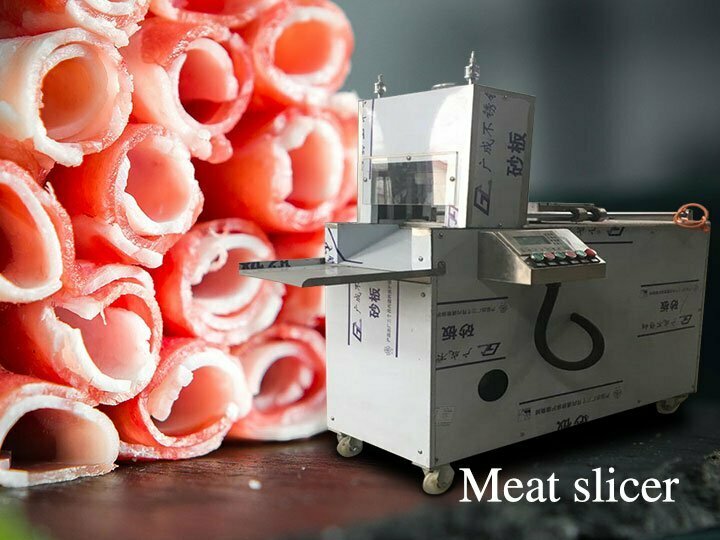

The frozen meat slicer, also known as a beef and mutton roll cutting machine, is a type of machine used for cutting frozen meat, specifically for making beef and lamb rolls. This is a highly efficient automated meat processing equipment specifically designed for cutting lamb, beef, and other elastic frozen meats.

This machine can process 1, 2, 4, or 8 rolls of meat at once. Operated via an intelligent PLC control panel, it automatically completes slicing and rolling with uniform thickness, significantly boosting production efficiency and reducing labor costs.

Whether in hot pot restaurants, hotels, or large food processing plants, the beef and lamb roll cutter ensures visually appealing meat rolls with neat, hygienic, and safe slices.

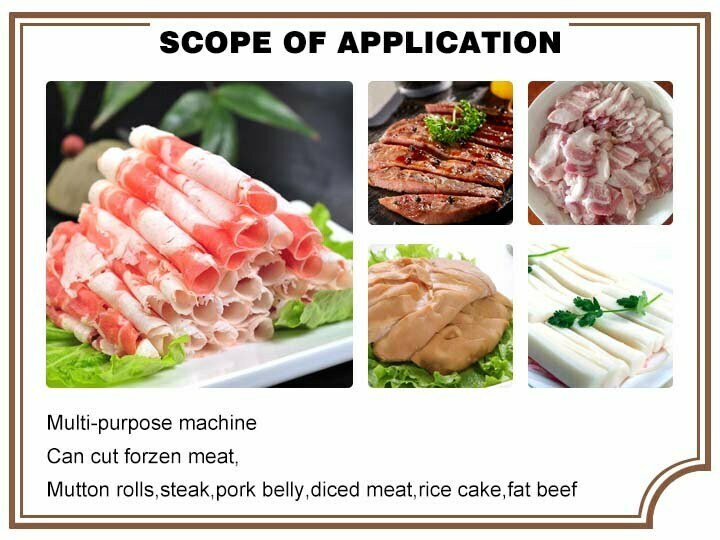

Beef and lamb rolling machine applications

- Suitable for slicing and rolling boneless, elastic meats including lamb, beef, and pork belly.

- Processes various frozen meat products to meet the diverse needs of hot pot restaurants, hotels, large food processing enterprises, and the catering industry.

- Widely used in bulk meat production and processing for uniform cutting, rolling, and efficient manufacturing.

Advantages of frozen meat slicer

- Uniform slicing, neat rolling: automatic rolling ensures consistent thickness per roll with minimal material waste.

- High efficiency and energy savings: automated operation reduces labor intensity and increases processing speed.

