Vegetable dicing machine is used in dehydrated vegetable, quick-frozen vegetable processing plant and food pickle industry to process various root and stem vegetables into cube and cuboid shapes. The machine uses a composite tool. When cutting vegetables, it can be formed at one time, with regular shape, smooth cut surface and high forming rate, which is favored by foreign customers. The machine is advanced in design, convenient in operation, low in energy consumption and high in work efficiency. It is made of aluminum-magnesium alloy and stainless steel material, which is anti-corrosion, beautiful and meets the sanitary standard.

How does the vegetable dicing machine work?

Structural features:

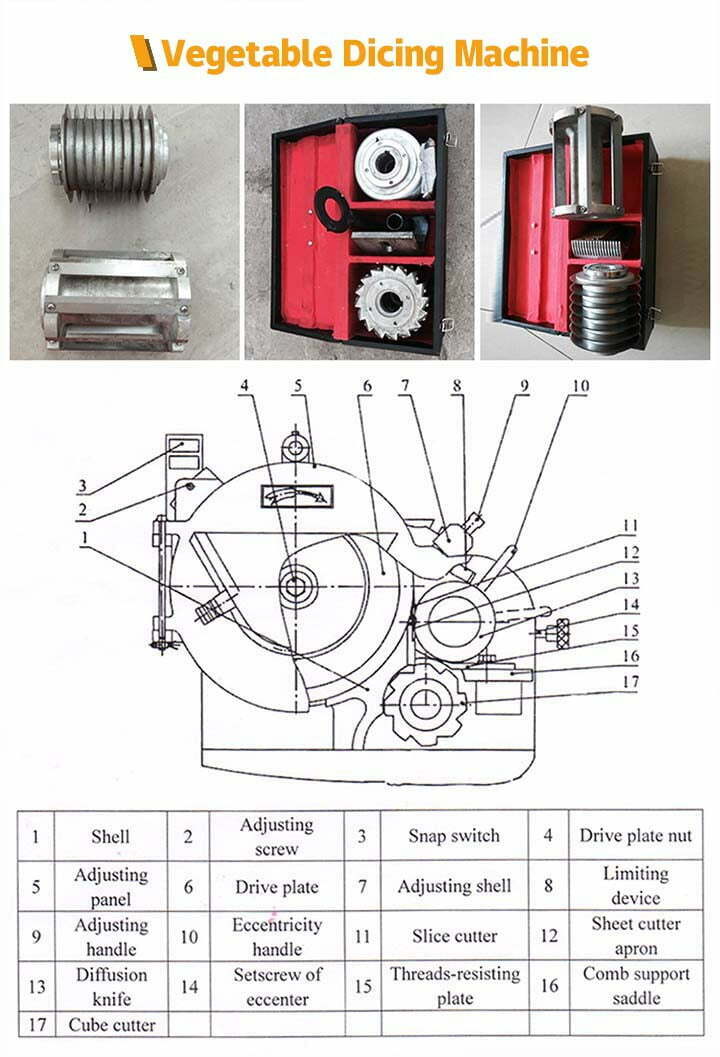

The vegetable slicing machine mainly consists of a base, a shell, a dial, a vertical knife, a screwdriver body, a transverse cutter body, a transmission system, and an electrical control system. The machine base, casing, hopper, and main components are made of aluminum-magnesium alloy and stainless steel to ensure long-term work without rust and poison. In our company, we also have another vegetable cutting machine for sale.

Working Principle:

The machine’s dial drives the object to rotate at high speed, uses centrifugal force of the object, cuts the object into slices with vertical knife, then cuts the object into strips with circular wire cutter, and feeds the cut material into the cross cutting edge, and cuts the cube or cuboid needed by the cross-cutting knife.

Parameter of the vegetable cutting Machine:

- Production capacity: 1000KG/H

- Cut vegetable specifications: Cut cubes or cuboids of 4, 5, 6, 8, 10, 12, and 15mm, or make other sizes of tools according to requirements.

