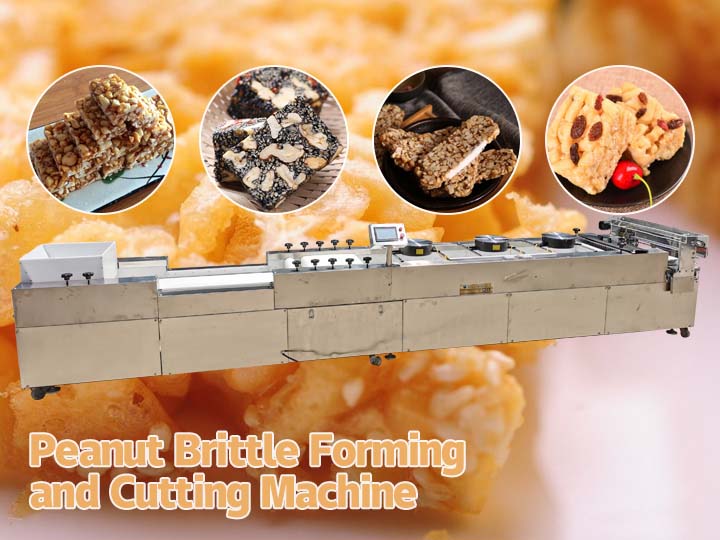

Peanut brittle making machine is also called peanut brittle forming and cutting machine. It is the main machine of the peanut brittle production line. Its application range is very wide, mainly used for automatic flattening and cutting of crispy candy such as Shaqima, puffed grain bar, peanut candy, sunflower seeds candy bar, miscellaneous grains bar. This machine imitates the traditional manual flattening and cutting principle. The material is automatically formed by continuous feeding pre-pressing and multi-pass rolling.

Working principle of the peanut brittle making machine:

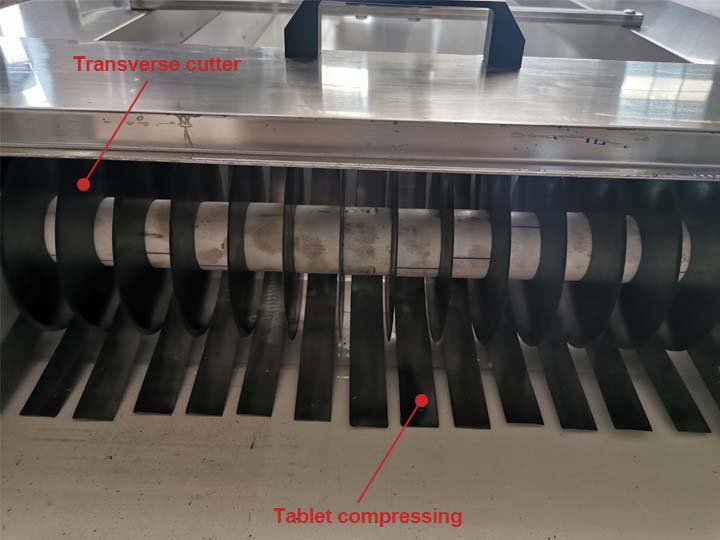

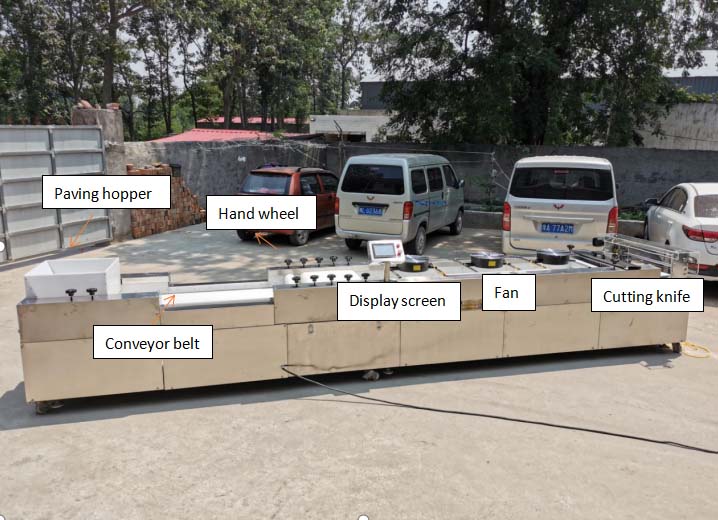

The peanut candy forming and cutting machine is mainly composed of a fuselage, a continuous automatic feeding system, a conveyor belt, a cooling fan, a pressing roller, a cross cutter, and vertical cutters.

The main workflow is: paving – conveying – flattening – cooling – re-pressing – cutting (vertical cutting) – linear horizontal axis (transverse cutting) – conveying – finished product.

- The whole body is made of 304 stainless steel. In line with international food safety and hygiene standards.