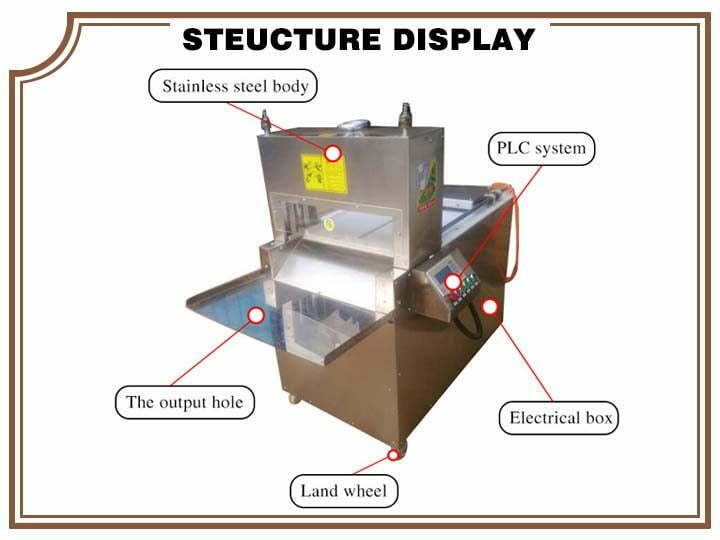

- Hygienic and safe: constructed with 304 stainless steel and equipped with transparent safety guards, preventing hand contact during cutting and meeting food hygiene standards.

- Low-noise and stable: smooth operation with minimal noise, featuring a robust and reliable structure.

- Easy maintenance: fully hydraulic operation ensures low failure rates, with easily removable and cleanable blades.

- Flexible operation: supports both manual and remote control, allowing adjustment of slice thickness and speed according to production needs.

- Safety design: anti-slip U-shaped meat tray and optimally selected blade combs ensure thorough cutting without residue and safe operation.

How to use frozen meat slicers?

- Dual-directional advancement system: automatically pushes and compresses meat while adjusting slice thickness.

- Auto-cut stop: blade automatically stops after cutting completion, with pusher plate retracting.

- Synchronized operation: cutting blade and conveyor belt operate in unison to ensure uniform slices; entire machine automatically powers down when safety door is opened.

- Rolling and conveying: sliced meat rolls are automatically formed and efficiently conveyed via the system, ideal for high-volume production.

Precautions for using beef and lamb slicers

- Meat requirements: meat must be moderately frozen with appropriate firmness, generally above -6°C. If meat is excessively hard, partially thaw it first.

- Deboning: meat must be bone-free to prevent blade damage.

- Loading sequence: place meat first, then adjust desired slice thickness via control buttons.

- Blade inspection: if blades slip or fail to secure meat, rust may be present. Sharpen promptly.

- Model selection: choose the appropriate model based on output requirements:

- Electronic single-roll slicer: output 25-50 kg/h

CNC four-roll slicer: output 250-300 kg/h

CNC eight-roll slicer: output 450-500 kg/h - Packaging and shipping: the entire machine is packed in a wooden crate to ensure safe transportation.

Parameters of the frozen meat slicer

| Name | Power(kW) | Voltage(v) | Production(kg/h) | Slice thickness(mm) | Machine weight(kg) | Machine size(mm) |

| one roll slicer | 0.45 | 220 | 25-50 | 0.2-5 | 50 | 650*350*400 |

| four roll slicer | 1.5-3.5 | 220/380 | 250-300 | 0.2-20 | 300 | 1450*660*1300 |

| eight roll slicer | 3.5 | 380 | 450-500 | 0.2-20 | 400 | 1450*1010*1450 |

Working video of frozen meat slicer

If you’re seeking an efficient, reliable, and easy-to-operate beef and lamb slicer, we offer suitable models for both small eateries and large-scale food processing enterprises.

We also provide other meat cutting machine. Contact us today for a professional solution that will make your meat processing faster, more hygienic, and labor-saving—boosting production efficiency and product quality!