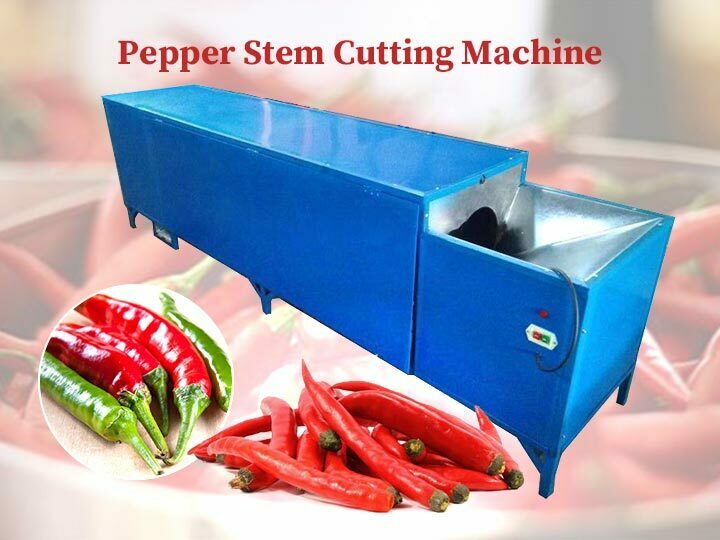

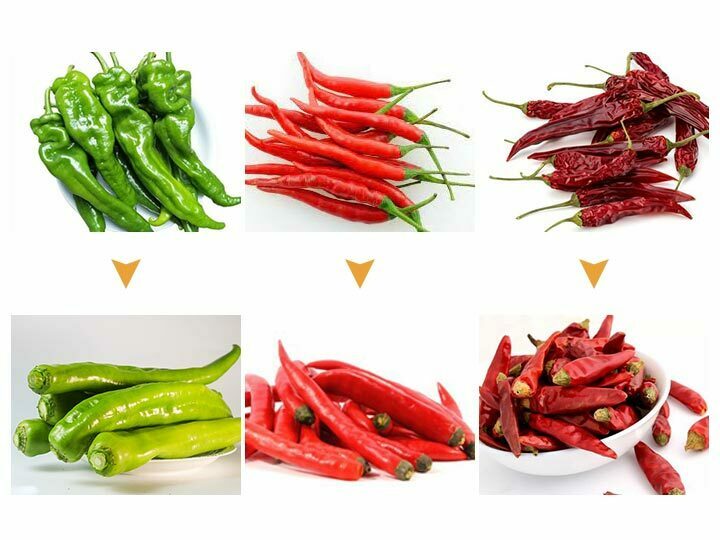

Our fully automatic pepper stem cutting machine can quickly and accurately remove the stems or tails of fresh peppers, dried peppers, and peppers of different varieties and sizes.

In the field of pepper processing, manual stem removal is not only inefficient (the average daily processing volume is less than 50 kg), but also causes burns to the operator’s hands due to capsaicin stimulation, which has become a pain point restricting industrial upgrading.

This pepper stem cutting machine only requires one person to operate to achieve a stem removal rate of more than 95%, and the processing speed can reach up to 2000 kg/hour, which is 10-15 times the efficiency of manual labor.

Core advantages of pepper stem cutting machine

- Precision knives and intelligent drop design, the incision is smooth and no residue, greatly reducing the damage to the pulp.

- The machine body is fully enclosed and equipped with exhaust gas discharge port to ensure no dust spillage during the cutting process.

- Automatic sorting technology realizes efficient separation of finished products and waste materials to ensure the quality of subsequent processing.

- The spacing and cutting angle of the knife plate can be adjusted quickly, suitable for different varieties, sizes and humidity of fresh and dried chili peppers.

- The output of a single pepper stem cutting machine is more than 5 times of the similar products in the market, and the daily output can be up to several tons, which obviously shortens the processing cycle.

