The ultraviolet food sterilization machine, renowned for its high efficiency, eco-friendliness, and absence of chemical residues, has become the ideal choice for industries such as food processing, pharmaceuticals, and water treatment. This device utilizes high-frequency C-band (253.7nm) ultraviolet radiation to disrupt the DNA structure of microorganisms like bacteria and viruses, rendering them incapable of reproduction and survival, achieving a sterilization rate as high as 99.99%.

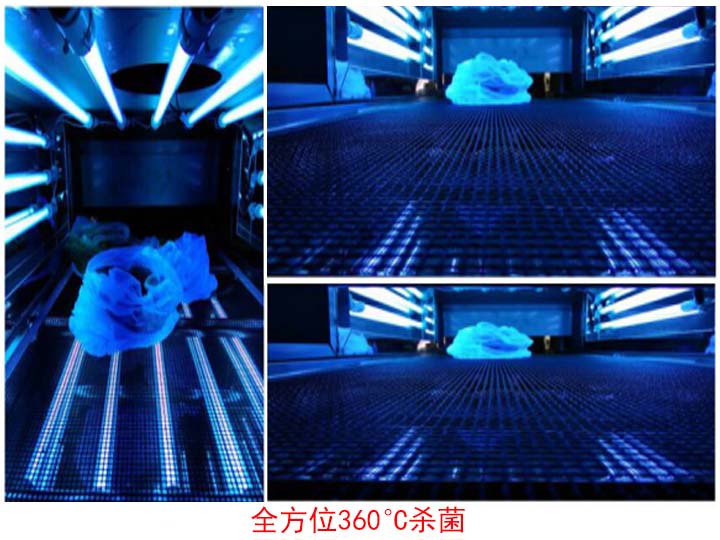

Constructed entirely from 304 or 316 stainless steel with mirror-polished interior surfaces, the unit maximizes UV reflectivity to achieve 360° sterilization without blind spots. Compared to traditional thermal sterilization or chemical disinfection methods, UV sterilization offers significant advantages including simplified operation, low energy consumption, zero pollution, and minimal maintenance.

Furthermore, this ultraviolet food sterilization machine finds extensive application across multiple sectors, including food processing, beverage filling, pharmaceutical manufacturing, medical devices, laboratory environments, and potable water treatment, delivering high-standard sterile assurance for modern industrial operations.

Application of ultraviolet food sterilization machine

The ultraviolet food sterilization machines are suitable for various industries and settings requiring high hygiene standards, including but not limited to:

- Food and beverage processing: rapid sterilization of food surfaces, packaging materials, production pipelines, and drinking water.

- Pharmaceutical and cosmetic industries: sterilization of pharmaceutical packaging, medical instruments, and laboratory environments.

- Public health sector: air and surface disinfection in hospitals, schools, stations, hotels, cold storage facilities, and similar venues.

- Electronics and laboratory environments: sterile maintenance for cleanrooms and experimental equipment.

Thanks to its physical disinfection properties and absence of chemical residues, UV sterilization equipment is progressively replacing traditional chemical disinfection methods in the global eco-friendly disinfection market.

Characteristics of the UV light for food sterilization

- High-efficiency sterilization performance: utilizing high-frequency C-band UV lamps, it rapidly eliminates bacteria, viruses, fungi, spores, and other microorganisms within a short timeframe, achieving a sterilization rate of up to 99.99%.

- Safe, eco-friendly, and pollution-free: employing purely physical sterilization without any chemical additives, it is non-toxic, free from side effects, and prevents secondary pollution.

- Durable and stable: lamp lifespan reaches 8,000-9,000 hours with consistent irradiation intensity. Equipped with audible and visual alarms for easy maintenance.

- High reflectivity design: interior walls feature high-gloss mirror-finished stainless steel to maximize UV utilization, boosting sterilization intensity by 18%-27%.

- Smart and energy-efficient: simple operation, easy installation, compact footprint, low energy consumption, and significantly reduced operating costs compared to traditional equipment.

- Multi-scene applicability: optional lamp tubes with varying wattages and quartz glass protective tubes accommodate diverse sterilization needs for water, air, and surface disinfection.

