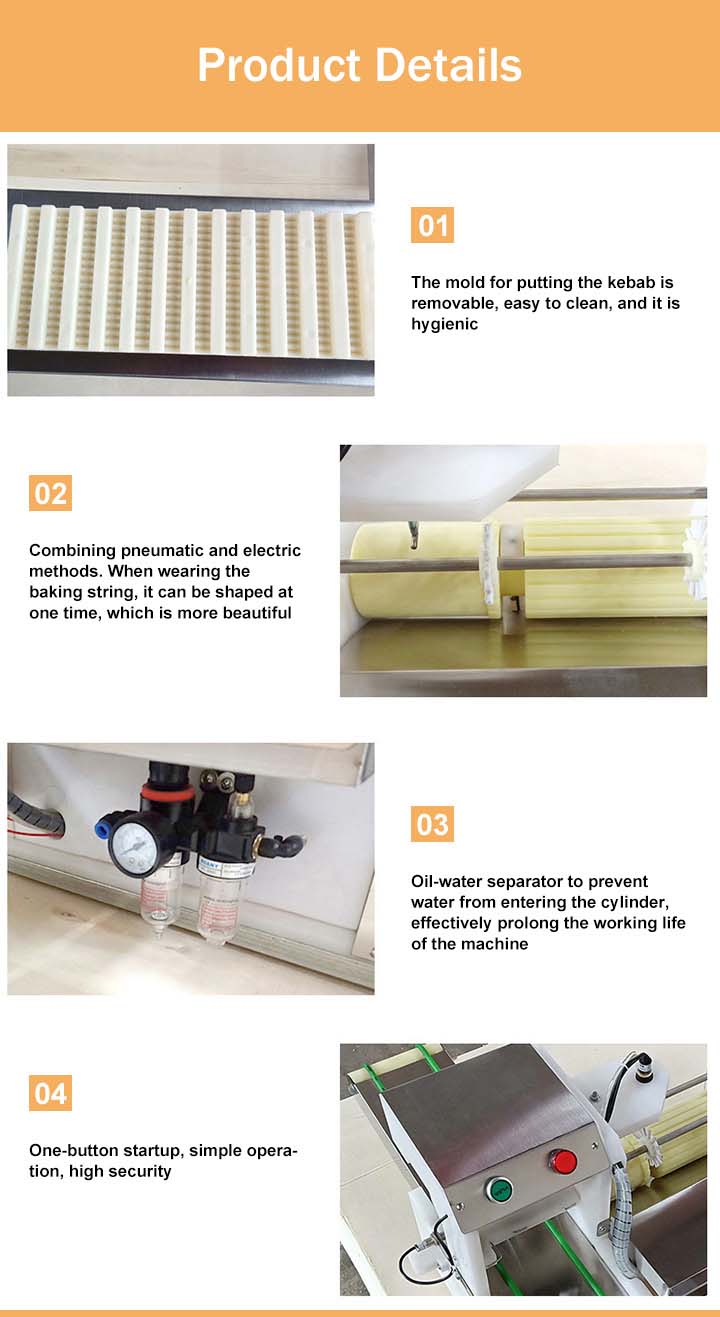

The automatic meat skewer machine is a commercial device that integrates high efficiency, intelligence, and safety, designed to replace traditional manual skewering methods. Combining pneumatic and electric drive systems, this equipment not only boosts productivity but also ensures meat skewers are uniform, neat, and secure.

Each skewer takes only 1.5–2 seconds to prepare, equivalent to the output of over a dozen workers, saving businesses over 10,000 yuan annually in labor costs. It is an ideal choice for barbecue restaurants, food factories, snack streets, and restaurant chains.

Application scope of kebab skewer machine

This multi-functional skewer machine is suitable for skewering various ingredients, including:

- Meat: beef skewers, lamb skewers, chicken skewers, pork skewers, meatball skewers, etc.

- Seafood: shrimp skewers, fish fillet skewers, etc.

- Vegetarian: vegetable skewers, tofu skewers, mushroom skewers, etc.

- Specialty items: candied hawthorn on sticks, rock sugar fruit skewers.

The skewered items are uniformly sized, clean, neat, and securely fastened without loosening. They remain intact during grilling or cooking. Skewer lengths typically range from 25–40cm and can be customized to meet customer requirements.

Automatic skewer machine advantages

- High efficiency & energy savings: reaches up to 2100 skewers per hour, over ten times faster than manual labor.

- Smart control: utilizes a PLC digital control system with photoelectric sensing technology for smooth operation and precise positioning.

