The meat bone separator is an efficient equipment designed for poultry processing. Adopting the advanced spiral extrusion principle, it can quickly and efficiently separate the bones and meat of chicken, duck, goose, rabbit, and other animals.

The whole machine is made of imported high quality 304 stainless steel, with smooth operation, low noise, easy to clean and maintain.

It is especially suitable for meat processing plants, canning plants, frozen food factories and pet food manufacturers and other customers who have the demand for high yield and high quality of minced meat.

This equipment can greatly improve the output rate and reduce the production cost. It has a high working efficiency with an output of about 0.3 to 4 tons per hour, which is one of the important equipments in modern meat production line.

Application market of meat bone separator

- Poultry processing plant: used for bone and meat separation of whole chicken, chicken skeleton, chicken leg cartilage, chicken neck, duck skeleton, goose skeleton and so on.

- Livestock and poultry by-products reuse: the separated minced meat can be widely used to make sausage, meatballs, luncheon meat, fishballs, hot pot material, etc.

- Pet food and animal feed processing: bone residue can be used to make bone meal, animal nutrition feed or extract chondroitin.

- Food and pharmaceutical industry: it can be used for the separation of fruit pulp and kernel, such as jujube, goji berry, plum and so on. The separated puree is suitable for the production of food, flavorings and pharmaceutical raw materials.

- Convenient food and seasoning enterprises: minced meat can be used as the core raw material of soup, seasoning packet and hot pot base.

Advantages of mechanically deboned meat machine

- High meat yield: the meat recovery rate is as high as 70%-80%, effectively improving the yield.

- Thorough separation: meat and bone residue are discharged from different outlets, no bone residue left in the minced meat, stable quality.

- Low temperature treatment: low temperature rise during the separation process, effectively retaining the original nutrients of meat.

- All stainless steel body: made of food grade 304 stainless steel, sturdy structure, corrosion resistance, in line with food hygiene standards.

- Long life of core components: strict heat treatment and precision technology to ensure long and stable operation of the machine.

- Smooth running and low noise: suitable for continuous operation without affecting the working environment.

- Easy cleaning and maintenance: modular design, easy to disassemble, easy for daily cleaning and maintenance.

Bone and meat separating equipment working principle

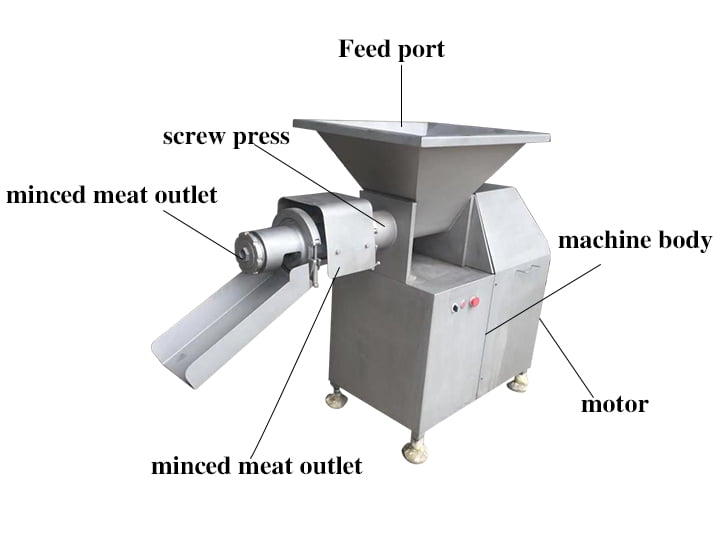

Structure and composition

This meat bone separator machine is mainly composed of a feed inlet, screw press, fuselage, minced meat outlet, bone dregs outlet, motor, and other parts.

How does a poultry meat-bone separator work?

- The meat bone separator is internally designed with single screw propulsion. The raw materials are continuously pushed from the feed hopper to the extrusion area to ensure that the materials enter the working chamber evenly.

- After entering the extrusion chamber, the raw material is crushed by the strong pressure generated between the screw and the wall of the extrusion chamber, realizing the preliminary separation of bone and meat.

- There is a reinforced screen device at the front end of the extrusion chamber. The delicate minced meat is extruded out of the screen under pressure, while the larger bone residue is pushed forward.

- The crushed bone residue is pushed forward by the rotating screw, and finally discharged through the independent discharge port to ensure the complete separation of meat and bone.

Technical parameters of bone meat separator

Taizy poultry processing machine can effectively separate meat from the bone, and the meat production rate can reach about 70-80%, saving production costs. Take the model with the smallest output as an example.

| Type | 300 |

| Power (KW) | 5.5 |

| Voltage (V) | 380/50Hz |

| Meat yield | 70-80%(Depending on meat content) |

| Output (kg/H) | 300kg |

| Weight (Kg) | ≈500 |

| Size(mm) | ≈1450x650x1250 |

The output of this meat bone separator is 300kg per hour. The meat yield is 70-80%, it depends on the meat content. The size of the machine is 1450*650*1250mm.

If you need to meet different raw material processing needs, we also provide a variety of specifications and models of poultry meat bone separator equipment. Welcome to contact us for personalized solutions and field test experience!