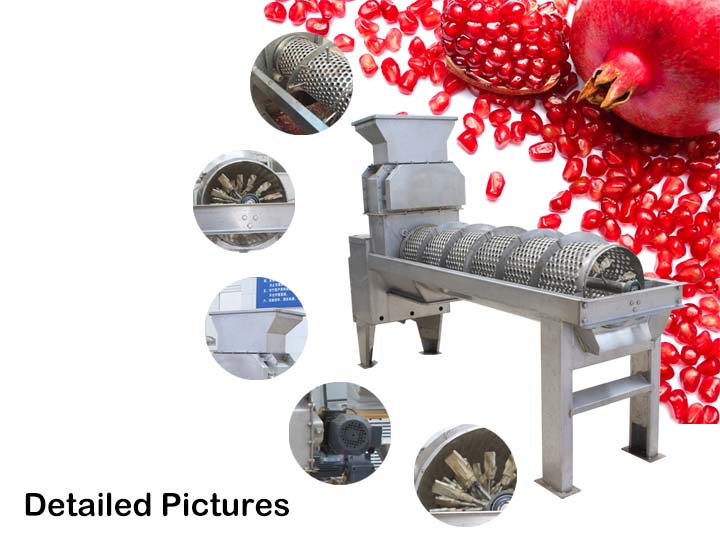

Pomegranate peeling machine is a special machine for deep processing of pomegranate. This machine is manufactured by our company on the basis of absorbing foreign technology. During the working time, it can mimic the method of artificial peeling, and the pomegranate skin and seeds are completely separated by the operation of the machine. What’s more, this machine is divided into a single-layer crushing and peeling machine and a double-layer crushing and peeling machine. It can be widely used in food processing industries such as winemaking and beverage making.

What are the differences between single-layer and double-layer pomegranate peeling machine?

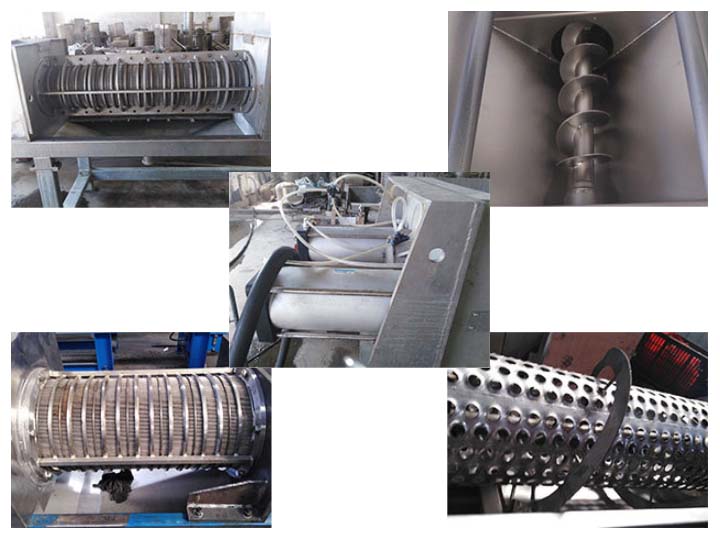

As the name suggests, the single-layer pomegranate seed picking machine has only one layer of the crushing system. The pomegranate processed by this machine only needs to be broken once. The double-layer pomegranate seed picking machine is divided into upper and lower crushing devices. The upper crushing device is a stainless steel blade crushing roll, and the adjustment range of the gap between the two rolls is 20-30 mm. The lower crushing device is a food-grade rubber crushing roller.

Generally speaking, the damage rate of pomegranate treated by single layer machine is low, but the output is small. After two breaks of the double layer, the pomegranate seeds are peeled off more cleanly, so the corresponding yield is increased. However, due to the increased crushing power, the content of the pomegranate yellow film will increase.

How does the Pomegranate peeling machine work?

