エッグロールマシンは、多彩なエッグロール、クリスピーなワッフル、アイスクリームコーンの製造に使用できます。操作は簡単で、1人の操作者で管理可能です。

エッグロールマシンは、エッグロール、クリスピーなワッフル、クレープ、サンドイッチロール、アイスクリーム用ワッフルコーンなど、多様なスナックの製造に特化して設計されています。自動制御システムを備え、手作業の技術を再現し、操作は1人で可能です。

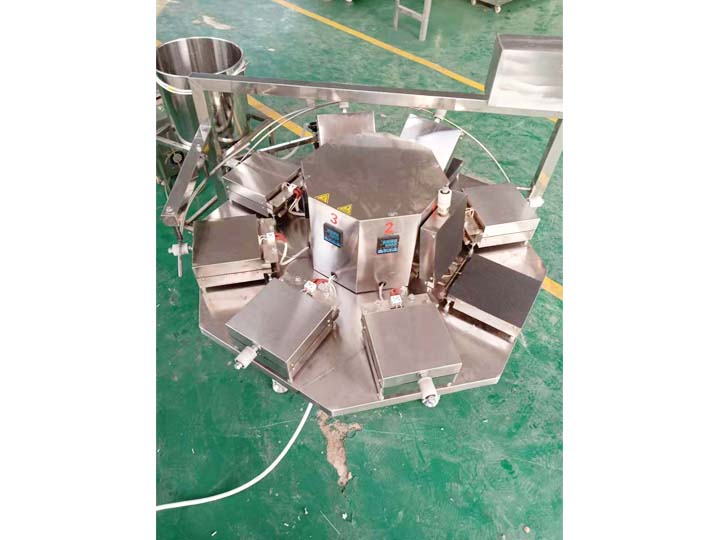

ヒーティングプレートは厚化された鋳鉄またはアルミニウム合金で構成されており、全体は304ステンレス鋼で作られています。これにより高温耐性と耐久性が確保され、各エッグロールが均一に色づき、カリカリに仕上がります。生産能力に関しては、

モデルは1時間あたり300〜1200キログラムの生産量を達成できます。8、10、または12のヒーティングプレートを備えた構成が利用可能で、小規模から大規模な生産ニーズに対応します。温度は正確に調整可能(160-200°C)、高い生産効率と一貫した製品品質を保証します。

エッグロール製造機の用途

エッグロールマシンは幅広い用途があります、次のとおり:

- スナック食品加工:ココナッツロール、タイのクリスピーロール、ハート型ロール、パイナップルロールなど、多様なクリスピーロールスナックを製造します。

- デザートおよびベーカリー業界:ケーキショップやベーカリーでクレープ、チョコレートロール、サンドイッチロールなどを製造するのに適しています。

- アイスクリームや冷凍お菓子業界:アイスクリーム用のワッフルコーンを製造し、夏の冷たいデザート市場の需要に応えます。

- グローバル市場対応:インドネシア、マレーシア、ベトナム、オランダ、中国、タイなどの国や地域に輸出され、多様な地域の顧客ニーズに対応。

エッグロールマシンの利点と特徴

- 高効率生産:1時間あたり300〜1200kgの連続運転が可能で、大規模な需要に対応します。

- インテリジェント操作:独立した温度制御ヒーティングプレートを備え、正確な温度調整と簡単で学びやすい操作を実現。

- 自動設計:自動バッター供給とスプリングプレート機能を備え、 manual laborを削減し、効率を向上させます。

- 多用途な生産:レシピに基づき、さまざまな味や形のエッグロールを作成可能。ヒーティングプレートや金型はカスタマイズ可能。

- 耐久性のある構造:厚化されたヒーティングプレートを備えた304ステンレス鋼で完全に作られ、長寿命を実現。

- 省エネ&エコフレンドリー:高効率の加熱技術を採用し、油や砂糖の使用量を最小限に抑え、清潔で衛生的な生産プロセスを確保します。

特別な注意

- エッグロールマシンには、8ヘッド、10ヘッド、12ヘッドの3タイプがあります。

- 卵焼き型の模様は、平、四角、縞があります。特別な要件がある場合は、カスタマイズのために 24 時間対応のオンライン カスタマー サービスにお問い合わせください。

