TP series peanut skin removing machine is the ideal equipment for removing peanut red coat. The peeling rate is over 97%, and it is one of the necessary machines for deep processing of peanut. The reason why it is called dry peeling machine is that the peanuts peeled off with this machine do not need to be soaked. Baked peanuts (water content less than 5%) can be directly put into the machine for peeling treatment. Short consumption time and high work efficiency.

How does peanut skin removing machine work?

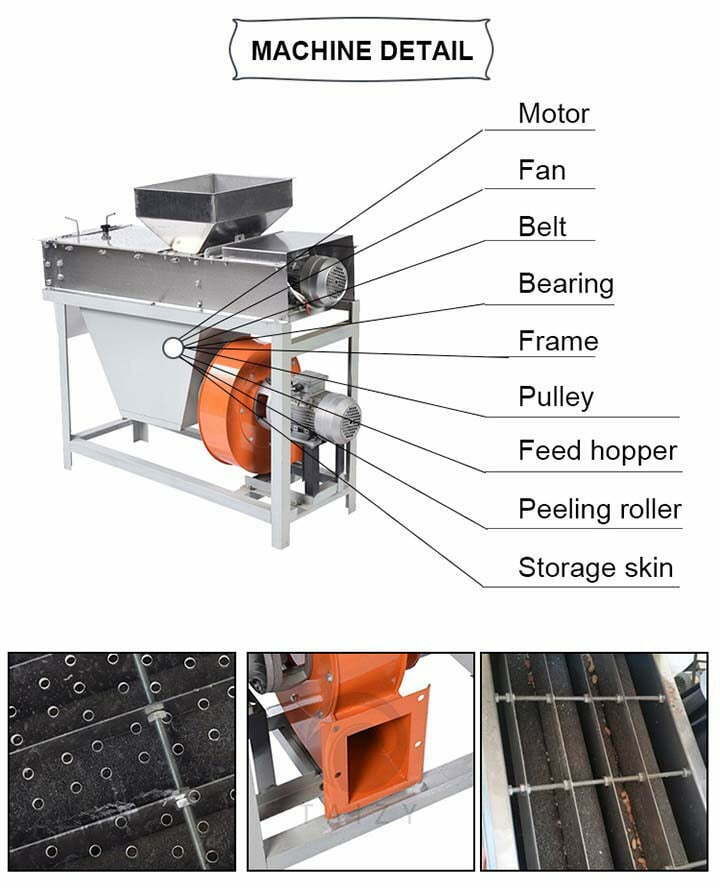

The peanut peeler machine is composed of a power device (including a motor, a pulley, a belt, a bearing, etc.), a frame, a feeding hopper, a peeling roller (a steel roller or a diamond roller), a fan, and the like.

The peanut dry peeling machine adopts the working principle of differential rolling friction transmission and peels when the moisture of peanuts is less than 5 percent (to avoid baking paste) after baking. First, the peanuts are put into the peanut skin removing machine through the feeding hopper. The skin and peanut kernels will be separated quickly after the peanut is rubbed by the peeling roller. The fan system will absorb the separated peanut skin, and the nuts will be screened by vibrating screen to separate the whole peanut kernel, half peanut kernel, and broken peanut.

Technical parameters of peanut skin removing machine:

| Type | TP-1 | TP-2 | Tp-3 | Tp-4 |

| Output | 200-300kg/h | 400-500kg/h | 600-800kg/h | 800-1000kg/h |

| Motor power | 0.55kw | 0.55kw*2 | 0.55kw*3 | 0.55kw*4 |

| Fan power | 0.37kw | |||

| Voltage and Frequency | 380V/220V 50HZ | |||

| Peeling rate | Over 98% | |||

| Size (MM) | 1100*400*1100 | 1100*700*1100 | 1100*1000*1100 | 1100*1400*1100 |

The above are the parameters of four peanut red skin peeling machines. No matter which machine you choose, the peeling rate is more than 98%. Our largest machine is 1000 kg / h and the smallest is 200 kg / h. The choice of machine depends on the size of your factory and your specific needs.

Peanut skin removing machine features:

- The peeling effect is good. The peanut skin removing machine contains two sets of peeling rolls. The two sets of peeling rolls are relatively frictional, and the peeling rate can reach over 97%.

- Peanut half grain rate is low. This machine replaces the traditional combat peeling method with the friction peeling method. While reducing the half-grain rate of peanuts, the breakage rate of peanut kernels is also greatly reduced.

- The peeling quality is good. The peeled peanuts are not broken and the nuts remain intact. Using physical peeling, the color is white and the protein is invariant.

- Reasonable design. This peanut peeling machine adopts the new peeling principle and peeling components and has the characteristics of small volume, low energy consumption, high work efficiency, and convenient operation.

- Wide range of applications. It is suitable for peeling peanuts, almonds, cashew nuts and other materials. It can be used for pre-processing of fried peanuts, peanut pastries, peanut sugar, peanut milk, peanut protein powder, and some canned foods.

Common faults and treatment methods:

| Common faults | Causes | Method of exclusion |

| Low peeling rate | Peanut has a high moisture content | Reduce water content to about 5% |

| High breaking rate | Overfeeding | Controlling feeding |

| The peeling roller working surface is uneven | Repair the surface of the peeling roller or replace the peeling roller | |

| Peanut has a low moisture content | Appropriate increase in moisture | |

| Peanut kernel mixed with a small amount of peanut skin | Material blockage at the outlet | Discharge material |

| Blockage of the fan outlet | Check for debris in the blades, clean up debris | |

| The excreted peanut skin is mixed with peanut kernels | The wind speed of the fan is too high or the wind force is too high. | Appropriate adjustment of wind power |

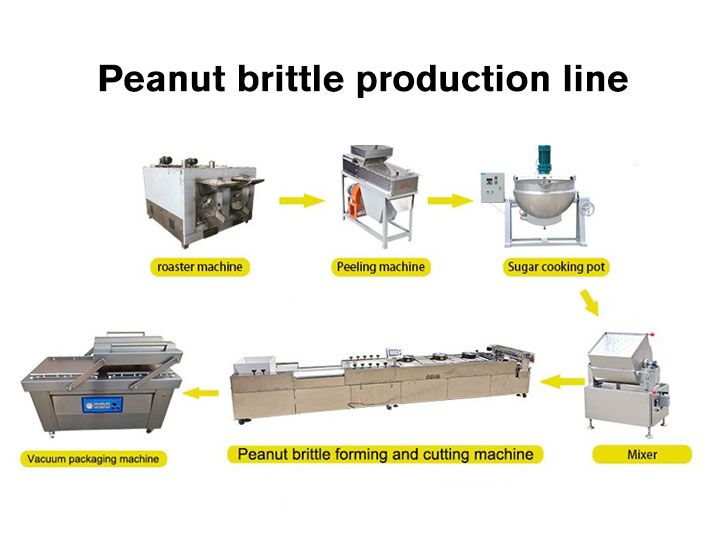

Related production line:

peanut brittle production line