- Safety and reliability: eliminates finger cuts common during manual skewer insertion while significantly reducing labor intensity.

- Multi-purpose design: capable of producing not only standard meat skewers but also candy skewers and fruit skewers, offering broad applicability.

- Durable construction: constructed with food-grade stainless steel housing, reinforced cylinders, and sealed pistons for exceptional wear resistance, pressure tolerance, and extended service life.

- Flexible customization: supports personalized adjustments for speed, skewer length, and production configurations to meet diverse commercial requirements.

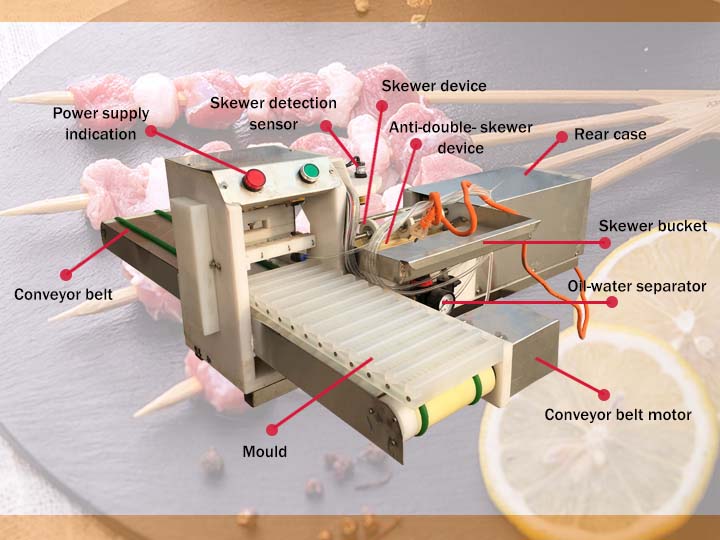

Automatic meat skewer machine working principle

The skewer machine achieves automated operation through a pneumatic system and intelligent control system:

- Automatic feeding: place meat chunks or ingredients into the storage bin.

- Precise detection: photoelectric sensors locate the ingredients.

- Rapid skewering: pneumatic actuators drive skewers through ingredients at high speed with uniformity.

- Single-skewer release: only one skewer is dispensed per cycle, ensuring accuracy and preventing duplicate errors.

- Continuous operation: PLC-controlled continuous and stable operation guarantees consistent output and quality.

Efficient skewer machine technical parameters

| Cover material | Stainless steel + food grade PE plastics | Work efficiency | 1.5-2.0 seconds / wearing |

| Use Motivation | Pneumatic power | Meat skewer speed | 1800-2000 wearing skewers/hour |

| Control Section | Microcomputer control | Size | 1000*1000*350mm |

| Weight | 30kg | Length of type 30 skewer | 250-300mm |

| Motor Power | 60w | Type 35 | 300-350mm |

| Voltage | 220v | Type 40 | 350-400mm |

| Leakage Protection | Have | Skewer diameter | 3.0-3.5mm |

From this table, we can see that our automatic meat skewer machine can string 1800-2000 kebabs per hour. This is much faster than artificial speed. By the way, you can choose different skewer lengths according to your needs. In this table, we have three skewer lengths: 250-300mm, 300-350mm, and 350-400mm.

How to make homemade barbecue sauce?

- Put peeled Onion, and garlic into the mixer and beat into a paste.

- Heat the butter in the pan, pour in the onion paste and garlic paste, and fry them to a yellowish color.

- Add a small glass of juice or water.

- Add chili sauce, tomato sauce, honey, yellow mustard, etc. in order.

- After boiling, add salt, black pepper, chili powder, and thyme powder. Stir well and add the apple cider vinegar.

- Add a cup of water and cook for 20-30 minutes to make a delicious barbecue sauce.

By the way, If you don’t like the sweet-spicy taste, you can change the juice into clear water. The proportion of salt and pepper depends on their taste.

How to maintain an automatic skewer machine?

- Maintaining an automatic skewer machine is crucial to ensure optimal performance and longevity.

- Regular inspection and cleaning of components such as the skewer tracks, motors, and blades are essential.

- Lubrication of moving parts prevents friction and enhances efficiency.

- Conducting routine tests for alignment and calibration guarantees precise skewering.

- Additionally, documenting maintenance schedules and adhering to manufacturer-recommended procedures are fundamental.

Related machines

Chain type barbecue grill machine

Feel free to contact us anytime for more information on meat processing machinery and customized solution quotes!