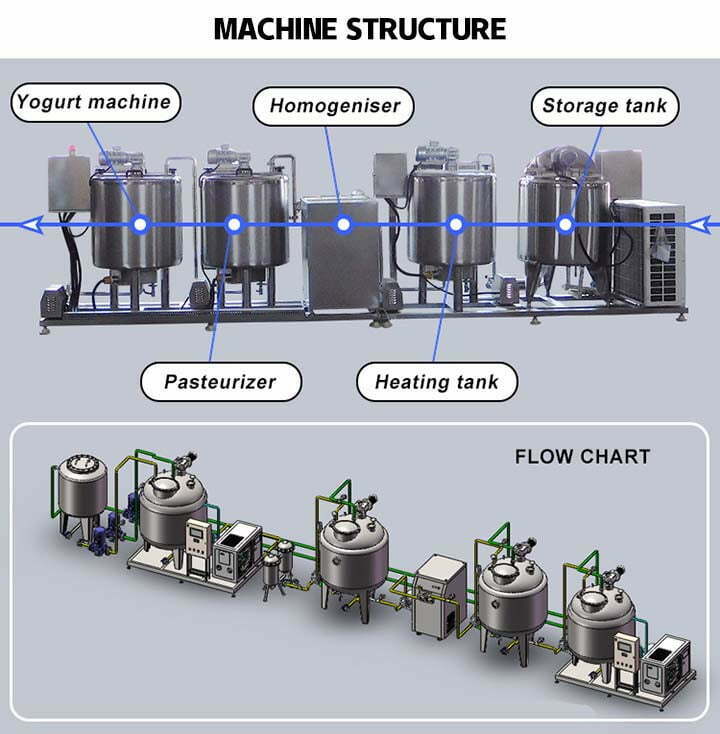

弊社が提供するヨーグルト生産設備は、国内外の高度な技術を全面的に吸収・改良したものです。小規模ヨーグルト生産ラインの技術は、果汁・野菜ジュース、ミネラルウォーター、医薬品分野の多くの製品の無菌生産・加工にも適用できます。

ヨーグルトとは何ですか?

ヨーグルトは、牛乳を原料として乳酸菌によって発酵させた、栄養価が高く、風味豊かな発酵乳製品の一種です。健康効果も期待できる食品でもあります。

ヨーグルトの分類

- 組織の状態や製品の製造方法に応じて、凝固ヨーグルトと撹拌ヨーグルトに分けられます。

- また、原材料に含まれる脂肪分の違いによってホールヨーグルトとスキムヨーグルトに分類することもできます。

- 菌の種類により、一般的なヨーグルト、ビフィズス菌ヨーグルト、アシドフィルス菌ヨーグルト、カゼイ菌ヨーグルトに分けられます。

- 製品によって、味はナチュラルピュアヨーグルト、フレーバーヨーグルト、加糖ヨーグルトなどに分けられます。

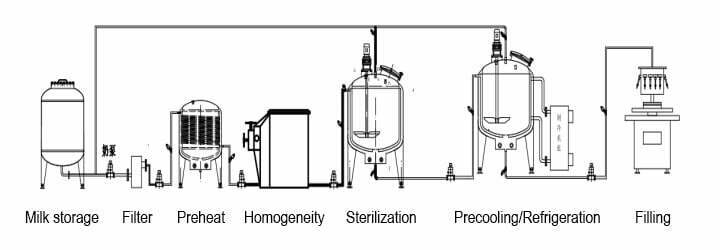

凝固ヨーグルトの製造工程

生乳受入れ精製→標準化→濃縮→予熱→均質化→殺菌→冷却→発酵液添加→充填→定温培養→冷却、後熟成→製品

ヨーグルト加工ラインの製造工程のポイント

生乳の受け入れ

- 生乳の総乾物含有量は 11.5% 以上である必要があります。また、無脂肪乾物は 8.5% 以上である必要があります。そうしないと、プロテインのゲル効果に影響を与えます。

- ないはずです 抗生物質 残留物。

- 酸性度 ≤ 18°T。

ヨーグルト製造の主な原料

- 砂糖と果物の材料

サワーミルクの製造では、スクロースまたはグルコースの 5-8% がよく添加されます。 - 脱脂粉乳

要件: 高品質、抗生物質、防腐剤不使用。

目的: 乾物含有量を増やすため。製品の組織状態を改善します。乳酸菌による酸の生成を促進します。一般添加量:1~1.5%

集中

目的:固形分を増加させ、発酵凝固を促進します。

方法:減圧濃縮

予熱と均質化

予熱の目的:均質化効果を高めるため。 55〜60度。均質化の目的: 混合物の安定性を維持するため。均質化条件: 15-20 MP。

滅菌と冷却

滅菌とは、生乳中のすべての病原菌とほとんどの雑菌を殺すことです。また、殺菌により牛乳中のタンパク質の水和を改善することができます。

滅菌後の冷却温度:43〜45度。

発酵剤と接種

接種量:1-3%。

接種量に影響を与える要因

- 発酵中のインキュベーション温度と時間。

- 発酵剤の酸生成能力。

- 製品の冷却速度。

- 牛乳の品質。

充填

容器:磁器瓶、ガラス瓶、ペットボトル、紙パックなど

充填方法:手動充填、半自動充填機、自動充填機など。ヨーグルト充填機は充填速度を向上させ、改善するのに役立ちます。

発酵:ヨーグルト発酵タンク

培養温度:使用する菌株と比率によって決定されます。

栽培時間:短時間栽培:41〜42度、3時間。長時間インキュベーション: 30 ~ 37 度、8 ~ 10 時間。

影響因子: 接種量、発酵槽の活性、インキュベーション温度。

冷却

条件: 3 ~ 5 度。 5℃はカビや酵母の増殖の下限です。

目的

- 乳酸菌の増殖を抑制し、酵素の活性を低下させ、過剰な酸の生成を防ぎます。

- 脂肪の浮遊速度とホエイの沈殿速度を遅くし、保存期間を延長します。

- 香気物質の生成促進

冷蔵および後熟成

条件: 2 ~ 7 度、12 ~ 24 時間。

Taizy Food Machineryでは、小規模ヨーグルト生産ラインとヨーグルト生産設備を一式取り扱っています。必要であれば、ぜひお気軽にご連絡ください。