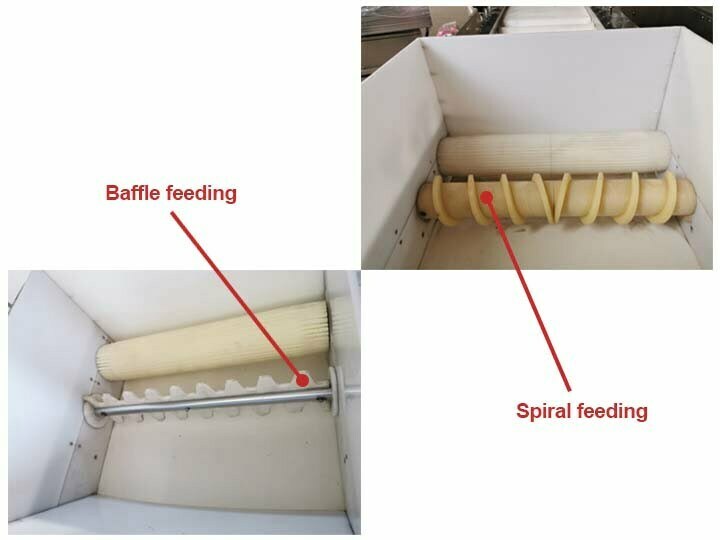

- The feeding system is divided into spiral type paving, which is suitable for continuous feeding; baffle type paving, suitable for one-time feeding.

- Six press rollers. One paving, four flattenings, one pre-cutting flattening. The pressing roller is solid and can withstand greater pressure, friction and wear resistance.

- The machine contains five motors. Paving motor (0.75KW), vertical cutter motor (0.75KW), cross cutter motor (0.25KW), main conveyor belt motor (1.5KW), conveyor belt motor (0.25KW).

- The conveyor belt is made of PP material, which is beautiful and elegant.

- The cooling step is mainly done by three fans (single voltage 220v/80w), which can be used either alone or simultaneously, through the control switch next to the fan. Cooling is to prevent the peanut candy from being so soft to form into pieces.

- Bracket and universal wheel: Can move or static placement.

The characteristics of peanut brittle making machine:

- It adopts PLC frequency conversion control, and the parameter setting is convenient. It can be operated automatically or manually.

- High sensitivity photoelectron eye-tracking automatically and accurately, with accurate feedback.

- The machine runs stably and operates conveniently. It solves the problem that traditional manual production consumes a lot of labor costs and has a high breakage rate.

- This machine can be continuously produced with high output.

- The peanut brittle machine is compact in structure and reasonable in layout.

- A wide range of applications. It can be applied to the production of a series of snack foods such as Shaqima, peanut crisp, and melon crisp.

- The viscous material is not easy to stick to the conveyor belt, and the cleaning is convenient.

How to adjust the thickness of the brittle block?

- The thickness of the dicing block is determined by the height of the pressing roller. And the height of the pressing roller can be adjusted by the control handwheel above the roller. The higher the distance of the roller from the conveyor belt, the thicker the dicing; the lower the distance of the roller from the conveyor belt, the thinner the dicing.

- The width of the dicing block is achieved by adjusting the number of vertical blades. The blade is 0.9mm thick and 150mm in diameter. These blades are made of high-speed steel and the cutting speed is fast. The conveyor belt has a width of 56 cm, that is, the width of the cut material is 56 cm.

The blade is sleeved on the main shaft. If you want to adjust the width of the cutting block, you first need to remove the screw and nut, then take out the sleeve with the knife, remove the blade, and place the number of blades according to the width you want.

- The vertical cutter portion has a blade and a pressing piece, and the pressing piece is for preventing the cutting piece from being rolled up due to the driving of the blade;

Cross-cutting knives, also known as linear bearings, ensure that the dicing is neat and uniform. The transverse cutter is equipped with a proximity switch, also known as an optoelectronic eye, which can be limited. There are shock absorber pads on both sides of the blade. It can protect the machine to the greatest extent and prolong its service life.

Technical parameters of peanut brittle making machine:

| Name | Voltage | Power | Output | Size |

| Peanut brittle making machine(main machine) | 380v | 2kw(0.75+0.75+0.25+0.25+1.5) | The yield is closely related to the thickness of the cut piece. The large the cutting size, the large the output. | 6.1m*1.25m*1.3m |

| Name | Voltage | Power | Size |

| Conveyor belt | 220v | 0.25kw | 5m*0.8m*0.7m |

In this table, we can know that the output of peanut brittle making machine is related to the thickness of the cut piece. Therefore, the specific production capacity is determined by your actual cutting size. The size of the machine is 6.1 * 1.25 * 1.3m.

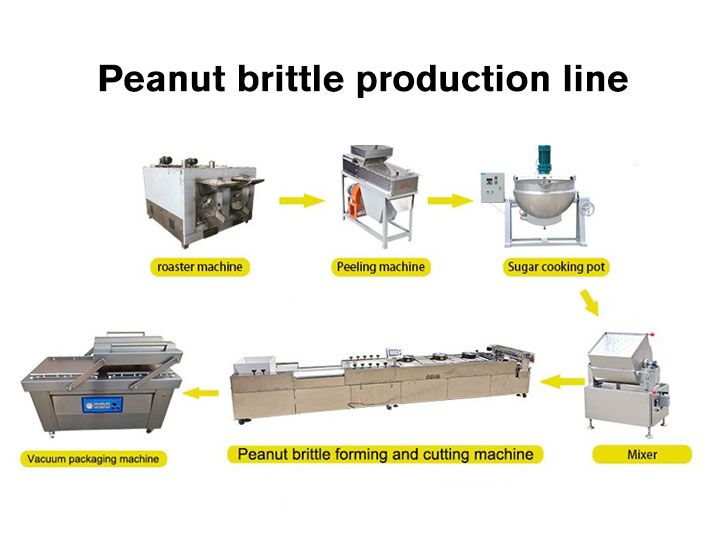

Related production line: