The passion fruit juicer can realize the whole process of shell breaking and juicing → peel peeling → seed and flesh separation (separation purity > 98%). Using this machine to directly obtain zero oxidation pulp at the same time, but also to improve the integrity of the fruit seeds to 95%. It meets the production needs of juice drinks, fruit meat products and deep processing of seeds.

Core breakthrough:

- Efficiency jump: 500-1000kg/hour production, 4-hour continuous operation without trouble.

- Material guarantee: the whole machine 304 food-grade stainless steel, corrosion resistance life of up to 10 years +.

- Intelligent adaptation: modular design compatible with citrus, pomegranate, and other 20+ berry categories.

- Value-added: pectin from fruit peel, essential oil from fruit seeds, raw material utilization rate up to 99%.

Application scenarios of fruit juice extractor

- Quickly extract passion fruit pulp to make fresh fruit juice, specialty drinks (such as passion fruit tea, sparkling water).

- Provide fresh juice supply for buffet and dessert area, support batch processing.

- Extract pulp for cake sandwich, mousse and other dessert ingredients, and separate seeds for decorative toppings.

- Integrated production line with sterilization and filling equipment to produce bottled/canned juice.

- Separated peel is used to boil pectin, and pulp is used to make jam, realizing zero waste of raw materials.

- Fruit seeds are further processed to extract essential oil or make fruit powder, which can be used in nutrition bar, jelly and other products.

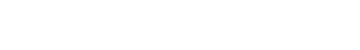

Passion fruit juicer main structural principles

- Passion fruit enters the special crusher through the inlet, is crushed by the crushing teeth and then enters the separation cylinder.

- Inside the separating cylinder, the juice, pulp and peel are separated by rolling, the peel is discharged from the pomace hopper, and the juice and pulp flow into the juice collecting tank, and then into the seed cylinder with rubber scraper.

- Rubber scraper will scrape the juice from the seed cylinder hole, the juice through the outlet into the next process, the seeds are discharged from the seed outlet, realizing the effective separation of fruit skin, seeds and juice.

Commercial juicer main technical parameters

| Name | Juicer/Juice extractor |

| Processing capacity | 0.5-1T/H |

| power | 2.2KW |

| size | 1900×850×2260mm |

| The above parameters are for reference only | |

Operation and maintenance of automatic juicer

Pre-operation checks

- Ensure rotating parts move smoothly; check belt/chain tension.

- Verify motor rotation matches the indicated direction.

During operation

- Monitor seed breakage rate, cleanliness, and flesh-seed separation. Adjust the rubber scraper gap if needed.

- If seed loss rate is high, raise the residue hopper rack. If pulp discharge is slow, lower it.

- Feed only after startup; stop only after all seeds/pulp are discharged.

Cleaning & safety

- Clean residual seeds/pulp with water if necessary.

- Never insert hands into the machine while running.

- Avoid hard objects (stones, metal) to prevent damage.

Maintenance

- Regularly lubricate bearings before using the passion fruit juicer.

Passion juice processing machine structure diagram

Passion fruit juice production line (yield: 1 ton/hour)

Fresh passion fruit – no injury, blind brushing – disinfection – skin seeds without debris, cutting petals – skin seeds without debris separation – get separated fruit pulp, peel.

Products and specifications

- Raw materials and requirements: fresh passion fruit, which does not violate the provisions of the Food Safety Law on the quality of raw materials. Maturity is more than 70%. It must not be rotten, mildewed, or odorous.

- Main product: pure passion fruit pulp, seeds. Purity and impurities meet the relevant standards. The color, aroma, taste, and shape maintain the natural quality of the original fruit.

- By-product: four-petal peel with regular shape. It can be used as a fermented feed or preserved fruit, dietary fiber, mattress, cushion, pillow, etc.

The whole line features

- All stainless steel material, beautiful and durable, in line with food grade hygiene standards.

- Fully sealed cutting and separating to avoid contamination and meet modern food safety production norms.

- Automated operation, reducing manual intervention, can replace 30+ manual tasks, reducing labor costs.

- It can process various passion fruit types such as wrinkled fruit, scarred fruit, light skin fruit, tipped fruit, etc., with strong applicability.

- The main product (juice/pulp) has high purity, low impurity, and low bacterial content, which is convenient for packaging, storage, and freshness preservation.

- The by-products (peel/seed) are in regular shape, which is favorable for further processing and clean production.

Placement and operating conditions (excluding warehouses and cold storage)

- Plant area for production line: 60㎡.

- Water consumption per hour in the production line: 1 t.

- Electricity consumption per hour in the production line: 20 kW.

- Hourly steam consumption in the production line: no steam is used.

- The number of workers used in the production line: 1-2.

- Clean the juice with a fruit washer before squeezing.

Passion fruit juicer machine service list

| Number | Name of device | Specification type | Remarks |

| 1 | Passion fruit non-destructive hoist | Output: 1t/h Power: 0.75kWWeight: 120kgSize: 3×0.8×1.8 m | Improve without hurting the fruit. Food-grade engineering plastic conveyor belt.Adjustable speed.With a feeding platform. |

| 2 | Non-invasive blind brushing machine | Processing capacity: 1t/h Power: 3 kWWeight: 780kgSize: 3.2×1.3×1.8m | Stainless steel for main material, Omron of Japan for PLC, a well-known brand for electronic components. Machine computer control, mechatronic structure. Can clean the fruit without damage, with no blind spots, and ensure that the product meets the standard of quality.Adjustable machine speed, water recycling. |

| 3 | Ozone disinfection machine | Output: 1t/h Power: 5.2kWWeight: 420kgSize: 3×0.8×1.8 m | The machine is composed of a frame, water tank, conveyor belt, and ozone generator. Continuous automatic feeding and discharging.Adjustable speed, water filtration, and recycling. |

| 4 | Automatic positioning hoist

(automatic docking with the cutting machine) | Output: 1t/h Power: 1.1kWWeight: 320kgSize: 2×0.8×1.8 m | Automatic positioning, docking with the cutter. Food-grade engineering plastic conveyor belt.Adjustable speed. |

| 5 | Skin, seed without debris cutting machine | Output: 1t/h (≈300 fruits per minute)Number of cuts: 4Power: 0.37kWWeight: 150kgSize: 0.8×0.8×1m | Stainless steel, a famous brand for electronic components. Special sharp knives are used to ensure that the fruit is cut into four petals with little debris.Automatic docking with separator and sealing operation. |

Choose our passion fruit juicer and start a new era of efficient, hygienic, and sustainable fruit processing. From fresh pulp to intact seeds, from automated production to zero-waste utilization, we help you capture the market and create differentiated competitiveness! Inquire now for exclusive solutions!