The sausage processing line is a semi-automatic production line consisting of multiple machines. The main machines include a meat grinder, chopping machine, mixing machine, sausage filling machine, sausage knotting machine, smoking oven, and vacuum packaging machine. The raw materials can be chicken, pork, beef, etc.

Source of sausage

There are 250 different flavors of sausages, many of which can be traced back to a long history. Sausage, as a way to preserve and transport meat, was later loved by people because of its unique taste.

Introduction of sausage processing line

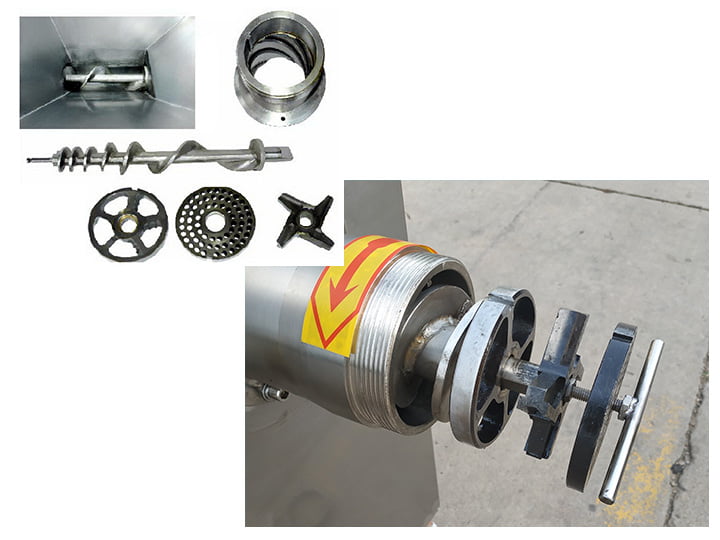

The main process of making sausages

Selection of raw materials – using a meat grinder to process raw materials into minced meat – chopping, stirring – seasoning and mixing – made sausages, filling – sausage knotted – smoking – packaging

Step 1: The selection of raw materials

The quality of raw materials directly affects the taste of sausages, so the choice of raw materials is very important. Meat should be of high quality and fresh, and it should not be infected by bacteria or microorganisms. Sausages made of unqualified meat will not only have a serious impact on the taste of sausages but also harm people’s health.

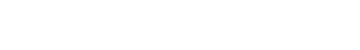

Step 2: Processing raw materials into minced meat

The meat grinder is the first machine in the sausage processing line. The frozen meat grinder can handle both fresh meat and frozen meat below -18 degrees Celsius. It can cut the meat into smaller pieces of meat. During the process of cutting the meat, it does not damage the muscle fiber and does not affect the taste of the meat. Before performing this step, the larger bones in the meat need to be removed to avoid damage to this sausage maker machine.

Parameters of meat grinder

| Type | Capacity (t/h) | Power (kW) | Cutter diameter (mm) | Cutter hole size (mm) | Size of the machine (mm) | Weight (kg) |

| JR-D100 | 0.3—0.5 | 4 | 100 | 3-25 | 950×550×1050 | 240 |

| JR-D120 | 0.3-0.6 | 7.5 | 120 | 3-25 | 950×550×1050 | 300 |

| JR-D130 | 0.6–1.2 | 7.5 | 130 | 3-25 | 1050×750×1300 | 600 |

| JR-D160 | 1-2 | 15 | 160 | 3-25 | 1600×1080×1460 | 1600 |

| JR-D200 | 1.5-3 | 27 | 200 | 3-25 | 2000×1480×1600 | 1800 |

| JR-D250 | 2–4.5 | 37 | 250 | 3-25 | 1800×1500×1600 | 1200 |

| JR-D300 | 5.5-6 | 55 | 300 | 3-25 | 1900×1500×1800 | 1800 |

A variety of meat grinders with different capacities for you to choose from.

Step 3: Chopping (chopping machine)

The chopping machine can cut the meat into a finer state and improve the hydrophilicity and elasticity of the meat. It is the necessary machine in the sausage processing line. The meat can be made into mince in a short time. The longer the time is, the finer the mince will be. Sausages with different tastes have different requirements for meat. You can adjust the time of chopping and mixing according to your needs. In the process of chopping and mixing, seasoning can be added for seasoning. This machine can keep the color, fragrance, taste and various nutrients of the original meat to the maximum extent.