- Motor model and power: Y802-4, 380V/0.75kW

- Dimensions: 710X 660X 1085mm (length x width x height)

- Machine weight: 100kg

Model explanation of vegetable dicing machine:

C HD 100

“100” means that the cutting ability is 1000kg/h (when the dicing size is 15m cube).

“HD” means a rotary cutter with multiple cutting functions.

“C” stands for the first Chinese phonetic alphabet of “vegetable” in the “cutting machine”.

Preparation and inspection before using the vegetable dicing machine:

- Fix the screw of the hopper at the inlet and outlet of the shell (to facilitate packaging and transportation, the hopper is removed).

- Check if there is any foreign matter in the casing, and remove the foreign matter in the casing, otherwise the blade may be damaged.

- Clean up the operation site, check whether the power supply voltage is consistent with the local voltage, and connect the ground wire reliably at the grounding mark. Close the switch and press the “on” button to check whether the steering is correct (face up to the turntable, clockwise direction is correct), otherwise, cut off the power supply and adjust the wiring.

- Connect the water source for use.

- When the vegetable dicing machine is working, do not put hands and other foreign bodies into the shell, in order to avoid danger.

Precautions of vegetable dicer:

- First, the material to be cut should be washed and mixed. If the material to be cut is mixed with sand and mud, the blade edge and the blade are easily damaged and blunt. The maximum cutting diameter of the material should not exceed 80mm. If it is larger than this diameter, it should be cut into small pieces.

- Close the switch, close the shell door, press the safety switch. When the shell door is not closed in place, can not press the switch, otherwise the line is blocked, the motor can not run.

- The cutting material is put into the shell from the hopper. Under the action of the dial, it is cut into the required thickness by the vertical cutter, then cut into strips by the disc cutter, and finally cut into squares by the transverse cutter.

- Adjustment of the dicing machine specification: It is changed by adjusting the slice thickness and replacing the disc cutter and the cross cutter.

Fault analysis and troubleshooting:

| Fault phenomenon | Cause Analysis | Exclusion method |

| Low work efficiency of vegetable slicer machine | Ordinary V-belt is loose and slippery at work | Tighten common V-band |

| Material not falling | 1. The distance between the comb knife-edge and spacer ring is too large.

2. Slice thickness is too thick | 1. Re-adjust the position of the comb so that the comb is close to the surface of the separator ring.

2. Adjust the slice thickness so that the slice thickness is consistent with the position of the comb. |

| Material not cut | 1. The rotation direction of the disc is not in accordance with the specified direction.

2. Blockage of the comb. 3. Disk cutting tool is loosened in operation. 4. The vertical knife is blocked by material. | 1. Adjust the turning wheel to clockwise direction.

2. Clean the comb. 3. Fastening disc cutting tool combination. 4. Clean up the leftovers at the vertical knife |

| When cutting fiber materials, there is a constant phenomenon of cutting | 1. The disc cutter is not in the plate groove of the vertical cutter.

2. Serious wear of disc cutter | 1. Adjust the disc cutting tool combination so that it is located in the plate groove about 1 mm.

2. Check whether the round cutter is normal or worn seriously, and then grind or replace it. |

Maintenance of the dicing machine:

All maintenance and maintenance work must be done after the power has been switched off.

- The vegetable cutting machine must be cleaned after each use, especially where the material passes and the passage.

- After each use, carefully check whether all cutting tools are damaged or blunt, check whether the comb blade is normal or damaged. Dismantle the disc cutting tool and the cross-cutting tool once a week (be careful when disassembling, use special tools to avoid injuring hands). And proper cleaning. When reassembling, it must be maintained with non-toxic and tasteless food oil. Before installation, food oil must be applied on the cutting shaft and cutting shaft to ensure its disassembly convenience.

- Oil the gears and chains every two weeks.

- Grinding all kinds of cutters on time to ensure their sharpness.

Transportation and storage:

- In the process of using the vegetable dicing machine, it is strictly forbidden to bump, tilt and invert, so as to avoid damaging the machine and affecting its use.

- When the product is not used for a long time, it should be stored in a dry, non-corrosive gas environment. Do not contact the corrosive substance, so as to avoid damage to the vegetable cutter machine.