A meat bone separator is suitable for separating the meat and bone of poultry. This meat and bone separating machine uses the working principle of screw extrusion to squeeze meat into mince and leak it out of the screen. Then turn the bone into bone dregs and discharge them from the front of the machine. The working efficiency of this machine is very high, the output is about 0.3 – 4 tons per hour.

Application market of the meat bone separator:

- This meat separator machine is suitable for separating the flesh and bones of small poultry, such as chicken, duck, goose, rabbit, etc. The separated meat is directly made into minced meat, and the bones are broken into bones.

- Minced meat can be used to make sausages, meatballs, hamburger patties, etc. Therefore, it can not only ensure the meat content but also reduce the production cost.

- The broken bone dregs can be used to boil bone soup, make animal nutrition feed, extract chondroitin, make bone meal, etc.

Introduction of bone and meat separating equipment:

Structure and composition:

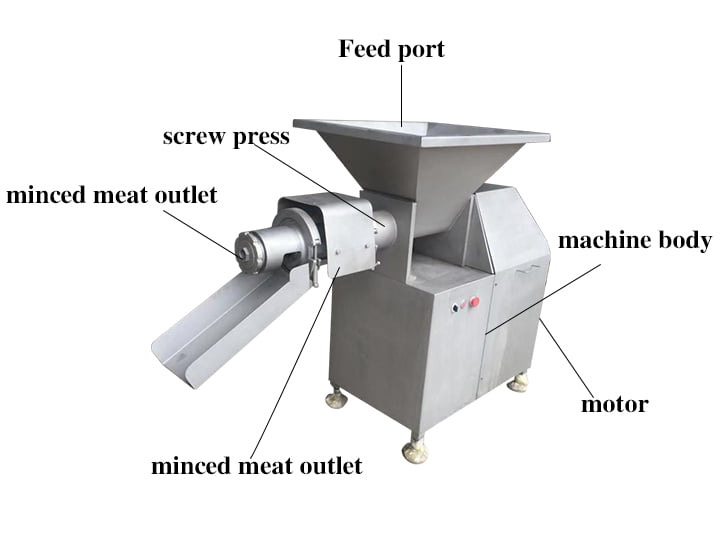

This bone separator machine is mainly composed of a feed inlet, screw press, fuselage, minced meat outlet, bone dregs outlet, motor, and other parts.

How does a poultry meat-bone separator work?

The inside of the high quality meat bone separators machine is a single screw structure. After the raw materials are put into the feed hopper, the screw continuously pushes the materials forward. After the material enters the squeezing chamber, it is broken under the strong squeezing pressure between the squeezing screw and the squeezing chamber. The front part of the pressing chamber is a reinforced mesh screen. The broken bone follows the rotation of the snail, and is continuously pushed forward, and finally discharged from the discharge port.

Technical Parameters of bone meat separator:

Take the model with the smallest output as an example.

| Type | 300 |

| Power (KW) | 5.5 |

| Voltage (V) | 380/50Hz |

| Meat yield | 70-80%(Depending on meat content) |

| Output (kg/H) | 300kg |

| Weight (Kg) | ≈500 |

| Size(mm) | ≈1450x650x1250 |

The output of this meat bone separator is 300kg per hour. The meat yield is 70-80%, it depends on the meat content. The size of the machine is 1450*650*1250mm. If you need this high-quality bone separator machine, please feel free to contact us.

Advantages of the mechanically deboned meat machine:

- Taizy poultry processing machine can effectively separate meat from the bone, and the meat production rate can reach about 70-80%, saving production costs.

- The separation effect is good. The separated bones and meat are discharged from different places. So, the meat is fine and does not contain any bone residue.

- The temperature rise of the meat bone separator machine is small in the process of operation. So. it can ensure that the nutritional components of meat will not be lost in the process of processing.

- The separator is made of 304 stainless steel, which is conducive to disassembly and cleaning. The core parts have strict processing technology and special heat treatment technology, which can effectively extend the service life of the machine.

- High efficiency and low noise.