Performance parameter of the ultraviolet food sterilizer

Product name: Ultraviolet Food Sterilizer

Model: HT-UV-2000

This product conforms to GB 4789.2, GB 4789.3, GB 4789.4, GB 4789.5 and GB 4789.10.

Ultraviolet food sterilization machine main dimension

- Full length of equipment: 2000mm

- Working area: 1200mm

- Feeding area: 400 mm

- Discharge area: 400mm

- Entrance and exit height: 0-200 mm (adjustable)

- Conveyor belt distance to ground: 750+20mm

Construction of ultraviolet food sterilization machine main body

- Tunnel outer body in the working area: 1.2mm high-quality stainless steel

- Tunnel cavity in the working area: 1.2mm mirror stainless steel plate

- Body support frame: fangtong steel

- Air transportation system: forced combined air extraction fan (extraction of harmful gases)

- Conveyor belt: teflon mesh belt

- Lamp height: 200mm

- Balance device: horizontal foot cup

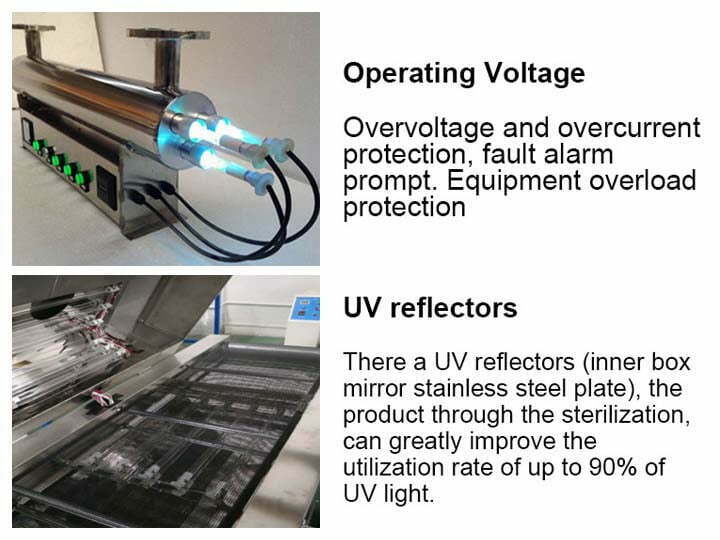

Equipment electrical part

- Master Switch: 15A

- Total power: 2.5KW

- Speed regulating the range of mesh belt: 0-5m/min

- Transport motor: 800W (frequency converter speed control)

- Speed Governor: 500W (Electronic Stepless Frequency Converter Speed Regulation, Digital Display Speed Operation)

- Exhaust fan: CY-125

- Amperometry: 50A set

- Voltmeter: 220V set

- Operating Voltage: 220V (+5) Three-wire 50Hz

Ultraviolet food sterilization machine sterilizing device

- Effective radiation of ultraviolet light source. The lamp length is 900mm, and the effective light distance is 950mm.

- 16 * 20W ultraviolet lamp tubes are equipped in all directions from top to bottom, and 360 degrees are sterilized in all directions. In addition, each tube is equipped with a separate control switch that can be operated independently.

Protection device

- Overvoltage and overcurrent protection. The over-current protection device is that when the power supply voltage is higher than a certain value, the protector cuts off the line; when the power supply voltage restores to the normal range, the protector automatically turns on. The overvoltage protection device is that when the current exceeds the set current, the device automatically powers off to protect the equipment.

- Fault alarm alert. When the equipment fails, the alarm device will give an alarm for the first time to minimize the damage value.

- Equipment overload protection. When the carrying weight of the conveyor belt exceeds the normal range, the equipment will automatically remind you to avoid damaging the machine.

How does a UV sterilizer work?

Ultraviolet light is a high-energy electromagnetic wave with a wavelength between 200-280nm, possessing extremely potent sterilizing properties. When microorganisms are exposed to ultraviolet radiation, their DNA and RNA absorb energy, causing breaks and mutations that prevent replication and reproduction.

Ultraviolet sterilization units emit ultraviolet photons at a wavelength of 253.7nm through high-frequency lamps, destroying the genetic material of bacteria and viruses within mere tens of seconds to achieve complete inactivation.

The unit features a mirror-finished stainless steel reflective chamber design. Ultraviolet light undergoes multiple reflections within the chamber, achieving 360° comprehensive irradiation to ensure uniform sterilization. High-intensity sterilization is typically completed within 3-5 minutes, providing safety assurance for food and pharmaceutical production.