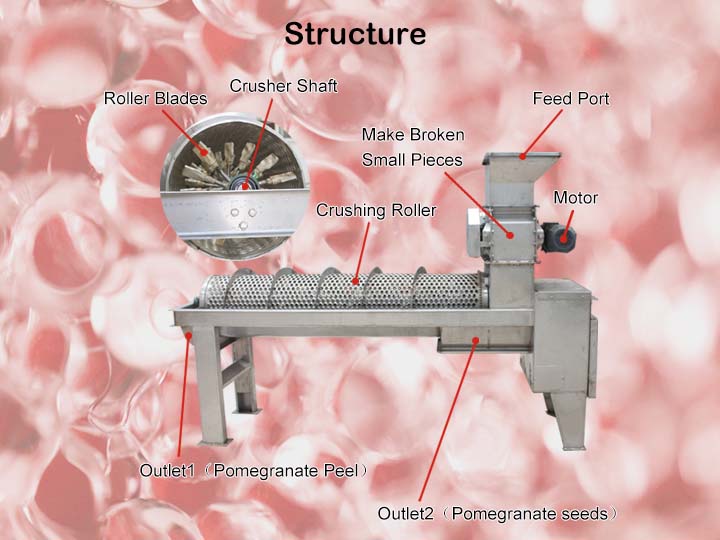

The automatic pomegranate peeler is composed of a crushing system, a separating system, and a frame.

- First, the pomegranate enters the upper crushing system from the hopper (the single-layer machine has only this crushing system). After the relative extrusion of the crushing rolls and the cutting of the blades on the rolls, the pomegranate is cut and divided into several pieces.

- Then enter the lower crushing device for the second crushing. The lower crushing roller is made of non-toxic and high elastic rubber, which has less damage to pomegranate seeds. After two breaks of pomegranate, the skin and seed have been basically separated.

- At this time, the broken pomegranate will enter the separation device. The separating device is equipped with frequency conversion and speed regulation, which is composed of a rotating screen and a separating shaft. Under the rotating action of separating shaft and rotating screen, pomegranate seeds and part of juice leak out from the sieve hole, enter the next technological process through the outlet port (conveyed to the juicer or other machines by screw pump); pomegranate peel is discharged from the tail of the pomegranate peeling machine.

Advantages of pomegranate peeling machine/pomegranate seed picker :

- Pomegranate seed picker can replace manual peeling and greatly improve production efficiency.

- Except for the reducer and some transmission parts, the whole machine to peel pomegranate is made of high-quality stainless steel. It meets the food safety and hygiene standards.

- The clearance between crushing rollers can be adjusted. It meets the requirements of peeling and seed picking for different varieties of pomegranate.

- The quality of the pomegranate seeds taken out is good, the fruit grain integrity rate is ≥90%, and the fruit grain contains impurities ≤6%.

- High work efficiency, the output can reach 1-5 tons per hour.

- Pomegranate peeling machine runs stably, with low noise and low energy consumption.

- There are sieve holes on the rotary sieve. The diameter of the holes can be chosen freely. Selection range 12-18 mm. If the variety of pomegranate is special, it should be noted when ordering.

Pomegranate peeling machine Technical parameters :

| Type and output | Size (mm) | Weight (kg) | Rotary sieve diameter(mm) | Total power consumption(kw) |

| Single-layer 1-1.5T | 2600*625*1750 | 350 | 350 | 3.3 |

| Double-layer1-1.5T | 2600*625*2100 | 400 | 350 | 3.3 |

| Single-layer 3-4T | 2700*880*1920 | 600 | 500 | 5.2 |

| Double-layer3-4T | 2700*80*2230 | 700 | 500 | 5.2 |

| Single-layer 5T | 2700*880*2250 | 1200 | 800 | 7.7 |

| Double-layer5T | 2700*880*2565 | 1400 | 800 | 7.7 |

This is the specific parameters of single-layer pomegranate peeler and double-layer pomegranate peeler. From this table, you can see the size, weight, rotating screen diameter and power consumption of the machine.

FAQ:

- Can we adjust the cutter of the pomegranate peeling machine?

A: It can be adjusted. Depending on the size of the pomegranate and the variety, the distance between the cutters can be adjusted. The adjustment range is 5-15mm.

- Can we adjust the rotation speed of the sieve barrel?

A: The screen barrel is controlled by frequency conversion, and the speed can be adjusted.

- Are there any requirements for the raw materials to be cut?

A: The size of the pomegranate should be as similar as possible, otherwise it will affect the peeling effect. Also pomegranate should be fresh.

- Why is the pomegranate peeled and the seeds pick not clean?

A: On the one hand, it may be that the cutter distance adjustment is too large. On the other hand, it may be because the pomegranate is not fresh and the storage time is too long.

- Is the automatic pomegranate peeler made of 304 stainless steel? Can you make 316 material?

A: Generally speaking, the machine is made of 304 stainless steel. But if you have special requirements, we can customize it for you.