 1520*680*1250 |

| 150 | 150 | 3-10 | 380 | 6.25 | 700 | 1710*730*1400 |

Related production line: peanut brittle production line