A máquina de rolinhos de ovo foi especificamente desenhada para produzir uma variedade de snacks, incluindo rolinhos de ovo, wafers crocantes, crepes, rolinhos de sanduíche e cones de waffle para gelado. Equipado com um sistema de controlo automatizado que replica a artesania manual, este dispositivo requer apenas um operador.

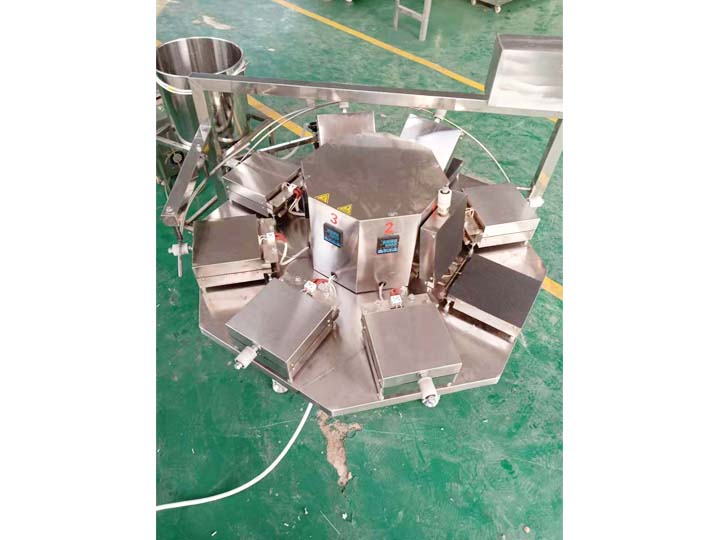

As placas de aquecimento são feitas de ferro fundido reforçado ou liga de alumínio, enquanto todo o corpo é feito de aço inoxidável 304. Isto garante resistência a altas temperaturas e durabilidade, assegurando que cada rolinho de ovo fique uniformemente dourado e crocante. Em termos de capacidade de produção,

os modelos podem atingir uma produção horária de 300 a 1200 quilogramas. Estão disponíveis configurações com 8, 10 ou 12 placas de aquecimento para atender às necessidades de produção de pequena a grande escala. A temperatura é ajustável com precisão (160-200°C), garantindo alta eficiência de produção e qualidade consistente do produto.

Aplicações de máquinas de fazer rolinhos de ovo

A máquina de rolinhos de ovo tem uma vasta gama de aplicações, incluindo:

- Processamento de alimentos snacks: produz vários snacks crocantes enrolados, como rolinhos de coco, rolinhos tailandeses crocantes, rolinhos em forma de coração e rolinhos de ananás.

- Indústria de sobremesas e padaria: adequada para lojas de bolos e padarias fabricarem crepes, rolinhos de chocolate, rolinhos de sanduíche e mais.

- Indústria de gelados e sobremesas congeladas: produz cones de waffle para gelado, atendendo às demandas do mercado de sobremesas congeladas de verão.

- Compatibilidade com o mercado global: equipamento exportado para Indonésia, Malásia, Vietname, Países Baixos, China, Tailândia e outros países/regiões, atendendo às diversas necessidades regionais dos clientes.

Vantagens e características da máquina de rolinhos de ovo

- Produção de alta eficiência: capaz de operação contínua com uma produção horária de 300–1200 kg, atendendo a uma demanda de grande escala.

- Operação inteligente: equipada com placas de aquecimento controladas independentemente para regulação de temperatura precisa e operação simples e fácil de aprender.

- Design automatizado: apresenta alimentação automática de massa e funções de placa de mola, reduzindo o trabalho manual e aumentando a eficiência.

- Produção versátil: capaz de criar rolinhos de ovo com vários sabores e formas, com placas de aquecimento e moldes personalizáveis.

- Construção durável: totalmente feito de aço inoxidável 304 com placas de aquecimento reforçadas para maior durabilidade.

- Eficiente em energia e ecológica: utiliza tecnologia de aquecimento de alta eficiência, minimiza o uso de óleo e açúcar, e garante um processo de produção limpo e higiénico.

Atenção especial

- Existem três tipos de máquinas de rolinhos de ovo: máquina de 8 cabeças, máquina de 10 cabeças, máquina de 12 cabeças.