The parameters of the chopping machine

| Type | Volume (L) | Capacity (kg/per time ) | Cutting speed(rmp) | pot(rmp) | Discharger speed(rmp) | Power kw | Size mm | Weight kg |

| ZB20 | 20 | 10 | 1500/3000 | 8/12 | No | 5 | 780×600×850 | 300 |

| ZB40 | 40 | 20 | 1500/3000 | 8/12 | No | 5.1 | 1100×860×950 | 500 |

| ZB80 | 80 | 65 | 1500/3000 | 8/12 | 83 | 12.65 | 2160×1370×1350 | 1200 |

| ZB125 | 125 | 80 | 1500/3000 | 8/12 | 83 | 25.35 | 2120×1550×1350 | 1800 |

| ZB200 | 200 | 160 | 750/1500/3000 | 4/8/12 | 83 | 57.25 | 2350×2200×1910 | 4000 |

| ZB330 | 330 | 200 | 750/1500/3000/4500 | 4/8/12 | 83 | 81.98 | 2520×2130×2360 | 5000 |

The above are the specific parameters of 6 sausage chopping machines. They have different volume, capacity, size, weight, etc.

Step 4: Seasoning and mixing ( Vacuum mixing machine)

The vacuum mixer is a special machine for mixing meat and seasoning. This machine can isolate oxygen, reduce bacterial growth, increase the amount of protein released, and improve the elasticity and taste of the meat. Under vacuum recompression, the meat is inflated and can be thoroughly mixed with the seasoning. The vacuum mixer is a must-have machine for sausage mixing, which is efficient and easy to operate.

The parameters of the vacuum mixing machine

| Type | Power (kw) | Rotating speed (rpm) | Capacity (kg/h) | Size of the machine (mm) | Weight (kg) |

| BX-50 | 1.1 | 75/67 | 20 | 740*810*775 | 180 |

| BX-100 | 1.5 | 84/42 | 60 | 1200*682*1060 | 240 |

| BX-150 | 1.5 | 84/42 | 120 | 1280*720*1100 | 290 |

| BX-200 | 2.2 | 84/42 | 160 | 1350*820*1350 | 400 |

| BX-300 | 2.4 | 84/42 | 240 | 1750*900*1380 | 510 |

| BX-500 | 4.5 | 84/42 | 400 | 1560*1120*1510 | 650 |

| BX-650 | 6 | 84/42 | 500 | 1650*1300*1650 | 730 |

To be honest, no matter what kind of demand you have for a vacuum mixer, our machine can meet you.

Step 5: Filling the sausage (sausage making machine)

The sausage-making machine is the core machine in the sausage processing line, which can quickly fill the fillings into animal casings, protein casings, and plastic casings. Sausage with a diameter of 16mm, 19mm, and 25mm can be made, and the maximum diameter is 52mm. The machine is made of thickened high-quality stainless steel, with stable running, simple operation, and excellent production.

The parameters of the sausage making machine

| Type | Gross weight (kg) | Net weight (kg) | Power (KW) | Volume (L) | Capacity | Size after packaging | Voltage |

| Sf150 | 140 | 120 | 0.75 | 15 | 300KG/H | 530x410x1350 | 220V/50Hz |

| SF260 | 180 | 160 | 1.1 | 26 | 400KG/H | 600x470x1350 | 220V/50Hz |

| SF350 | 210 | 180 | 1.1 | 35 | 600KG/H | 690x540x1350 | 220V/50Hz |

As the main machine in the sausage production line, we have three sausage maker machines for you to choose from.

Step 6: Knot the sausage (sausage knotting machine)

In the sausage processing line, the sausage knotting machine can quickly knot the sausages into two types, manual and electric. With an advanced machine structure, the casing is not damaged. It eliminates the cumbersome manual knotting and saves labor costs.

Technical parameters of sausage knotting machine

sausage knotting machine

We have 5 manual sausage knotting machines and 4 automatic sausage knotting machines. Refer to the above table for specific parameters.

