자동 채소 다지기 기계는 복합 칼날로 설계되어 뿌리 채소(감자, 당근, 죽순 등)를 ±0.1mm 등급의 정밀한 큐브/직사각형으로 성형할 수 있습니다.

시간당 2000kg의 초고용량을 실현할 수 있으며, 매끄러운 절단면과 높은 성형률을 가진 완제품을 생산합니다. 본체는 알루미늄-마그네슘 합금과 식품 등급 스테인리스 스틸로 제작되어 아름답고 내식성이 뛰어나며, 엄격한 위생 기준을 충족합니다.

절단 크기는 3-100mm로 조정 가능합니다. 빠른 냉동, 탈수 또는 마리네이드 생산 라인에서 사용되든, 낮은 에너지 소비, 높은 효율성 및 쉬운 조작 덕분에 귀하의 공장에 더 안정적이고 높은 수율의 주사위 절단 솔루션을 제공합니다.

채소 절단 기계의 매개변수

- 생산 능력: 1000KG/H

- 모터 모델 및 전력: Y802-4, 380V/0.75kW

- 크기 : 710X 660X 1085mm (길이 x 너비 x 높이)

- 기계 중량: 100kg

- 채소 절단 사양: 4, 5, 6, 8, 10, 12, 15mm의 정육면체 또는 직육면체로 자르거나 요구 사항에 따라 다른 크기의 도구를 만듭니다.

야채 다이싱 기계는 어떻게 작동합니까?

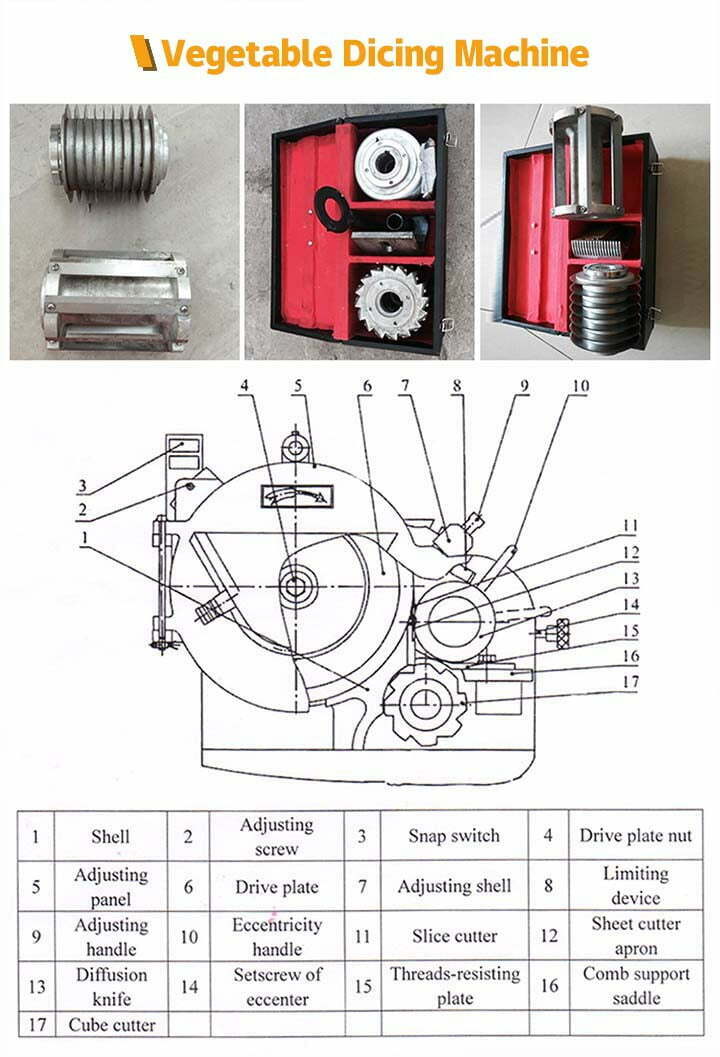

구조적 특징

- 프레임과 외관: 부식 저항을 보장하고 청소가 용이하며 위생 기준을 충족하기 위해 알루미늄-마그네슘 합금과 식품 등급 스테인리스 스틸로 제작되었습니다.

- 급지 호퍼: 경사진 입구 디자인으로 배치된 채소가 고르게 배출되기 쉽습니다.

- 다이얼(턴테이블): 다이얼 커버와 결합되어 모터에 의해 고속 회전이 가능합니다.

- 수직 절단기 조립체: 케이스 내부에 고정 장착되어 있으며, 채소를 방사 방향으로 얇게 자르는 데 사용됩니다.

- 디스크 절단기: 여러 개의 원형 강선이 장착되어 있으며, 얇은 조각을 균일한 스트립으로 자르는 데 사용됩니다.

- 수평 절단기 조립체: 다이얼 아래에 수평으로 배치되어 채소 스트립을 원하는 정육면체나 큐브로 자릅니다.

