Bun making machine is an intelligent automatic machine, that can be used to make meat buns, vegetable buns, round steamed bread, Fried buns, and so on. The machine consists of three systems, a filling system, a momo making system, and a bun forming system.

The structure of the bun making machine

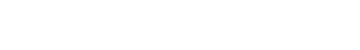

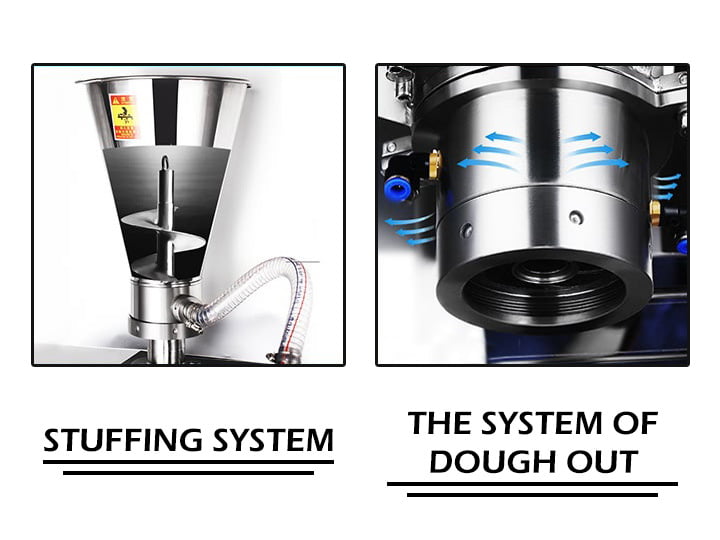

The bun making machine is mainly composed of a stuffing bucket, a filling conveying tube, a forming cutter, a conveyor belt, a stainless steel body, universal wheels, a dough discharge, a control panel, the dough press system, and a dough bucket (please refer to the following figure for details). In addition, there are two models of this machine, namely the single hopper bun machine and the double hopper bun machine. The double hopper machine is more suitable for the production factory where the filling is frequently changed.

How does the bun making machine work?

First of all, the prepared dough is placed in a dough hopper. And then the double-helical auger in the hopper repeatedly squeezes the dough, pushes it to the dough discharge, and forms a hollow dough tube at the outlet. Next, the filling system injects the filling into the hollow dough tube. Finally, the forming cutter will shape the baozi according to the set weight. What’s more, the thickness of the bun, the weight of the bun, and the weight of the filling are all adjustable. By the way, the prepared buns also need to be steamed before they can be eaten.

The recommended machines for making momo are dough mixers, chopping machines, meat grinders, and multi-function vegetable dicing machines.

Video: How to use the momo maker?

Automatic momo maker features:

- The momo making machine is made of food-grade stainless steel, and the shell is easy to disassemble and easy to clean.

- High output per unit of time. The production of steamed buns with different weights is different, and the maximum output can reach 3000 pieces per hour.

- The baozi maker machine uses a dual-frequency control system, and the weight of the dough and fillings can be adjusted.

- The dough forming part is made of imported high polymer material, which is molded once and is not easy to be deformed.

- The weight of the steamed momos can be adjusted between 40-200g.

- The original vortex filling system has been improved, and the stuffing filling is more stable.

- Cost savings, the output of one bun making machine is equivalent to more than a dozen skilled workers working at the same time, which can save manpower expenses.

Technical parameter:

| Type | Voltage | Power | Capacity | Size (mm) | Machine weight (kg) | Bun weight (g) |

| Tz-1 | 220v/110v | 2.2kw | Max 3600 pcs/h | 1400×700×1500 | 240 | 20-200 |

| Tz-2 | 220v/110v | 2.2kw | Max 3600 pcs/h | 1400×700×1700 | 280 | 20-200 |

The table shows two momo making machines. The maximum capacity is 3600 per hour.

Frequent questions and troubleshooting of bun making machine:

- The bottom of the bun is too thin, and it is easy to leak out the filling.

A: It may be because the filling is too hard, the dough is too soft, and the filling breaks through the dough during the molding process.

- The steamed momos are glued to each other without separation.

A: The gap between forming tools is too large. Then you need to adjust the spring around the forming plate and tighten the forming plate.

- There is no stuffing inside the bun.

A: The main reason is that the fillings do not meet the requirements, the fillings are too hard or the water content is too little. So, it’s better to modulate again according to a certain proportion.

- The electronic control is out of order.

A: The specific situation needs to be resolved by calling the company or the after-sales service department. Keeping the electrical components of the equipment dry and clean is beneficial to prolong the service life of the original electrical components.