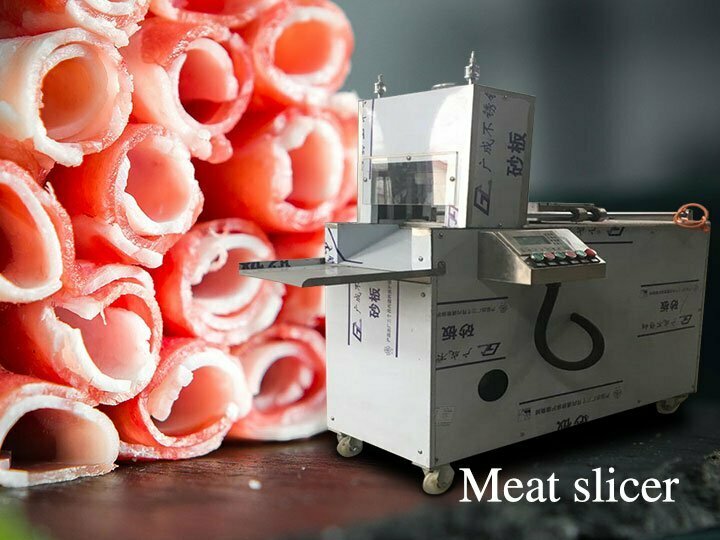

The frozen meat slicer is suitable for slicing frozen boneless meat, and other similar elastic foods. Traditional manual meat slicing not only has low production efficiency but also has different quality and uneven thickness. The appearance of the hot pot meat slicer perfectly solves this problem. While improving work efficiency, it also frees people’s hands and saves labor costs. It is widely used in hot pot restaurants, dining halls, hotels, and food processing workshops. It has a uniform meat cutting effect and is particularly stable and durable.

Introduction of Frozen Meat Slicer

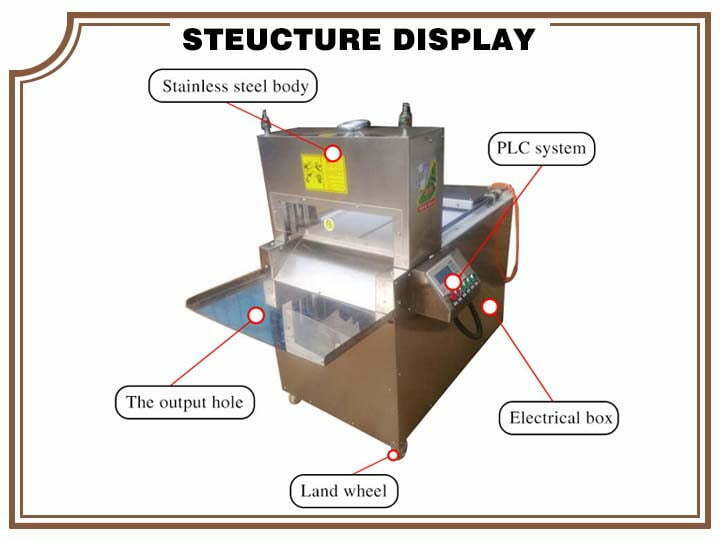

The meat slicing machine is made up of eight parts: a pressing handle, oil cup, operation panel, cutter, cutter shaft, electrical integration box, pushing device, and sliding rail.

Before starting to slice, first, debug the machine, familiarize yourself with the various buttons on the control panel and drop some cooking oil into the sliding track to reduce friction. After adjusting, press the start button to move the blade to the bottom, and put the material into the sliding track so that it is just against the blade. Then rotate the pressing handle, and press the forward button after pressing the meat. After the nails on the pusher are inserted into the meat, press the stop button, adjust to the appropriate slice thickness and press the start button. Finally, meat rolls are made evenly in thickness. If you need meat cutting machine, you can also contact us.

Advantages of Frozen Meat Slicer

- Slice thickness is balanced, with a good automatic rolling effect. The loss of raw materials is reduced to the greatest extent. In the process of processing, it avoids touching by hand and improves the cleanliness and hygiene of products.

- The noise of the machine is low and the stability of the whole machine is excellent.

- The fuselage is 304 stainless steel, which meets the requirements of food hygiene.

- The full hydraulic operation, low failure rate, easy maintenance, and simple structure.

- Strong adaptability, with remote control and manual operation control mode, simple and convenient, time-saving and labor-saving.

- U-shaped meat dish, more stable, non-skid.

- Choose carefully the knife comb, the meat will not stay on the knife. In addition, the machine cutter is easy to disassemble and clean.

- Place a transparent safety baffle in the cutting area to prevent injury.

How to Use Frozen Meat slicers?

1. Meat must be moderately frozen and hardened, generally above “-6 °C”. If the meat is too hard, it should be thawed first.

2. Do not contain bones in the meat to avoid damage to the blade.

3. Place the meat first, and then adjust the button to set the desired thickness.

4. If the knife slips or can not hold the meat, indicating that the knife has rusted, and it should be sharpened.

Particular attention:

- We have three types of machines for you to choose from: electronically controlled one-roll slicer, CNC four-roll slicer, and CNC eight-roll slicer. The corresponding output is 25-50kg /H, 250-300kg /H and 450-500kg /H respectively. If your company’s output is small, you can buy an electric control roll slicer. If your output is large, you can consider the latter two models.

- In the aspect of packaging and transportation, the whole wooden box packing can completely relieve the transportation safety of the machine.

Parameter of the Frozen Meat Slicer

| Name | Power() | Voltage(v) | Production(kg/h) | Slice thickness(mm) | Machine weight(kg) | Machine size(mm) |

| one roll slicer | 0.45 | 220 | 25-50 | 0.2-5 | 50 | 650*350*400 |

| four roll slicer | 1.5-3.5 | 220/380 | 250-300 | 0.2-20 | 300 | 1450*660*1300 |

| eight roll slicer | 3.5 | 380 | 450-500 | 0.2-20 | 400 | 1450*1010*1450 |