- O padrão do molde para rolo de ovo é plano, quadrado e listrado. Se você tiver requisitos especiais, pode entrar em contato com o atendimento ao cliente online 24 horas por dia para personalização.

- O tamanho da placa de aquecimento pode ser personalizado.

- Vários formatos podem ser enrolados: cilíndrico, rolinho de fénix, cone de gelado, etc.

- Estão disponíveis 380V e 220V.

- A produção de rolos de ovos de 8 cabeças é de cerca de 25 kg / h, de rolos de ovos de 10 cabeças é de cerca de 30 kg / he de rolos de ovos de 12 cabeças é de cerca de 35 kg.

Como funciona a máquina de fazer rolinhos de ovo?

- Primeiramente verifique se a instalação de cada parte do aparelho está em boas condições, depois ligue a chave principal, neste momento a luz indicadora de energia está acesa.

- Em seguida, insira o plugue de tensão de injeção e a traqueia e abra a bomba de ar.

- Depois disso, o botão de operação é aberto. Neste momento, a caixa de aquecimento gira com a plataforma giratória e, em seguida, o interruptor de aquecimento é aberto.

- Enquanto isso, a temperatura é exibida no controlador de temperatura inteligente. A temperatura pode ser predefinida conforme a temperatura desejada (de acordo com a espessura do rolo de ovo).

- Ajuste a vara de pasta para que fique inclinada para cima cerca de 5 graus e coloque-a no centro da caixa de aquecimento. Quando a temperatura de aquecimento atingir a temperatura predefinida, ligue o interruptor de pasta, iniciando a alimentação automática.

Parâmetros técnicos da máquina de fazer waffles

| Modelo | Tamanho (mm) | Potência (kw) | Tensão | Peso (kg) | Capacidade (kg/h) |

| TZ-8 | 1500*1500*1200 | 18 | 380v/50hz | 420 | 10 |

| TZ-10 | 1650*1650*1200 | 22 | 380v/50hz | 470 | 12.5 |

| TZ-12 | 1800*1800*1200 | 27 | 380v/50hz | 520 | 15 |

Problemas comuns

| Perguntas frequentes | Causa | Abordagem |

| A quantidade de injeção de pasta não é uniforme | Podem haver massa e partículas nele. | Na hora de misturar, misture os rolinhos de ovo até ficarem sem grânulos ou massa, depois acrescente o gergelim e misture bem. |

| Sem colagem | 1. O anel de vedação no cilindro está quebrado. 2. Existem partículas grandes na pasta. 3. A pressão pode estar anormal. | 1. Substitua a junta O. 2. Evite a aparência de massa granular ao alimentar. 3. Verifique a pressão do ar, ajuste para o normal. |

| Cor irregular do produto | 1. A temperatura de aquecimento não atinge a temperatura definida. 2. A sonda de deteção de temperatura está solta. 3. A velocidade é demasiado rápida ou demasiado lenta. | 1. Espere até que a temperatura de aquecimento seja igual à temperatura predeterminada antes de começar a colar. 2. Aperte a sonda de deteção de temperatura. 3. Ajuste repetidamente o conversor de frequência para a velocidade de rotação apropriada. |

| Mau funcionamento | 1. O número exibido no display do conversor de frequência. 2. A instalação do relé de tempo não está firme. | 1. Substitua o conversor de frequência. 2. Instale o relé de tempo firmemente. |

| A espessura do produto é inconsistente | A haste do molas de pressão está solta. | Ajuste a porca na mola de compressão; a altura da porca desde o suporte inferior deve ser de pelo menos 10mm. |

No geral, esta máquina de rolinhos de ovo é fácil de operar e fornece uma produção consistente, tornando-a ideal para utilizadores que desejam produzir rolinhos de ovo, wafers crocantes ou cones de gelado.

Também oferecemos uma variedade de outras máquinas de processamento de snacks, como máquinas de envolver rolinhos primavera. Se procura equipamento de poupança de trabalho, alta eficiência e qualidade fiável, não hesite em contactar-nos a qualquer momento para saber mais sobre configurações e preços!

- Útil