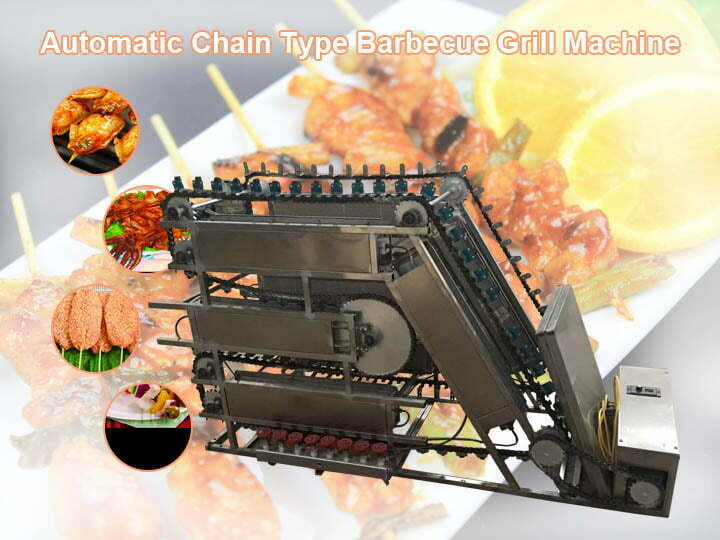

チェーン式自動バーベキューグリル機は、新しいタイプのバーベキュー設備です。ガス加熱方式を用いて焼き串を連続的に加熱しました。バーベキューの過程で煙や粉塵が発生しません。

自動チェーン式バーベキューグリル機の構造:

このバーベキューマシンは主に保護カバー、チェーン装置、加熱装置、電力制御装置で構成されています。

- シールドは主に機体本体を保護するためのものです。

- バーベキューグリル機の左右には長さ5メートルのチェーンが2本あり、チェーンにはケバブを乗せるためのソケットが付いています。ソケットはスプリングチャックとユニバーサルジョイントソケットで構成されています。抜き差ししやすくとても便利です。お客様のさまざまなニーズに応じて、ソケットの数は60〜90の間で調整できます。

- バーベキューグリル機で消費する燃料は、 液化石油ガス、加熱源は 4 つのグループ (8 個) の赤外線バーナーによって提供され、加熱は均一です。各赤外線バーナーは個別に制御して、さまざまな温度要件の制御を実現できます。

- パワーコントローラーは機械全体の動作を制御することができます。優れた電気部品を使用しており、耐用年数は5~10年です。

自動ガスバーベキューグリル機の動作原理:

バーベキューグリルマシンのチェーンは 120 ワットの可変速度モーターによって駆動され、オペレーターは速度を調整して適切な動作速度を達成できます。 2つのチェーングループの真ん中にあるのは、ミートケバブのランニングスペースです。串と2組のチェーンは常に水平状態です。チェーンは 75 個の焼き製品を駆動し、4 つのグループの赤外線バーナーの周りを反時計回りに循環させます。 4組のバーナーの燃焼面は地面に対して垂直で、側面から中央に熱が伝わり、焼き菓子の表面に照射される熱を100~300℃まで自由に調節できます。

焼き上がりがチェーンで上層に移動すると、赤外線バーナーが串の底を焼きます。焼き上がった製品が赤外線バーナーの 2 層目まで流れる間に、ケバブの上部が焼き上がります。ケバブがバーナーの3層目を通過すると、ケバブの底が焼き上がります。傾斜バーナーの 4 番目のグループは、温度を補償するために使用されます。同時に、熱風の上方移動の原理を利用して、第2層と第3層の熱損失が機械の第1層に上昇し、エネルギー目的を達成するために最上層を繰り返し再加熱できます。 -節約。

無煙・無塵グリルの利点:

- オールステンレス製の胴体。食品衛生基準に適合した美しい外観。

- チェーンバーベキューモードを採用し、加熱が均一で、バーベキュー時間が短く、ランプブラックが生成されません。

- 赤外線バーナーはカーボンファイバー加熱チューブを使用して設計されており、一部の特別な場所での直火の使用が制限されるという問題を解決します。その用途はより広範囲に及び、死角なしで 360 度の加熱に達することができます。

- 熱気流の上方移動の原理を利用して、失われた熱をバーベキューグリルの上部で再利用して、省エネの目的を達成することができます。

他のグリルとの利点の比較:

従来のグリルとの比較:

- 炭火焼きの煙や粉塵は非常に不衛生で環境を汚染します。

- 炭火は温度が不安定なため、焼き上がりが均一に加熱されず、効率が悪くなります。また、燃やした木炭を備蓄する必要があり、高価で高価です。

- オペレーターに対する技術要件は高く、熟練した経験が必要です。そうしないと、ケバブが未熟になったり、加熱しすぎたりする現象が発生しやすくなります。

- ワンアクション操作で1時間の生産速度の比較:従来のバーベキューマシンは100~200本の串、本機は500~800本の串を作ることができます。

- このバーベキューマシンの出力品質とスピードを達成するには、数倍の人手が必要です。

通常のバーベキューグリルと比較すると、

- 製品品質のコントラスト: 通常のグリルでは加熱ムラが発生し、串焼きの味が悪くなってしまいます。このグリル内のすべての焼き製品は360度で均一に加熱され、同じ品質になります。ベーキングプロセスは無煙で粉塵も出ません。

- ガス消費量の比較: 通常のグリルは1.5〜2kgのガスを消費しますが、このバーベキューマシンは2kgです。

- 経済的利益の比較: バーベキューマシンは一度に数千元の投資で5〜10年の使用が可能で、このマシンを操作できるのは1人だけです。

- 人件費の比較: 通常のグリルがこのバーベキューマシンの速度と品質に達すると、3人以上が必要になります。一人当たり月給 5,000 元、年間 10 か月の勤務とすると、3*5000*10=150000 となります。首都は巨大です。

- 外観比較: 通常のグリルの外観は長年にわたって革新的ではありませんでした。このバーベキューマシンのデザインは斬新で興味深く、特定の装飾的な特徴を備えており、新しいものに対する消費者の好奇心を大いに満たすことができます。利用する加盟店にとっては良い宣伝効果が期待できます。

チェーンタイプのバーベキューマシングリルパラメータ:

- 機械サイズ: 1000*1600*600mm。

- 機械重量: 75KG。

- 電圧: 120

- 焼き時間:10〜20分(焼き材料が異なると必要な時間も異なります)。

- 生産: 500-800秒

これに関連する機械: ケバブスキュア機