The egg roll machine is specifically designed for producing a variety of snacks, including egg rolls, crispy wafers, crepes, sandwich rolls, and waffle cones for ice cream. Equipped with an automated control system that replicates manual craftsmanship, this device requires only one operator.

Heating plates are constructed from thickened cast iron or aluminum alloy, while the entire body is made of 304 stainless steel. This ensures high-temperature resistance and durability, guaranteeing each egg roll is evenly colored and crispy. In terms of production capacity,

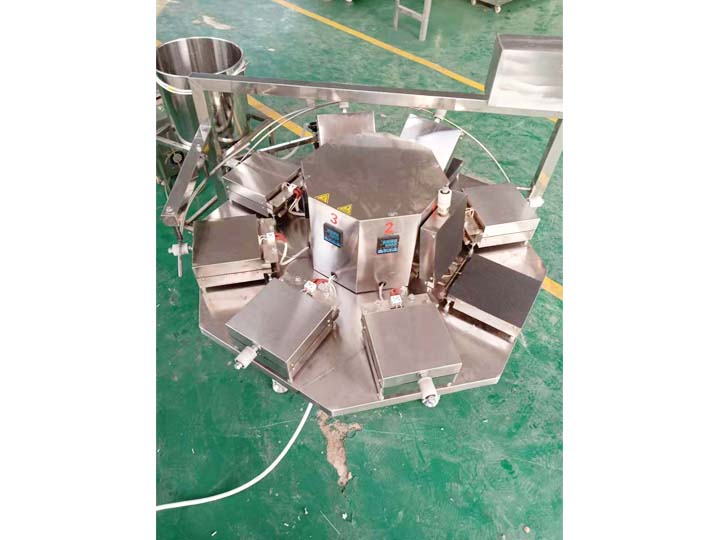

models can achieve hourly outputs ranging from 300 to 1200 kilograms. Configurations with 8, 10, or 12 heating plates are available to accommodate small-scale to large-scale production needs. Temperature is precisely adjustable (160-200°C), ensuring high production efficiency and consistent product quality.

Applications of egg roll making machines

The egg roll machine has a wide range of applications, including:

- Snack food processing: produces various crispy rolled snacks such as coconut rolls, Thai crispy rolls, heart-shaped rolls, and pineapple rolls.

- Dessert and bakery industry: suitable for cake shops and bakeries to manufacture crepes, chocolate rolls, sandwich rolls, and more.

- Ice cream and frozen treats industry: produces waffle cones for ice cream, meeting summer frozen dessert market demands.

- Global market compatibility: equipment exported to Indonesia, Malaysia, Vietnam, the Netherlands, China, Thailand, and other countries/regions, catering to diverse regional customer needs.

Egg roll machine advantages and features

- High-efficiency production: capable of continuous operation with an hourly output of 300–1200 kg, meeting large-scale demand.

- Intelligent operation: equipped with independently temperature-controlled heating plates for precise temperature regulation and simple, easy-to-learn operation.

- Automated design: features automatic batter feeding and spring plate functions, reducing manual labor and boosting efficiency.

- Versatile production: capable of creating egg rolls in various flavors and shapes based on recipes, with customizable heating plates and molds.

- Durable construction: entirely made of 304 stainless steel with thickened heating plates for extended service life.

- Energy-efficient & eco-friendly: utilizes high-efficiency heating technology, minimizes oil and sugar usage, and ensures a clean, hygienic production process.

Particular attention

- There are three types of egg roll machines: 8-head egg roll machine, 10-head egg roll machine, 12-head egg roll machine.

- The pattern of egg roll mold has flat, square and stripe. If you have special requirements, you can contact 24 hours online customer service for customization.

- The size of the heating plate can be customized.

- Various shapes can be rolled: cylindrical, phoenix roll, ice cream cone, etc.

- Both 380V and 220V are available.

- The output of 8-head egg rollers is about 25 kg/h, 10-head egg rollers are about 30 kg/h and 12-head egg rollers are about 35 kg.

How does the egg roll machine work?

- First, check whether the installation of each part of the device is in good condition, then turn on the main switch, at this time the power indicator light is on.

- Then insert the injection voltage plug and trachea, and open the air pump.

- After that, the operation button is opened. At this time, the heating box rotates with the turntable, and then the heating switch is opened.

- Meanwhile, the temperature is displayed on the intelligent temperature controller. The temperature can be preset as the required temperature (according to the thickness of the egg roll).

- Adjust the paste stick so that it is tilted upwards by about 5 degrees and placed in the middle of the heating box. When the temperature to be heated is the same as the preset temperature, the paste switch is turned on, and the automatic paste is initiated.

Waffle maker machine technical parameters

| Model | Size(mm) | Power(kw) | Voltage | Weight(kg) | Capacity(kg/h) |

| TZ-8 | 1500*1500*1200 | 18 | 380v/50hz | 420 | 10 |

| TZ-10 | 1650*1650*1200 | 22 | 380v/50hz | 470 | 12.5 |

| TZ-12 | 1800*1800*1200 | 27 | 380v/50hz | 520 | 15 |

Common problems

| FAQ | Cause | Approach |

| The amount of paste injection is not uniform | There may be dough and particulate in it. | When mixing, mix the egg rolls until no granules or dough, then add sesame and mix well. |

| No-pasting | 1. The O-ring in the cylinder is broken. 2. There are large particles in the paste. 3. Pressure may be abnormal. | 1. Replace the O-ring. 2. Avoid the appearance of granular dough when feeding. 3. Check the air pressure, adjust to normal. |

| Uneven color of the product | 1. Heating temperature does not reach the set temperature. 2. The temperature sensing probe is loose. 3. The speed is too fast or too slow. | 1. Wait until the heating temperature is the same as the predetermined temperature before starting to paste. 2. Tighten the temperature sensing probe. 3. Repeatedly adjust the frequency converter to the appropriate rotation speed. |

| Poor operation | 1. The frequency converter display number. 2. Installation of the time relay is not firm. | 1. Replace the frequency converter. 2. Install the time relay firmly. |

| Product thickness is inconsistent | The pressure spring rod is loose. | Adjust the nut on the compression spring; the height of the nut from the lower support shall be at least 10mm. |

Overall, this egg roll machine is simple to operate and delivers consistent output, making it ideal for users looking to produce egg rolls, crispy wafers, or ice cream cones.

We also offer a variety of other snack processing machines, such as spring roll wrapper machines. If you’re seeking labor-saving, high-efficiency equipment with reliable quality, feel free to contact us anytime to learn more about configurations and pricing!

-

Useful