This chicken cutting machine is a kind of highly efficient automatic meat cutting equipment, adopting the principle of “variable speed mechanism” and “automatic feeding”. It simulates the manual cutting process, and can quickly process chicken, poultry, ribs, and other ingredients into sections, blocks, dices, and other shapes.

The whole machine is compact and easy to operate, and can process more than 700 kilograms in one hour. Widely used in food processing plants, slaughterhouses, catering central kitchens, supermarkets, and other scenes, it is the ideal choice for small and medium-sized meat processing enterprises to improve efficiency and save labor.

Advantages of chicken cutting machine

- Suitable for fresh or microfrozen meats with a small amount of broken bones. If you need to cut large bones (such as beef bones) can be equipped with another special bone cutter.

- Available in PVC for easy replacement. Or use more durable plate conveyor belt to meet different production needs.

- The machine body is made of stainless steel, rust-resistant and easy to clean. The blades are made of high manganese steel, sharp and durable, with neat cutting effect.

- McNamee wheels can be customized and installed to facilitate the flexible movement of the equipment in the workshop. Simple maintenance, saving labor cost.

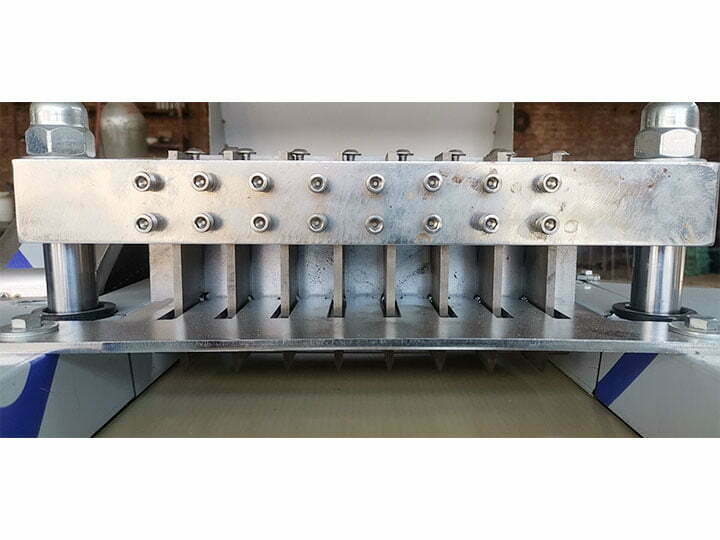

- Equipped with eight cutter discs with adjustable cutting length (15-50mm). Equipped with compact chain to fix the meat block, ensuring the block is intact without slipping.

Application of the chicken cutting machine

The chicken cutting machine takes shape at one time, which is very clean and hygienic. It can be easily disassembled, cleaned, and replaced with different specifications and sizes quickly and conveniently.

This application of the meat cutting machine is very wide. which is widely used in supermarkets, restaurants, markets, small meat processing plants, student canteens, etc. It can cut poultry such as chicken, duck, and goose. also suitable for cutting fish, lamb, beef, etc.

Speaking of fish, we also have an efficient fish filleting machine for sale, so you can also contact us if you need it.

Chicken meat cutting machine main components

The machine consists of a frame, a conveyor belt, a nip roll, a cutting board, and a gear mechanism. The combination cutter can cut chicken, duck, fish, goose, ribs, and many other things into different sizes of blocks, segments, and stripes.

Eccentric wheels can adjust and cut lengths, and the adjustment range is 10-50mm. The cutting tool simulates the principle of manual cutting and feeds the material intermittently using the main and auxiliary crankshaft connecting rods. The processed material has a regular shape, good organization, and no waste, which greatly reduces the labor intensity.

Chicken cutting machine technical parameters

Our chicken slicer can process 400-500kg of meat per hour. The weight of the machine is 250kg and the size is 1300x600x960mm. If you have other needs, please feel free to contact us, we will reply to you as soon as possible and give you reasonable suggestions.

| Output | 400-500kg/h |

| Size mm | 1300*600*960 |

| Power | 220v(3.0kw)/380v(2.2kw) |

| Weight | 250KG |

| Triangular zone | B1016 |

| Conveyor Belt | 310*1500MM |

| Section Length | 15-50MM |

Besides, the price of our poultry cutting machine is also very cost-effective. So far, we have exported our chicken cutting machine to Canada, the Philippines, Malaysia, the USA, Nigeria, India, and other countries. Due to the distance and tax rate, I can’t give you the exact price now. Please contact us for the latest price.

Installation and commissioning

- Place the chicken cutting equipment on a horizontal working site to ensure that the machine works smoothly and reliably.

- Check whether there is foreign matter on the conveyor belt of the chicken cutting machine and clean it up to avoid tool damage. Turn on the power supply to see if the direction of rotation of the motor is the same as that required by the chicken meat cutting machine.

- Try cutting before work, and observe whether the cut specifications are consistent with the requirements. Otherwise, we should adjust the length of the cut pieces to meet the requirements and then work normally.

- The lubricating oil should be added to the oil injection hole before start-up

- Install the tool. First, turn the eccentric wheel to lower the tool holder to the lowest point. After the knife is in contact with the chopping board, tighten the screw. The big knife and the row knife must be parallel. If they are not parallel, the knife will be connected and the knife will be easily broken.

- The knife is fastened to the knife holder, and the cutting force of the knife holder can be adjusted according to the material to be cut. If the strength is too light, it is easy to have a continuous cutting; if it is too heavy, it will easily damage the board.

Tool table adjustment of hen meat cutting machine

After using it for some time, if there is a continuous knife condition, it is generally caused by the wear of the chopping board, and the knife table needs to be adjusted downward.

Adjustment method

Use a wrench to loosen the lock nut on the connecting rod connected to the knife table on both sides of the fish cutter, rotate the lead screw counterclockwise, and the knife table descends; turn the lead screw clockwise to raise the knife table. The range of one adjustment is only one-quarter of a circle.

Section length adjustment

Rotate the eccentric wheel, and make the slider parallel. Loosen the lock nut, and move the eccentric wheel to the opening end, and the cutting block becomes larger; in the opposite movement, the cutting block becomes smaller. After adjustment, lock the lock nut.

Successful cases of the chicken cutter

As a reliable chicken cutting machine manufacturer, KFC has customized an all-stainless steel chicken cutting machine from our company for processing and cutting chicken.

How to maintain the meat cutting machine?

The chicken cutting machine can solve the difficulties of many food factories and improve work efficiency. In addition, it also saves a lot of labor costs. However, the maintenance of the equipment cannot be ignored. The equipment and people must be maintained, it needs you to cherish it carefully, the following is a detailed introduction to the maintenance methods of the chicken cutting machine.

Poor cutting

If it gets slower or difficult to cut, stop the machine check the cutting edge, and sharpen the blade with a sharpener.

Power operation

Unplug the power plug after using it.

Equipment cleaning

You shouldn’t flush the equipment directly with water.

Maintenance tip

Lubricate the swing guide rod weekly, and sharpen the blade with a sharpener.