Usage notices

- Ultraviolet disinfector is strictly prohibited from starting frequently, especially in a short time.

- According to the water quality, the ultraviolet lamp tube and quartz glass sleeve need to be cleaned regularly. Moreover, the test tube should be wiped with an alcoholic cotton ball, or gauze, to avoid affecting the ultraviolet transmittance.

- When replacing the lamp tube, please check whether there is water leakage, and then plug in the power supply. Be careful not to touch the quartz glass of the new lamp tube with your fingers, otherwise, the sterilization effect will be affected by the stain.

- Preventing ultraviolet radiation. Ultraviolet radiation also has an effect on the human body to some extent. When starting the disinfection lamp, we should avoid direct radiation on the human body. If necessary, we should use protective glasses. We should not directly face the light source with the eyes, to avoid burning the eye film.

Pay attention

- Shipment. The ultraviolet food sterilization machine is shipped in wooden cases to reduce the risk of wastage during transportation. Generally, small machines can be transported nearby for only 3-8 days. If you customize a special machine model, we need extra time to make the machine or its parts, which takes a little longer, but most of it is controlled within 30-50 days.

- About after-sales. The warranty period is two years. During this period, if you have any quality problems, please contact our online customer service to reflect the situation, we will provide you with a warranty or replacement service.

- Generally speaking, the conveyor belt of this machine is the Teflon mesh conveyor belt. By the way, but if you have special needs, such as handling some powdered goods, you can customize the PVC transparent conveyor belt.

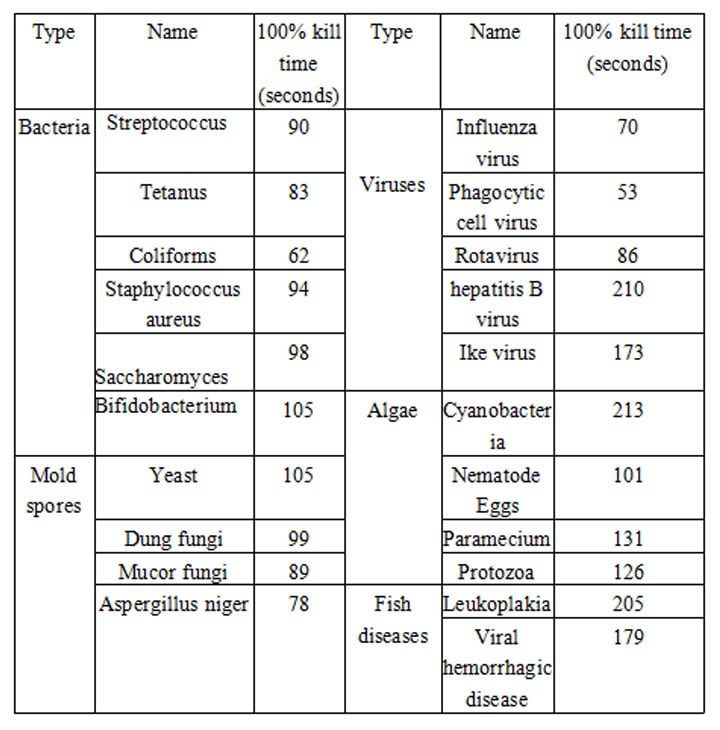

How long does it take for ultraviolet light to kill bacteria?

Ultraviolet rays can cause irreversible damage to bacterial DNA. For different bacteria, the sterilization time required is not the same. The following schedule will tell you the exact time required for sterilization:

Successful cases

Kruz, Philippines, owns a banana slice factory. He found this ultraviolet food sterilizer when he visited our food website. He was very interested in this non-toxic and harmless sterilization mode without adding any chemicals. Soon, he contacted our sales manager for details. After negotiation, he decided to visit our company in person. During the inspection, he expressed his satisfaction with the use of the ultraviolet food sterilization machine and placed an order immediately.

Here, we express our great welcome to any international friends to visit our company on the spot. Zhengzhou Taizy Machinery Equipment Co., Ltd. is a complete system of equipment production, research, development, and sales in one. We have experience and confidence in facing any professional and technical problems and look forward to your cooperation.