ガーリ加工機(生産ライン)には、さまざまな機械が含まれています。機械の種類によって、自動キャッサバ粉生産ラインと半自動キャッサバ粉生産ラインの2種類があります。お客様のさまざまな要求に応えるため、当社はお客様があらゆる種類の機械を理解するお手伝いをします。また、お客様の実際の状況と要求に応じて、専用の生産ラインを設計することもできます。

ガーリ生産ラインはウェットプロセスを使用し、添加物は一切加えていません。全工程は、成熟した技術、先進的な設備、科学的な構成、合理的なプロセスを備えています。全工程は、洗浄・皮むき → 破砕 → 圧搾脱水 → 発酵 → 粉砕 → 撹拌/炒め → 選別です。

では、完全な Garri 処理マシンにはどのようなマシンが含まれているのでしょうか?

まず、発酵プロセスは自然条件下で行われるため、機械の助けは必要ありません。ガリ加工ラインにおいて全自動化を実現するには、ホイストは欠かせない機械の一つです。今回は洗浄と剥離の工程からスタートしますが、機械としては以下のようなものがあります。

- 洗浄剥離機

- キャッサバ破砕機

- プレス脱水機

- グラインダー

- 中華鍋/ジャケット付き鍋

- 三段ふるい機

ガリ加工機の各種機械のご紹介:

1.洗浄剥離機

洗浄と皮むきの2つの工程を組み合わせたガリ取り機です。洗浄の目的は、砂の除去、土の除去、皮むき、でんぷん灰の低減、そして次の工程の作業を円滑にすることです。洗浄は輸送と同時に行われるため、供給は均一でなければなりません。多すぎるとケージに隙間がなく、キャッサバが転がらず、皮をむいてきれいにするという目的を達成できません。少なすぎると生産が不十分です。 Garri 加工機の内部には、キャッサバをシャーシ内で押し込んで回転させるスパイラル メッシュ スクリーンがあり、キャッサバをあらゆる角度から洗浄します。シャーシ下部には7つのローラーがあり、それぞれのローラーに小さなスクレーパーが多数取り付けられています。盛り上がったスクレーパーは、回転中にキャッサバのスカーフスキンを取り除くことができます。

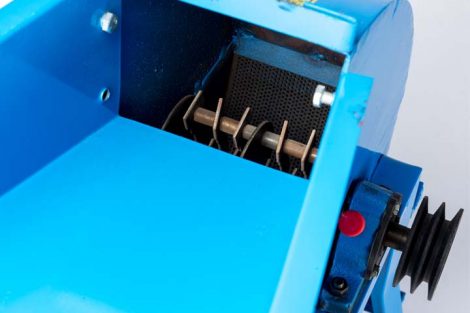

2. キャッサバ粉砕機

キャッサバ粉砕機はガリ加工ラインの重要な機械です。キャッサバの根は非常に長く、本体付近が木化しているため、折れずに粉砕することはできません。粉砕の目的は、グラインダーが正常に動作していることを確認することです。一部の工場では粉砕工程を行っていないため、粉砕機への負荷が増大し、寿命が短くなります。

運転時はモーターの温度や機械音に注意してください。音が突然小さくなった場合は、粉砕機内の材料が多すぎることを意味します。このとき、餌の量は減らす必要があります。破砕の品質は、今回の作業と次の工程の生産量に直接影響します。この機械はガリ加工機の中で重要な役割を果たしています。

3. プレス脱水機

キャッサバは、洗って皮をむき、砕いた後でも、まだ多量の水分を含んでいます。このときプレス脱水機で脱水する必要があります。本機はプレス脱水部、脱水バケット、載置台の3つの部分から構成されています。機械の運転を開始する前に、脱水プロセス中に排水口から材料が漏れないように、材料を細かい布で包む必要があります。運転中はプレス板を連続的にプレスし、脱水バケツ内の材料に圧力を加え続けることで脱水を行います。脱水バケツの底にはたくさんの水の出口穴があり、絞られた水は穴から載置台に流れ出ます。搬送台の両側には溝があり、プレス機を通った水が流れ出します。排水と回収に非常に役立ちます。

4.ガリ加工機のグラインダー

発酵したキャッサバ粉は再び凝縮して塊になるため、凝固したキャッサバ粉ブロックを再度粉砕する必要があります。粉砕工程は一次粉砕機と二次粉砕機に分かれていますが、なぜ2回に分けて粉砕する必要があるのでしょうか?まず、キャッサバが長すぎて、木化物質が多すぎるためです。一度潰してしまうと、挽ききれていない大きな粒が残ってしまい、味に影響を与える場合があります。 2つ目は、その後の炒め工程において、材料の大きさの違いによる加熱ムラの現象を防ぐためです。二次粉砕は通常、篩い分け後に行われます。

5. 中華鍋/ジャケット付き鍋

この機械にはさまざまな加熱方法があります。機械の上部にはモーターが装備されており、鍋内のスパチュラを制御して混合します。機械の内部にはサンドイッチがあり、最初の層は断熱層、2番目の層は加熱層です。中華鍋の底には排出口が設計されており、調理されたキャッサバ粉末はここから直接排出されます。この設計により、人的資源が節約され、人件費が削減されます。挽いたキャッサバ粉をこの鍋で炒めます。この機械は、均一な加熱、便利な排出、簡単な操作の特徴を備えています。

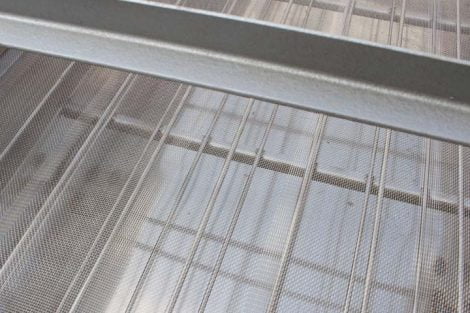

6. 三段ガリふるい機

粉砕工程における粉砕不均一現象により、キャッサバパウダーの粒度が異なり、食品の味に影響を与えます。そのため、炒めた後にふるい分けの工程が必要となります。この機械は、粒子の粉砕の細かさに応じて材料を3つのグレードに分けることができるため、三段ふるい分け機と呼ばれています。各段に排出口があり、機械の振動によりふるい分けた材料を排出することができます。より大きな粒子は、二次粉砕のために再び粉砕機に入れられます。最終製品の品質と味を保証します。

以下の点に特別な注意を払う必要があります。

上記の機械は、キャッサバ加工に使用される主要な機械です。厳密に言えば、全自動ガーリ生産ラインを形成するには、ホイストと最終包装機を追加する必要があります。Taizy machineryには、さまざまな出力を持つさまざまな種類のホイストと包装機があり、ニーズに応じて選択できます。もちろん、現在紹介されている生産ラインは固定されていません。機械を人手で代替できると感じた場合は、自由に購入できます。

さらに、キャッサバ原料の選択も重要です。デンプンの品質は、選択された原料と大きな関係があります。10ヶ月未満のキャッサバのデンプン含有量は低く、24ヶ月以上の古いキャッサバはリグニン化しています。継続的な加工と製造は、破砕および粉砕プロセスに大きな困難をもたらします。製品品質の低下とコストの増加の結果として、両方の要因が直接的な経済的損害をもたらします。したがって、最初のステップは原料の品質を確保することでなければなりません。

その他、より大きな出力のガリ加工機が必要な場合や、ワークショップの設計のお手伝いなど、ご要望がございましたら、お気軽にお問い合わせください。皆様のご協力を心よりお待ちしております。