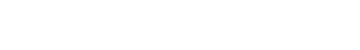

Almond slicer is the main machine for cutting almonds. And it can slice not only almonds, but also all kinds of nuts, such as peanuts, hazelnuts, walnuts, macadamia nuts, etc. The use of sliced almonds and peanuts is very wide, such as biscuits, cakes, ice cream, and other food surfaces. Because people can sprinkle a small amount of almond slices and peanut slices on it for decoration. In addition, the cut almond slices and peanut slices can be processed twice to make peanut brittle, almond sugar, or moon cake fillings. The processing technology of these foods is closely related to the almond slicer.

The working principle of the nuts slicer is as follows

Almond cutting machine has two main components, namely the pneumatic feeding device and slicing device. When making production, first put almonds and peanuts into the hopper. Then the kernels are pressed into the cutter head by the pneumatic device, and the slices of the kernels are cut out. It can adjust the thickness of the slices according to the need to meet the requirements of use. The motor adopts frequency conversion speed regulation to adjust the output of the slices. The pressing mechanism adopts pneumatic device to adjust the pressure so as to achieve the best effect.

Technical parameters of an almond slicer

| Size | 1000x550x1500mm |

| Power | 1.5KW |

| Input pressure | 0.3-0.4 Mpa |

| Power supply | 3P/380V |

| Capacity | 50-200 KG/H |

Installation and commissioning of the almond cutting machine

- Turn on the power and pay attention to whether the spindle cutter is turning correctly. The motor of the almond cutting machine is an electromagnetic speed-regulating motor. We can adjust the speed of the cutter head according to the actual requirements of the material.

- Connect to the air source, use the 8mm diameter pipe to connect clean compressed air from the pressure regulating valve, and adjust the air pressure to 0.3-0.4Mpa.

- To adjust the working frequency of the cylinder, the lifting time of the general cylinder is generally 3-4 seconds. The pressing time is generally adjusted to 15-30 seconds according to the different thickness and the speed of the cutter head. The pressing time is suitable for cutting the material in the cylinder completely.

- The thickness of the slice is adjustable. Then add clean nuts into the hopper for continuous slicing. When you want to change the thickness of the slice, you can loosen the lock nut under the thin handle. Adjusting the handle in a clockwise direction increases the thickness, and conversely decreases the thickness. A rotation of one week will give an impression thickness of 1.5 mm. Thickness can be mediated as required. After adjustment, the nut needs to be re-locked.

Precautions

- The nuts should not be too dry. If the materials are too dry, they should be soaked and then dried to slice.

If the material is too dry, the slices are easily broken. If the water content is too high, the chips may accumulate on the cutter head and the discharge port.

- Screen out impurities because there may be sand and stones in the raw materials, which will damage the blade edge.

- The working pressure of the cylinder should not be too high. It is advisable to control it at 0.3-0.4 Mpa. If the pressure is too low, it is easy to break and not whole. If the pressure is too high, it will cause jitter and uneven slice thickness.

- Change the blade. Almond cutting machine has two high-speed steel blades on the rotary cutting disc. When the edge of the blade is blunt and not sharp, or when there are sand grains and small stones in the kernels, the blade will collapse. At this time, we should replace the blade. When changing the knife, open the front door of the discharge port, open the round cover on the nut slicer surface. Remove the blade from the rotating disc by removing the two m6 bolts with a wrench.(The two nuts are under the rotary cutting disc.)At this point, you can replace the blade with a new one.

Advantages of the Almond Slicer

- The almond slicer machine is made of stainless steel, and the outer cover of the fuselage is made of stainless steel. The parts in contact with the materials are all food-grade stainless steel, which meets the food hygiene requirements.

- The material of blade is high-quality high-speed steel. So, this almond slicer has a sharp edges and long service life.

- Wide range of uses. This machine can not only cut almond, but also cut flower raw kernel, cashew nut, walnut kernel, hazelnut and so on. So, this is a special device.

- The almond nut slicer has the characteristics of moisture-proof, dust-proof and oil-proof. Therefore, it has the safety devices.

Video

How to use the peanut slicer?