자외선은 박테리아를 죽일 수 있으며 특정 발암 능력을 가지고 있습니다. 그렇다면 UV 살균기로 처리된 음식을 먹을 수 있을까요?

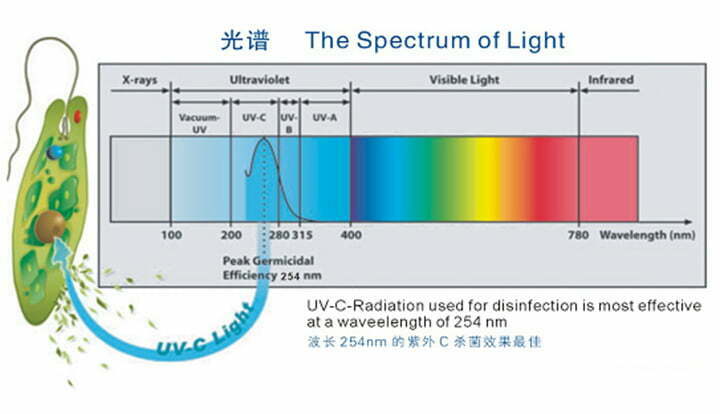

자외선은 10nm에서 400nm 사이의 파장을 갖는 전자기 방사선으로 정의됩니다. 그러나 실제 응용 분야에서 사용되는 파장은 일반적으로 100나노미터 이상입니다. 315~409나노미터 사이의 파장을 갖는 UVA는 일반적으로 피부를 태닝합니다. 280~315나노미터 파장의 UVB는 피부에 화상을 입히고 피부암 발병 위험을 높일 수 있다. 200~280nm 파장의 UVC는 박테리아와 바이러스를 효과적으로 죽일 수 있습니다. 100~200nm 파장의 자외선은 공기 중의 산소에 흡수됩니다. 따라서 기존의 자외선 살균은 254나노미터의 파장을 사용한다.

자외선이 박테리아나 바이러스에 흡수되면 DNA가 손상되어 증식 능력을 잃게 될 수 있습니다. 살균 결과는 가열하거나 약품으로 처리하는 것과 동일합니다. 그러나 자외선에 의한 살균방식은 가열하지 않고도 영양성분을 파괴하지 않는다. DNA는 음식의 영양소가 아니며 신체에 필요한 분자가 파괴되지 않기 때문입니다. 또한, 음식 본연의 맛을 파괴하지 않습니다. 결국 화학 살균제나 방부제는 새로운 물질을 도입하고 때로는 "냄새"를 가져옵니다. 자외선에 의해 파괴된 DNA 분자는 유해물질을 생성하지 않고 인체 내에서 분해됩니다.

따라서 자외선의 발암성에도 불구하고 자외선 처리 식품은 안전성 문제가 없다.

모든 식품 가공 방법은 식품에 어느 정도 "손상"을 가져옵니다. 가장 일반적인 가열에 비해 UV 처리의 손상은 훨씬 적습니다. 과일 주스와 같이 "천연" 상태를 유지하려는 일부 식품의 경우 이는 큰 이점이 있습니다.

UV 살균 능력은 파장뿐만 아니라 식품이 조사되는 에너지에 따라 달라집니다. 에너지가 낮을수록 살균효과가 떨어집니다. 선택된 파장 254 nm에서는 살균 효과와 에너지 세기가 늘어난 S자 모양을 나타냅니다.

가열이나 화학살균제에 의한 완전살균 등 자외선 살균은 어렵다. 일반적으로 4개의 로그가 감소하는 것이 "살균 표준"으로 사용됩니다. 즉, 박테리아 10,000개 중 1개가 생존합니다. 섭씨 72도에서 15초 동안 처리된 신선한 우유의 저온살균은 일반적으로 5로그만큼 감소합니다. 이는 최대 100,000개의 박테리아 중 1마리만 생존한다는 의미입니다. 상온에서 우유를 초고온 살균하는 경우 감소된 로그 값이 12 이상이고 박테리아가 거의 생존할 수 없습니다.

미생물마다 자외선에 대한 민감도가 다르며, 그 중 일부는 낮은 에너지 강도에서 대량으로 죽는 반면, 다른 미생물은 더 높은 에너지를 필요로 합니다. 4개의 로그 값을 표준으로 감소시키면 연구에서 발견된 박테리아 중 일부는 평방 미터당 에너지가 수십 줄만 필요한 반면 다른 박테리아는 평방 미터당 300줄 이상의 에너지가 필요했습니다. 우리는 음식에 어떤 박테리아가 있는지, 얼마나 많은지 모르기 때문에 항상 가장 끈질긴 박테리아를 목표로 삼고 다른 박테리아는 파괴합니다. 따라서 UV 살균을 위한 에너지 강도는 평방미터당 400줄 이상이어야 합니다.

현재 식품 산업에서 UV 살균의 주된 응용 유형은 세 가지입니다:

첫 번째는 식품 운반선이나 식품 생산 장비의 소독입니다. 담체나 장비의 경우 미생물이 항상 표면에 머물게 되며, UV 투과율이 떨어지는 약점은 무관합니다. 가열하지 않고 다른 물질(물 포함)을 도입하지 않는 장점이 충분히 활용됩니다.

두 번째는 식품가공수의 전처리이다. 염소나 염화물을 첨가하는 '화학적 수단'에 비해, 화학물질을 투입하지 않는 UV 살균은 살균 부산물과 살균제로 인한 냄새의 위험을 피할 수 있습니다.

셋째, 현재 자외선으로 직접 살균하는 주요 식품은 과일주스이다. 과일 주스는 가열하면 맛이 쉽게 변하기 때문에 과일 주스 제조에는 '비열 처리'가 매력적입니다. 살균제라는 이름 때문에 소비자들이 싫어하게 되기 때문에 맛이 변하지 않고 '화학성분'이 들어가지 않는 자외선 살균이 활용도가 높다.