O espremedor de maracujá pode realizar todo o processo de quebra da casca e extração do suco → descasque → separação de sementes e polpa (pureza da separação > 98%). Usando esta máquina, é possível obter diretamente polpa com zero oxidação ao mesmo tempo, além de melhorar a integridade das sementes da fruta para 95%. Atende às necessidades de produção de bebidas de suco, produtos de polpa de fruta e processamento profundo de sementes.

Avanço central:

- Aumento de eficiência: produção de 500-1000kg/hora, operação contínua de 4 horas sem problemas.

- Garantia de material: toda a máquina em aço inoxidável 304 de grau alimentar, resistência à corrosão com vida útil de até 10 anos +.

- Adaptação inteligente: design modular compatível com citrinos, romã e outras mais de 20 categorias de frutas.

- Valor agregado: pectina da casca da fruta, óleo essencial das sementes da fruta, taxa de utilização da matéria-prima de até 99%.

Cenários de aplicação do extrator de suco de frutas

- Extrair rapidamente a polpa do maracujá para fazer suco de fruta fresco, bebidas especiais (como chá de maracujá, água com gás).

- Fornecer suco fresco para a área de buffet e sobremesas, apoiar o processamento em lote.

- Extrair polpa para recheio de bolos, mousse e outros ingredientes de sobremesas, e separar sementes para coberturas decorativas.

- Linha de produção integrada com equipamentos de esterilização e enchimento para produzir suco engarrafado/enlatado.

- A casca separada é usada para ferver pectina, e a polpa é usada para fazer geleia, realizando zero desperdício de matérias-primas.

- As sementes de frutas são processadas para extrair óleo essencial ou fazer pó de fruta, que pode ser usado em barras de nutrição, gelatina e outros produtos.

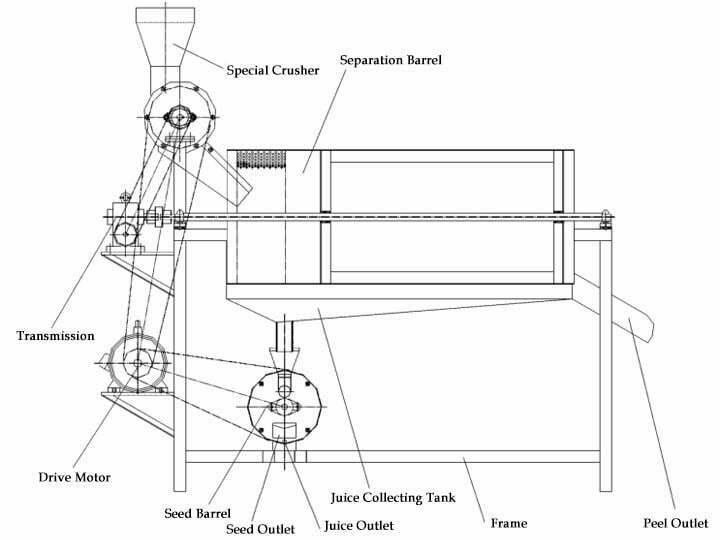

Princípios estruturais principais do espremedor de maracujá

- A fruta da paixão entra no triturador especial através da entrada, é triturada pelos dentes de trituração e, em seguida, entra no cilindro de separação.

- Dentro do cilindro separador, o suco, a polpa e a casca são separados por rotação, a casca é descarregada do funil de bagaço, e o suco e a polpa fluem para o tanque de coleta de suco, e depois para o cilindro de sementes com raspador de borracha.

- O raspador de borracha irá raspar o suco do buraco do cilindro de sementes, o suco passará pela saída para o próximo processo, as sementes serão descarregadas pela saída de sementes, realizando a separação eficaz da casca da fruta, sementes e suco.

Principais parâmetros técnicos do espremedor comercial

| Nome | Espremedor/extrator de suco |

| Capacidade de processamento | 0,5-1T/H |

| poder | 2,2 kW |

| tamanho | 1900×850×2260mm |

| Os parâmetros acima são apenas para referência | |

Operação e manutenção do espremedor automático

Verificações pré-operação

- Certifique-se de que as partes rotativas se movem suavemente; verifique a tensão da correia/corrente.

- Verifique se a rotação do motor corresponde à direção indicada.

Durante a operação

- Monitore a taxa de quebra de sementes, limpeza e separação de polpa-semente. Ajuste o espaço do raspador de borracha se necessário.

- Se a taxa de perda de sementes for alta, levante o suporte do funil de resíduos. Se a descarga de polpa estiver lenta, abaixe-o.

- Alimente apenas após a partida; pare apenas após todas as sementes/polpa serem descarregadas.

Limpeza e segurança

- Limpe as sementes/resíduos com água se necessário.

- Nunca insira as mãos na máquina enquanto estiver em funcionamento.

- Evite objetos duros (pedras, metal) para prevenir danos.

