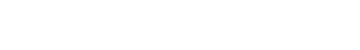

The commercial fruit juice machine is a movable machine. The materials contacted with fruits and vegetables are high-quality, acid-resistant and alkali-resistant stainless steel. It is suitable for extracting juice from grapes, seabuckthorn fruits, pomegranates, ginger, spinach and other fruits and vegetables containing more fibers, and for dewatering fibrous materials such as domestic garbage, vegetable market garbage, kitchen garbage, and medicine residue.

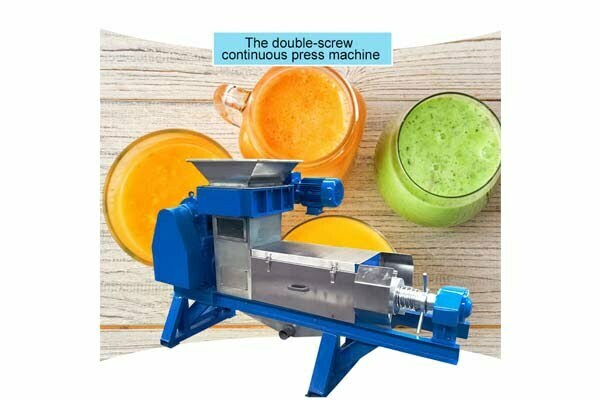

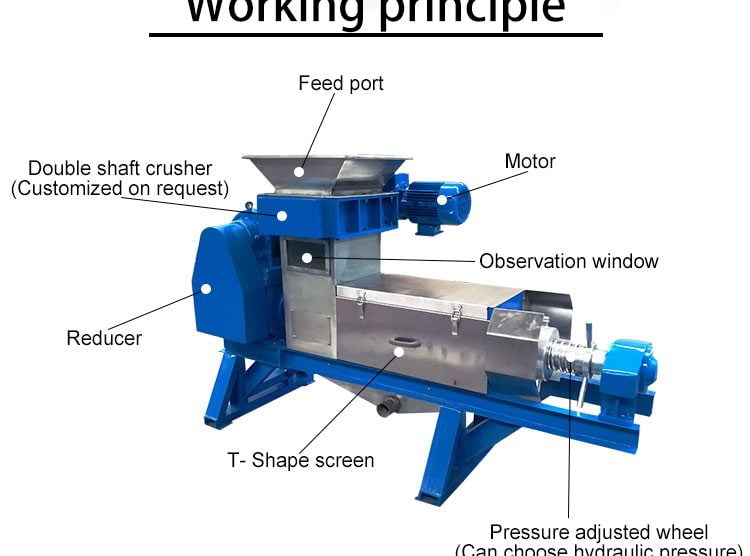

Components of Commercial Fruit Juice Machine

The commercial fruit juice machine is composed of a frame, transmission system, feeding part, juice extracting part, hydraulic system, protective cover, and electrical control part.

The press screw rotates with the spindle, and the material conveying screw rotates in reverse with the pressing screw. This set of equipment is developed and reformed on the basis of the press, which responds to the needs of customers. A set of crushing extrusion rolls is added at the entrance of the feeding box to crush the material before pressing, which can achieve a better-juicing effect. Therefore, it is especially suitable for juice extraction of jujube, apricot, pear, onion, garlic, ginger, and other juices.

Working Principle

This commercial juicer extractor machine is a crushing-type screw press. The working process is: after the material enters the crushing box, the crushing rod breaks the material by high-speed rotation, and the material is put into the press system. Then the conveying screw pushes the material entering the feeding box. By reducing the pitch and increasing the diameter of the screw, the liquid (juice) contained in the material is extruded. The extruded liquid flows out of the sieve hole and concentrates in the juicing hopper.

After pressing, the dregs are discharged from the commercial fruit juice machine between the end of the sieve barrel and the cone body. The rear part of the cone body is equipped with springs. By adjusting the pre-tightening force and position of the springs, the resistance of the dregs discharging and the size of the dregs outlet can be changed. This method can be used to adjust the dryness and wetness of pressing.

Video: Introduction of the Commercial Fruit Juice Machine

Advantages of the Industrial Juicer Machine

- Excellent material. This commercial fruit juice machine is made of high-quality acid and alkali-resistant stainless steel, which not only meets the food hygiene and safety standards but also minimizes the wear and tear of the machine.

- Strong power; High quality and a powerful motor to ensure strong power output.

- Extrude dehydrated materials forcefully, and a double helix system ensures that the material is pressed more fully.

- Corrosion-resistant reinforced screen, hard-pressed materials can be squeezed.

- Crushing press. Crushing material before feeding, can crush large materials into small materials to reduce machine wear and improve material juicing rate.

Details Of Industrial Fruit Juicer Machine

Application Range Of The Vegetable And Fruit Juicer

Scene Shot Of Fruit Juice Machine

Use and Maintenance

- Before feeding, the cone body and the outlet should be closed, and the pre-tightening force of the pressure spring should be properly adjusted by the nut. After slag resistance is formed, the squeezing effect should be checked, and then the degree and position of the spring should be properly adjusted to achieve a satisfactory squeezing effect.

- When feeding materials, stones or other things should be prevented from entering the commercial fruit juice machine. Branches larger than 8 mm in diameter should be removed to avoid damaging the sieve barrel.

- At the end of pressing, the spring should be relaxed beforehand, and the fruit residue behind should not be compacted to facilitate removal. When not in use for a long time, the commercial fruit juice machine should be cleaned and the rusty parts should be protected by grease.

- The transmission system, transmission parts, and bearings should be regularly filled with lubricating oil or grease.

Parameters of Commercial Vegetable and Fruit Juice Machine

| Model | TZ-1.5 | TZ-3 | TZ-5 | TZ-10 | TZ-15 | |

| Capacity | 0.2-1.5t/h | 0.5-2t/h | 2-6t/h | 3-10t/h | 5-16t/h | |

| Conveying screw | diameter | 260mm | 350mm | 420mm | 500mm | 600mm |

| pitch | 150mm | 200mm | 210mm | 280mm | 280mm | |

| Press screw | diameter | 260mm | 350mm | 420mm | 500mm | 600mm |

| speed | 5-15r/min | the same | 5-15r/min | the same | 5-15r/min | |

| Power | 505kw | 7.5kw | 11kw | 18.5kw | 22kw | |

| Screen diameter | 270mm | 360mm | 430mm | 510mm | 610mm | |

| Screen aperture | 1.5mm | 1.5mm | 2*40mm | 2*40mm | 2*40mm | |

| Size(m) | 2.2*0.6*0.9 | 3.5*0.7*1 | 3.5*1*1.5 | 3.8*1.1*1.65 | 4.5*1.1*1.65 | |

| Weight(kg) | 650kg | 1200kg | 2550kg | 2950kg | 4200kg | |

As a professional supplier of fruit juice processing equipment, we have a variety of commercial juicer machine for you to choose from. Small Juicers can handle 0.2 tons per hour, while large Juicers can handle 16 tons per hour. This means that our commercial fruit juice machine can meet the requirements of a variety of customers.

We have commercial fruit juice machine of different specifications and output for your choice. In addition, we also have vegetable washing machine and vegetable/Fruit cutting machine for sale. If you have any other questions, please contact our customer service.