설탕을 끓이는 것은 사탕, 케이크 및 땅콩 부스러기 간식과 같은 단 음식을 가공하는 일반적인 단계입니다. 시럽의 전문적인 과정에서는 균일한 가열, 높은 열 효율 및 제어 가능한 온도를 보장하기 위해 설탕 보일러 기계, 즉 재킷 냄비를 사용하는 것이 종종 필요합니다. 설탕 용해 냄비는 내부 및 외부 구형 냄비로 구성된 이중 구조이며, 중간 중간층은 열전도유 또는 증기로 가열됩니다. 설탕 용해 기계는 큰 가열 면적, 높은 열 효율, 고른 가열, 짧은 가열 시간 및 쉬운 온도 조절의 장점을 가지고 있습니다. 동시에, 시럽 조리 냄비는 재료의 끈적임을 피하기 위해 교반기가 장착되어 있습니다. 사탕 조리 기계는 시럽, 캐러멜, 사탕 및 기타 많은 액체 음식의 가공에 이상적인 장치입니다.

시럽을 만들 때 설탕 보일러 기계를 사용하는 이유는 무엇인가요?

시럽조리냄비의 뛰어난 장점은 다음과 같습니다.

- 넓은 가열 면적, 빠른 가열, 높은 열 효율 및 시간 절약;

- 가열은 균일하고 액체 재료의 끓는 시간은 짧습니다.

- 가열 온도는 제어하기 쉽고 고온은 320도에 도달할 수 있으며 보온 성능이 안정적입니다.

- 재킷 주전자의 재료는 냄비에 달라붙지 않으며 재료를 교반하는 형태는 균일한 교반을 보장하기 위해 바닥 긁기 및 가장자리 긁기 방식을 채택합니다.

- 재질이 위생적이고 안전합니다. 냄비의 내부 및 외부 껍질은 스테인레스 스틸로 만들어져 위생 및 안전 요구 사항을 충족하고 아름다운 외관을 가지고 있습니다.

- 작동이 쉽고 안전합니다. 냄비의 내부 층은 내산성, 내열성 스테인레스 스틸로 제작되었으며 압력계, 안전 밸브 및 전기 제어 상자가 장착되어 있습니다. 설탕 녹는 기계는 설치와 작동이 쉽습니다.

- 재료를 쉽게 부을 수 있습니다. 기울일 수 있는 재킷형 냄비는 최대 90°까지 기울일 수 있습니다.

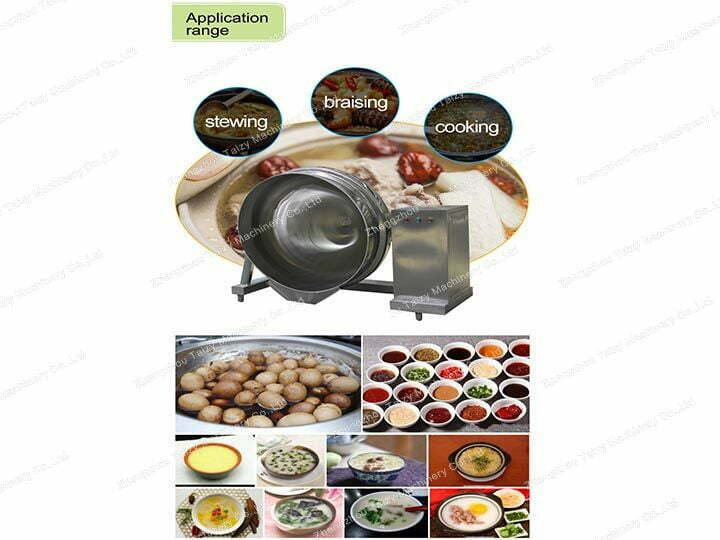

설탕 용광로의 적용 범위

재킷 냄비는 레스토랑에서 모든 종류의 음식(알코올, 과자, 약, 음료, 사탕, 통조림 식품, 유제품, 땅콩 사탕 및 기타 스낵, 스튜, 스튜, 수프, 죽 등)을 처리하는 데 널리 사용됩니다. 구내식당, 호텔 등

설탕 녹는 기계의 구조

스테인레스 스틸 설탕 보일러 기계는 주로 냄비 본체, 재킷, 팁 장치, 교반기 및 랙으로 구성됩니다. 랙은 화분 본체와 각종 장비를 설치하고 고정하는데 사용됩니다. 냄비 본체는 음식을 만드는 주요 부분입니다. 교반 패들은 수동 작업 대신 자동으로 접시를 저어줄 수 있습니다. 틸팅 장치는 냄비 본체의 전복 작동을 구현하는 데 사용됩니다. 가열 방법에 따라 시럽 보일러 기계는 전기 가열 재킷 냄비, 증기 재킷 냄비, 가스 재킷 냄비로 구분됩니다. 볼륨에는 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, 1000L이 포함됩니다.

시럽을 만드는 작업 단계는 무엇입니까?

1단계: 설탕과 물을 설탕 보일러 기계에 추가합니다. 끓일 설탕의 양은 총 용량의 약 2/3입니다.

2단계: 전기 가열 온도를 설정한 후 가열 스위치를 켭니다.

3단계: 설탕을 고르게 저어주기 위해 잠시 가열하여 녹은 후 교반 스위치를 켭니다.

4단계: 시럽이 끓을 때 더러운 거품이 생길 수 있습니다. 교반 스위치를 끄고 가능한 빨리 숟가락을 사용하여 청소합니다.

5단계: 고온 저항성이 있는 포도당 시럽을 추가합니다. 색상이 필요할 경우 약 130 ℃에서 색소를 추가하는 것이 적합합니다.

6단계: 온도가 필요한 온도에 도달하면 사탕 조리 기계는 즉시 가열을 중지합니다. 이때 메인 전원 스위치를 끄고 3~5분간 둡니다.