Chili stem remover application scope and scenarios

The pepper stem cutting machine supports precise cutting of different sizes of peppers through a modular design (1-10cm adjustment range). It can be adapted to the market mainstream varieties such as chaotian pepper, millet pepper, line pepper, bell pepper, wild san pepper, and so on. The machine is widely used in the following work scenarios:

- Small, medium and large farms, agricultural cooperatives: preliminary sorting and de-stemming of fresh and dried peppers, reducing the intensity of manual operation.

- Pepper deep-processing plants (chili powder, chili oil, sauce production): automated assembly line front-end de-stalking link to ensure product quality and consistency of downstream drying, crushing, leaching and other processes.

- Central kitchen, prefabricated vegetable production line: provide shanked and cleaned chili pepper raw materials for restaurant chains or frozen food to ensure food safety and hygiene standards.

- Wholesale market, cold chain storage: sorting and pre-processing of large quantities of fresh/dried peppers to provide qualified sources for distributors or exporters.

Chili destemming machine working principle

- Chili peppers are uniformly fed into the feed hopper by hand or conveyor, and are neatly arranged by vibration device or guiding groove.

- Driven by the frequency conversion motor, the double knife discs rotate at high speed against each other, and the knife blades accurately wrap the roots of pepper stalks to realize rapid cutting.

- The cut off stalks are guided into the collection port, while the complete fruits slide down to the discharge port by gravity, and the whole process is continuous.

- After removing the stalks, the peppers are neat and clean, which is convenient for subsequent air-drying, baking or packaging, and maintains the bright color and pure flavor of the fruits.

Parameters of the pepper destemming machine

| Type | Voltage | Power | Size | Weight | Material | Capacity of fresh chili | Capacity of dry chili |

| TZ-50-2A | 220v 50hz,1 phase | 3kw | 2860*590*1360mm | 238kg | carbon steel | 250kg/h | 120kg/h |

| TZ-50-2S | 220v 50hz,1 phase | 3kw | 2860*590*1360mm | 252kg | 304 stainless steel | 250kg/h | 120kg/h |

| TZ-50-2ALT | 220v 50hz,1 phase | 3kw | 3860*590*1360mm | 357kg | carbon steel | 330kg/h | 180kg/h |

| TZ-50-2SLT | 220v 50hz,1 phase | 3kw | 3860*590*1360mm | 362kg | 304 stainless steel | 330kg/h | 180kg/h |

| TZ-50-2ABIGS | 220v 50hz,1 phase | 4.4kw | 2860*1100*1500mm | 470kg | carbon steel | 500kg/h | 250kg/h |

| TZ-50-2SBIGS | 220v 50hz,1 phase | 4.4kw | 2860*1100*1500mm | 482kg | 304 stainless steel | 500kg/h | 250kg/h |

| TZ-70W-2ATL | 220v 50hz,1 phase | 4.4kw | 3860*680*1600mm | 476kg | carbon steel | 400kg/h | 220kg/h |

| TZ-70W-2ANF | 220v 50hz,1 phase | 4.4kw | 4860*680*1650mm | 550kg | carbon steel | 700kg/h | 350kg/h |

| TZ-50-1ATL | 220v 50hz,1 phase | 1.5kw | 3860*600*830mm | 143kg | carbon steel | 180kg/h | 90kg/h |

| TZ-50-1A | 220v 50hz,1 phase | 1.5kw | 2860*590*850mm | 95kg | carbon steel | 120kg/h | 60kg/h |

| TZ-200-2ABTL | 380v 50hz,3 phase | 6kw | 6200*860*2200mm | 1370kg | carbon steel | 900kg/h | 500kg/h |

| TZ-200-2ABIGGERS | 380v 50hz,3 phase | 8kw | 6800*1100*2700mm | 1575kg | carbon steel | 1000kg/h | 800kg/h |

| TZ-300-2ABIGGERS | 380v 50hz,3 phase | 8kw | 8200*1100*2800mm | 2100kg | carbon steel | 2000kg/h | 1000kg/h |

In addition, our company is equipped with a vegetable washing machine and a vegetable cutting machine to help your pepper processing.

Contact our professional team now to get a free trial experience and customized solutions! We also offer after-sales warranty. Please feel free to contact us for more information!