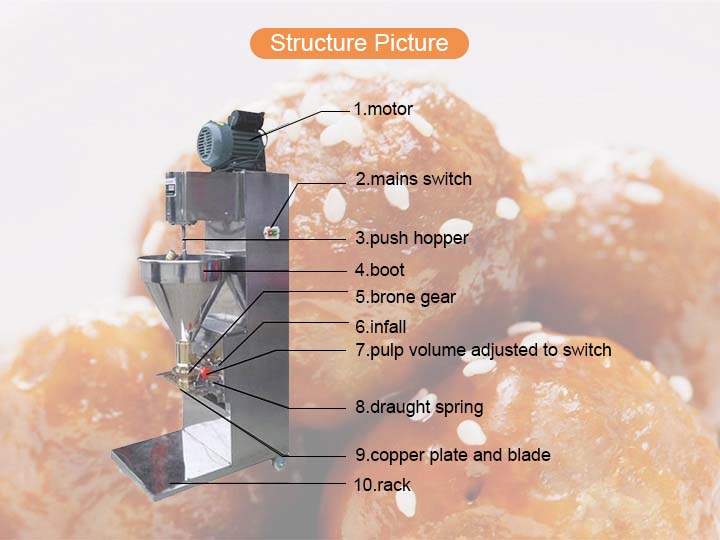

The meatball production line is composed of a meatball forming machine, a meatball blanching machine, a frozen meat planer, and a frozen meat grinder, and some other machines. Our meatball production line is a semi-automatic production line. It’s suitable for making meatballs of various tastes. The meatball forming machine imitates the principle of artificially making meatballs. So, it can make chicken, beef, and mutton meat into delicate meatballs.

How are meatballs processed?

Here is the complete meatball production process.

- The raw material is -4 ℃ ~ -18 ℃ frozen meat, which can be chicken, pork, lamb, beef, fish.

- First, cut frozen meat into slices for processing and use.

- Secondly, put the sliced frozen meat into the meat grinder to make smaller meat pieces.

- Thirdly, put the ground meat into the chopper, cut the meat continuously, and cut the meat more evenly. In this step, you can add seasoning for seasoning.

- Fourthly, use the beater to break the minced meat continuously. You can also choose to add seasoning in this step to obtain the minced meat with fine quality.

- Nrxt, put the minced meat into the meatball forming machine. You can cook and shape meatballs directly in a blanching machine.

- Finally, cool the meatballs in a cooler. After cooling,we can sell meatballs directly or freeze them in the fridge.

What Are the Meatball Forming Machines in the Meatball Production Line?

Raw frozen meat — frozen meat planer — frozen meat grinder — chopping machine — meat beater — meatball forming machine — blanching, cooking, cooling production line

Frozen meat planer

Frozen meat planer had another name-hydraulic frozen meat planer. This machine is mainly composed of the feed chamber, rotary cutter, body, hydraulic push plate, motor, and other parts. It uses the principle of hydraulic feeding to push the meat into the rotating blade, which has the characteristics of consistent slice thickness and high efficiency. It can cut bone-free frozen meat at – 4 ℃ ~ – 18 ℃ in a short time, so as to facilitate subsequent processing, prevent the meat grinder from overload and affect the service life of the machine.

Frozen meat grinder

This frozen meat grinder does not need to thaw meat, which greatly saves processing time. Changing the mold hole of the machine can get different sizes of meat particles. In the process of ground meat, the temperature of the machine is not very high, and it will not destroy the nutrients, protein, muscle tissue, etc. in the meat. The screw pushes the raw meat to the cutter so that the cutter and the outlet of the machine produce a squeezing force. Under the dual action of the squeezing force and the twisting force, the meat becomes uniformly-sized meat particles and is discharged from the outlet.

Chopping machine

You can use the chopper to cut vegetables and meat. Therefore, it is suitable for the processing and production of the baozi shop, dumpling shop and meatball production line. Because this machine is made of high-quality 304 stainless steel. It can cut vegetables and meat more evenly in the process of chopping. There is a protective device above the machine to ensure the personal safety of operators. In addition, after special heat treatment, the cutter inside the machine has high rotation speed. It can reduce the grinding process of materials and prevent the taste from being affected by too high temperature.

Meat beater

The meat beater can make the meat particles into a more delicate meat paste. And the machine consists of a bucket, a rotating agitator, a motor, etc. There is a frequency converter in the machine, which can perform step-less speed regulation according to customer requirements. Fast stirring can make the fleshy fiber thin, and the meat filling can be more uniform and fluffy. You can add seasoning in this process to make the minced meat fully absorbed and saturated, and the taste is more delicate.

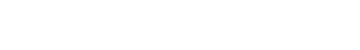

Meatball forming machine

This meatball forming machine simulates the process of making meatballs by hand and can be used to make meatballs of various flavors. A pound of raw meat can be made into 30-35 meatballs after adding appropriate seasonings and auxiliary materials. The size of the meatballs can be customized according to customer needs. The motor uses a full copper wire motor to ensure that the machine can run smoothly for a long time. In addition, the output of this machine is very large, and the number of meatballs produced per minute can reach 100-300.

How do you make meatballs easy to transport?

The prepared meatballs need to be shaped, cooked and cooled to facilitate the storage and transportation of the meatballs. So, you need to know this meatball blanching, cooking, cooling production line.

The first step is the blanching step. The purpose of blanching is to shape the meatballs. The blanching temperature is 60-70 degrees. In this step, you should use blanching machine.

Next is the cooking step, this process is only the preliminary processing of meatballs, which can effectively kill most of the bacteria in the meatballs. Because the cooking temperature is 75-95 degrees Celsius, the cooked meatballs cannot be eaten directly.

Finally, we need to cool the meatballs. The cooked meatballs need to be cooled before they can enter the freezer, so as not to affect the taste of the meatballs. The cooling step may be performed by directly cooling with normal temperature water. In addition, the blanching machine, cooking machine, and cooler have mesh belt conveyors inside, which can save labor.

Advantages of meatball production line

- All meatball making machines of this production line are made of high-quality 304 stainless steel, and the motors are international brands. Therefore, it ensures the quality of the machine.

- High production efficiency, this production line has multiple outputs, and the output range is 50-500 kg per hour.

- Support customization, the size of the machine, and the size of the final product can be customized.

- Can plan the factory for you, design the factory map, calculate the factory area, and so on.

Meatball production line for sale

The above is a complete meatball production process. The meatball production line is one of the main products of our company, so it has good quality. And if you have any questions about these machines, please feel free to contact us. And we will answer your questions as soon as possible.