- 전송 시스템: 모터 + 벨트(또는 기어) + 다이얼 샤프트로 회전력을 제공합니다.

- 전기 제어 시스템: 시작-정지 버튼, 비상 정지 스위치 및 선택적인 무단 속도 조절 기능을 포함합니다.

작동 원리(다섯 단계)

- 채소는 급지 호퍼에서 회전하는 다이얼로 미끄러져 들어가며, 새틴 홈이나 탭을 통해 채소를 고르게 정렬합니다.

- 다이얼이 고속으로 회전할 때, 채소는 원심력의 작용으로 수직 절단기에 달라붙어 즉시 균일한 두께의 조각으로 잘립니다.

- 슬라이스는 계속 다이얼에서 움직이며, 여러 개의 와이어가 동시에 슬라이스를 동일한 너비의 스트립으로 나누는 디스크 줄리엔 커터를 통과합니다.

- 채소 조각이 중력이나 유도 장치에 의해 가로 절단기 영역으로 떨어져 가로 절단기에 의해 잘려 균일한 크기의 다이스 또는 직사각형 조각이 만들어집니다.

- 다진 채소는 기계의 끝에서 자동으로 배출되며 다음 공정(예: 급속 냉동, 탈수 또는 마리네이드)에 직접 전달될 수 있습니다.

절단할 재료는 채소 다지기 기계를 사용하기 전에 깨끗이 세척하고 혼합하는 것이 중요합니다. 절단할 재료가 모래와 흙과 섞여 있다면, 날의 가장자리와 날이 쉽게 손상되고 무뎌질 수 있습니다. 재료의 최대 절단 직경은 80mm를 초과해서는 안 됩니다.

채소 다지기 기계의 주요 장점

- 복합 공구 설계는 "수직 칼→파쇄→수평 칼"의 3단계 처리를 실현하며, 여러 번의 과급 없이 한 번에 완료할 수 있습니다.

- 부드러운 절단면, 균일한 크기의 큐브/직사각형, 높은 수율, 급속 냉동, 탈수 및 절임과 같은 후속 공정의 요구 사항을 충족합니다.

- 모터가 다이얼 + 칼 세트를 직접 구동하며, 에너지 소비가 낮고 속도가 안정적이며, 절단 효율은 시간당 수천 킬로그램에 이를 수 있습니다.

- 채소 다지기 기계 본체, 급지 호퍼 및 모든 접촉 부품은 알루미늄-마그네슘 합금과 스테인리스 스틸로 제작되어 내식성이 뛰어나고 청소가 용이하며 건강 기준에 부합합니다.

- 콤팩트한 구조, 빠른 분해 및 조립, 전문 도구 없이 속도 조절 및 칼날 교체, 낮은 일일 유지 관리 비용.

결함 분석 및 문제 해결

| 결함 현상 | 원인 분석 | 제외 방법 |

| 야채 슬라이서 기계의 낮은 작업 효율성 | 일반 V벨트는 작업 중 느슨하고 미끄럽습니다. | 일반 V밴드를 조여주세요. |

| 재료가 떨어지지 않음 | 1. 빗 칼날과 스페이서 링 사이의 거리가 너무 큽니다. 2. 슬라이스 두께가 너무 두껍습니다. | 1. 빗이 분리 링 표면에 가깝도록 빗의 위치를 다시 조정하십시오. 2. 슬라이스 두께가 빗의 위치와 일치하도록 슬라이스 두께를 조정합니다. |

| 절단되지 않은 재료 | 1. 디스크의 회전 방향이 지정된 방향과 일치하지 않습니다.

2. 빗이 막혔습니다. 3. 디스크 절단 도구가 작동 중에 느슨해졌습니다. 4. 수직 칼날이 재료에 의해 막혔습니다. | 1. 회전 휠을 시계 방향으로 조정합니다.

2. 빗을 청소하세요. 3. 디스크 절삭 공구 조합을 고정합니다. 4. 세로칼로 남은 음식을 정리해주세요 |

| 섬유 재료를 절단할 때, 절단의 일정한 현상이 발생합니다. | 1. 디스크 커터가 수직 커터의 플레이트 홈에 있지 않습니다. 2. 디스크 커터의 심각한 마모. | 1. 디스크 절단 도구 조합이 플레이트 홈에 약 1mm 위치하도록 조정하십시오. 2. 원형커터가 정상인지 심하게 마모되었는지 확인 후 연삭 또는 교체하십시오. |

저희 채소 다이스 기계는 이미 바타와나(Botswana), 필리핀, 미국, 멕시코, 캐나다 및 기타 국가로 성공적으로 수출되었습니다. 또한 저희 공장에서는 다기능 채소 절단 기계와 같은 과일 및 채소 가공 전반의 장비를 제공하며, 세척, 절단, 살균의 전체 공정을 포괄합니다. 더 자세한 제품 정보를 보시려면 저희 웹사이트를 둘러보시거나 온라인으로 메시지를 남겨주시면, 저희 전문 팀이 최적의 솔루션을 추천해 드립니다!