Step 7:Smoking (smoking oven)

Smoked sausage can be divided into half-cooked and fully cooked. If you want only half-cooked products, you only need to put the sausage at 30-40 ℃ for fumigation. Fumigating sausages can not only give them unique flavor but also kill bacteria. This machine has electric heating and steam heating in two ways, not only can be used for smoking but also can be used for cooking, drying, coloring, and other functions. The well-designed smoking system can evenly distribute the smoke in the furnace, making the meat products evenly colored and beautiful in color. Therefore, you can not only put this machine in the sausage processing line, you can put it in other production lines.

The parameters of the smoking oven

| Type | Size(mm) | The size of the box(mm) | The size of the cart(mm) | Output(kg) |

| 100 | 1650*1200*2200 | 1350*1200*1700 | 970*1040*1220 | 100 |

| 150 | 1700*1300*2400 | 1350*1300*2100 | 900*1000*1500 | 150 |

| 200 | 1700*1200*2600 | 1400*1200*2300 | 1000*1000*1750 | 200 |

| 250 | 1800*1100*3000 | 1500*1200*2530 | 1050*1050*1970 | 250 |

| 500 | 1800*2250*3000 | 1500*2250*2530 | 1050*1050*1970 | 500 |

| 750 | 1800*3310*2900 | 1500*3300*2530 | 1000*1000*1860 | 750 |

| 1000 | 1800*4400*3000 | 1500*4400*2530 | 1050*1050*1970 | 1000 |

From this table, you can know the parameters of each sausage smoking oven. If you have any questions, please contact us and we will reply to you as soon as possible.

Step 8: Packaging (vacuum packaging machine)

Packing is the last step in the sausage processing line. The good sausages need to be packaged. The best way to pack them is to use a vacuum packaging machine. Taking away the air in the package, on the one hand, can inhibit the growth of bacteria in the food, on the other hand, it can also save transportation space. This vacuum packaging machine is suitable for plastic composite film or aluminum foil composite film packaging, which can effectively extend the shelf life of food.

The parameters of the vacuum packaging machine

| Type | sealing length (mm) | The size of the vacuum chamber(mm) | Sealing width (mm) | PowerkW | Packaging capacity | Seal center distance (mm) | Size of the machine | Weight (kg) |

| DZ-400 | 400 | 500×460×110 | 8-10 | 0.8 | 2-3 | 400 | 520×515×910 | 80 |

| DZ-5002S | 500 | 590×506×110 | 8-10 | 1.5 | 2-4 | 420 | 1210×630×850 | 380 |

| DZ-6002S | 600 | 590×540×120 | 8-10 | 2.5 | 2-5 | 500 | 1210×660×900 | 420 |

| DZ-7002S | 700 | 820×705×150 | 8-10 | 2.5 | 2-5 | 520 | 1680×780×1000 | 480 |

| DZ-8002S | 800 | 920×780×220 | 8-10 | 5 | 2-5 | 650 | 1835×910×1060 | 500 |

As the last step of the sausage processing line, the packaging machine is one of the essential machines. Please tell us the sealing length and sealing center distance you want, and we will recommend a suitable machine for you.

What is the cost of a sausage factory?

Discovering the cost of a sausage factory involves considering various factors such as sausage making machine, location, and scale. To determine the precise expenses, it is crucial to assess the size of the facility, the quality of sausage production equipment required, and the geographical location for logistical considerations.

Additionally, operational costs and regulatory compliance should be factored into the overall estimation. By delving into these aspects, one can gain a comprehensive understanding of the financial investment needed for establishing a sausage factory. For detailed and tailored insights into the specific costs associated with your sausage factory venture, consult with industry experts and professionals in the field

Advantages of the sausage processing line?

- All sausage makers are made of high-quality stainless steel with stable operation and excellent production.

- The sausage produced is uniform in size and will not burst the casing.

- Provide the formula for making sausage to meet the requirements for making sausage with different flavors in one production line.

Common problems of the sausage production line

Can this sausage processing line process frozen meat?

you can process fresh meat or frozen meat below – 18 ℃.

Has the sausage processing line been successfully sold abroad?

Of course. Our main market is abroad. American customers have bought our products and are very satisfied with the production line.

Can we make chicken sausage?

Yes. It’s up to you to choose what kind of meat you want.

What should I do if I want to grind the meat finer?

You can add another chopper to grind the meat twice.