Manutenção

- Lubrifique regularmente os rolamentos antes de usar o espremedor de maracujá.

Diagrama da estrutura da máquina de processamento de suco de maracujá.

Linha de produção de suco de maracujá (rendimento: 1 tonelada/hora).

Maracujá fresco – sem lesões, escovagem cega – desinfeção – sementes da casca sem detritos, cortando pétalas – separação das sementes da casca sem detritos – obter polpa de fruta separada, casca.

Produtos e especificações

- Matérias-primas e requisitos: maracujá fresco, que não viole as disposições da Lei de Segurança Alimentar sobre a qualidade das matérias-primas. A maturidade deve ser superior a 70%. Não deve estar podre, mofado ou com odor.

- Produto principal: polpa de maracujá pura, sementes. A pureza e as impurezas atendem aos padrões relevantes. A cor, aroma, sabor e forma mantêm a qualidade natural da fruta original.

- Subproduto: casca de quatro pétalas com forma regular. Pode ser usada como ração fermentada ou fruta preservada, fibra dietética, colchão, almofada, travesseiro, etc.

Toda a linha apresenta

- Todo o material em aço inoxidável, bonito e durável, em conformidade com os padrões de higiene de grau alimentar.

- Corte e separação totalmente selados para evitar contaminação e atender às normas modernas de segurança alimentar na produção.

- Operação automatizada, reduzindo a intervenção manual, podendo substituir mais de 30 tarefas manuais, reduzindo custos de mão de obra.

- Pode processar vários tipos de maracujá, como frutas enrugadas, frutas com cicatrizes, frutas de pele clara, frutas com ponta, etc., com forte aplicabilidade.

- O produto principal (suco/pulpa) tem alta pureza, baixa impureza e baixo teor bacteriano, o que é conveniente para embalagem, armazenamento e preservação da frescura.

- Os subprodutos (casca/semente) têm forma regular, o que é favorável para processamento adicional e produção limpa.

Condições de colocação e operação (excluindo armazéns e câmaras frias).

- Área da planta para a linha de produção: 60㎡.

- Consumo de água por hora na linha de produção: 1 t.

- Consumo de eletricidade por hora na linha de produção: 20 kW.

- Consumo horário de vapor na linha de produção: não é utilizado vapor.

- O número de trabalhadores utilizados na linha de produção: 1-2.

- Limpe o suco com um lavadora de frutas antes de apertar.

Lista de serviços da máquina de suco de maracujá

| Número | Nome do dispositivo | Tipo de especificação | Observações |

| 1 | Talha não destrutiva para maracujá | Saída: 1t/h Potência: 0,75kWPeso: 120kgTamanho: 3×0,8×1,8 m | Melhorar sem ferir a fruta. Correia transportadora de plástico de engenharia de grau alimentar. Velocidade ajustável. Com uma plataforma de alimentação. |

| 2 | Máquina de escovação cega não invasiva | Capacidade de processamento: 1t/h Potência: 3 kW Peso: 780kg Tamanho: 3.2×1.3×1.8m | Aço inoxidável como material principal, Omron do Japão para PLC, uma marca bem conhecida para componentes eletrónicos. Controle de computador de máquina, estrutura mecatrônica. Pode limpar a fruta sem danos, sem pontos cegos, e garantir que o produto atenda ao padrão de qualidade. Velocidade da máquina ajustável, reciclagem de água. |

| 3 | Máquina de desinfecção por ozônio | Saída: 1t/h Potência: 5.2kW Peso: 420kg Tamanho: 3×0.8×1.8 m | A máquina é composta por uma estrutura, tanque de água, correia transportadora e gerador de ozono. Alimentação e descarga automáticas contínuas. Velocidade ajustável, filtração de água e reciclagem. |

| 4 | Talha de posicionamento automático (encaixe automático com a máquina de corte) | Saída: 1t/h Potência: 1.1kW Peso: 320kg Tamanho: 2×0.8×1.8 m | Posicionamento automático, acoplamento com o cortador. Correia transportadora de plástico de engenharia de grau alimentar. Velocidade ajustável. |

| 5 | Máquina de corte de pele e sementes sem resíduos | Saída: 1t/h (≈300 frutas por minuto) Número de cortes: 4 Potência: 0.37kW Peso: 150kg Tamanho: 0.8×0.8×1m | Aço inoxidável, uma marca famosa para componentes eletrónicos. Facas especiais e afiadas são usadas para garantir que a fruta seja cortada em quatro pétalas com pouco resíduo. Acoplamento automático com separador e operação de selagem. |

Escolha o nosso espremedor de maracujá e inicie uma nova era de processamento de fruta eficiente, higiénico e sustentável. Da polpa fresca a sementes intactas, da produção automatizada à utilização com desperdício zero, ajudamo-lo a conquistar o mercado e a criar competitividade diferenciada! Solicite já soluções exclusivas!