- 加熱プレートのサイズはカスタマイズできます。

- さまざまな形状に巻くことができます:円筒形、フェニックスロール、アイスクリームコーンなど。

- 380Vと220Vの両方が使用可能です。

- 8 ヘッドのエッグ ローラーの出力は約 25 kg/h、10 ヘッドのエッグ ローラーは約 30 kg/h、12 ヘッドのエッグ ローラーは約 35 kg です。

エッグロールマシンはどのように動作しますか?

- まず、装置各部の取り付け状態が良好であることを確認し、メインスイッチを入れると電源表示灯が点灯します。

- 次に、電圧注入プラグと気管を挿入し、エアポンプを開きます。

- その後、操作ボタンが開きます。このとき、ターンテーブルとともに加熱ボックスが回転し、加熱スイッチが開きます。

- 一方、温度はインテリジェント温度コントローラーに表示されます。温度は必要な温度として事前に設定できます(エッグロールの厚さに応じて)。

- ペーストスティックを約5度上向きに傾け、加熱箱の中央に置きます。加熱する温度が設定温度と同じになったら、ペーストスイッチをオンにし、自動ペーストを開始します。

ワッフルメーカーの技術パラメータ

| モデル | サイズ(mm) | 電力(kw) | 電圧 | 重量(kg) | 能力(kg/h) |

| TZ-8 | 1500*1500*1200 | 18 | 380v/50hz | 420 | 10 |

| TZ-10 | 1650*1650*1200 | 22 | 380v/50hz | 470 | 12.5 |

| TZ-12 | 1800*1800*1200 | 27 | 380v/50hz | 520 | 15 |

一般的な問題

| よくある質問 | 原因 | アプローチ |

| ペーストの注入量が均一ではない | 生地や粒子が含まれている可能性があります。 | 混ぜるときは、卵焼きを顆粒や生地がなくなるまで混ぜ、ごまを加えてよく混ぜます。 |

| 貼らない | 1. シリンダー内のOリングが破損している。 2. ペースト中に大きな粒子が含まれています。 3. 圧力が異常な場合があります。 | 1. Oリングを交換してください。 2. 供給時に粒状の生地の出現を避けてください。 3. 空気圧を確認し、正常に調整してください。 |

| 製品の色ムラ | 1. 加熱温度が設定温度に達しません。 2. 温度センサーのプローブが緩んでいます。 3. 速度が速すぎるまたは遅すぎる。 | 1. 加熱温度が所定の温度になるまで待ってから貼り付けを開始します。 2. 温度センサーのプローブを締め付けてください。 3. 周波数変換器を適切な回転速度に繰り返し調整します。 |

| 動作不良 | 1. 周波数変換器の表示番号。 2. タイムリレーの取り付けがしっかりしていません。 | 1. 周波数変換器を交換してください。 2. タイムリレーをしっかりと取り付けてください。 |

| 製品の厚みが一定ではない | 圧縮スプリングロッドが緩んでいます。 | 圧縮スプリングのナットを調整してください。ナットの下側サポートからの高さは少なくとも10mmにしてください。 |

全体として、このエッグロールマシンは操作が簡単で、一貫した出力を提供し、エッグロール、クリスピーなワッフル、アイスクリームコーンの製造を目指すユーザーに最適です。

また、春巻きの皮を作る機械など、さまざまなスナック加工機も提供しています。労力を節約し、高効率で信頼性の高い機器をお求めの場合は、いつでもお気軽にお問い合わせください。構成や価格について詳しくご案内します!

- 役に立つ

5