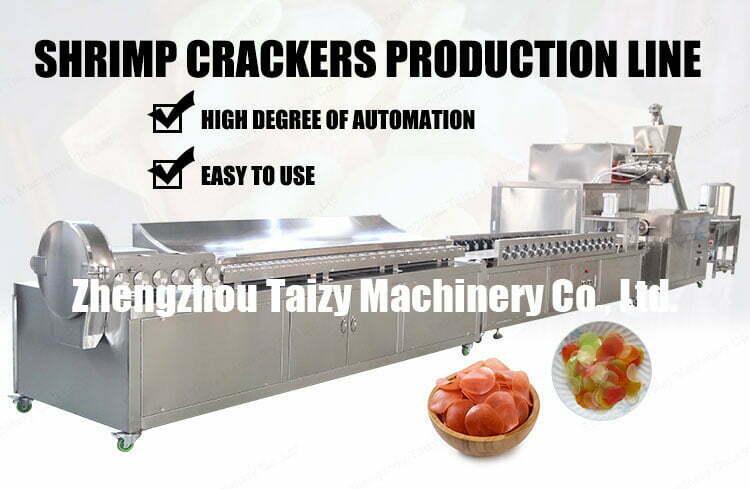

このエビクラッカー生産ラインは、Taizy食品機械のハイエンド食品生産ラインです。エビチップス生産ラインとも呼ばれます。エビクラッカー生産ラインの助けを借りて、望むエビクラッカーを非常に短時間で入手できます。ポテトとエビのスライス、エビ風味のポテトチップス、エビスティックなどとしても知られるエビクラッカー。エビ粉とデンプンで加工されたパフ菓子です。安価で美味しい味、サクサクで美味しい、栄養価の高い特性から、消費者に非常に人気があります。特にカラフルなエビクラッカーは子供たちに人気があります。

えびせんべいはどうやって作られるの?

- まず、ブレンダーを使ってエビチップスを作るための材料を混ぜます。原材料にはコーンスターチ(タピオカ粉)、エビ油、エビミール、エビペースト、 グルタミン酸ナトリウム、水など。これらの成分を均一に混合します。混合後、原料は綿状になります。この機械はエビチップスを作る最初のステップです。そして、このミキサーは、 製麺ライン.

- 次に、押出機を用いて上記混合原料を研削工具を通して押し出し、円筒状のビレットを押し出す。

この押出機は原料を熟成・混合する機能を持ち、えびせんべいの製造ラインの重要な部分です。原料をフィーダーに注入した後、スクリューの回転と押し出しによりエネルギーを発生させ、混合した原料を固化させる機械です。 - 次に、原料を成形機に供給します。成形機の主機はビレットを押し出して成形機に入ります。型に通して直径2cm~5cmのエビスティックを作ります。エビスライス押出機(前者)は、エビせんべい製造機の専用装置です。

- 次に、エビスティック切断機がエビスティックを長さ50cm〜150cmの長いエビスティックにカットします。エビスティックの長さはご要望に応じて調整できます。

- 最後にエビスティックをスライサーで厚さ0.6mm~3.5mmのエビスライスに切ります。スライサーを使用する前に、各部のボルトの緩みや刃の切れ味を確認してください。スライスする前に問題がないことを確認してください。スライスする前に、事前に刃に少量の油を塗る必要があります。お客様のニーズに応じてエビチップの厚さを調整できます。送り速度が速いため、厚みのあるエビチップスもカットできます。また、供給速度が遅いと、エビチップスを薄くスライスすることができます。

えびせんべい製造ラインの特徴

- エビせんべい機はスナック食品工場やレストランに非常に適しています。

- エビせんべい製造機はエビケーキを作ることができます。原材料にはトウモロコシ、でんぷん、小麦粉が含まれています。

- 正確な測定、高効率、材料の損傷なし。

- 安定した性能、広い応用範囲、簡単な操作性を備えた機械です。

- 切断速度に応じて、エビケーキの仕上がりが変わります。

ビスケットの形状とサイズは、円形、正方形、長方形、楕円形、またはその他の形状にカスタマイズできます。

エビせんべい加工ラインの設置と使用

- 硬化機を使用する前に、ギアボックスに 2 リットルのオイルを追加してください。

- エビせんべい製造機は平らで堅いコンクリート地面に設置してください。

- 自動エビ割り機生産ラインの部品が揃っているか、ボルトがしっかりしているかを確認してください。

- 部品の状態が良好であることを確認した後、電源を入れて 2 ~ 3 分間アイドル状態にします。他に例外がない場合は、作業を開始できます。

- 混合澱粉原料をバレル内のフィーダーに注ぎ、バレル内の温度が上昇するまで 1 ~ 2 分間運転します。次に、フィーダーの速度を調整します。

これはタイのエビせんべいの生産ラインです。ご不明な点がございましたら、お気軽にお問い合わせください。