The industrial popcorn making machine is also called a popcorn making machine, it is a special machine for making popcorn. This machine can be used to make different flavors of popcorn. Popcorn is sweet and crisp,and it is popular with children and the elderly. Therefore, it has a good marketing prospect. The machine covers a small area and is easy to operate. The products manufactured are suitable for sale in cinemas, supermarkets, food streets, amusement parks, residential districts, primary and secondary schools, etc.

Instructions for Use of American Spherical Industrial Popcorn Making Machine

Need to know before use

- Remove the machine from the packing box and place it on the stable ground.

- Minors are prohibited from operating this product.

- The gas bottle should be 1 meter away from the machine during operation.

- This machine should be equipped with a high-pressure valve, otherwise, the machine cannot be operated.

- When operating this machine, the onlookers and customers should be at least 1 meter away from the machine.

- Handle gently during transportation.

- This machine should be placed in a cool and ventilated place.

- The automatic popcorn maker should be cleaned without using the machine for a long time.

Machine installation

- Unpack and assemble the machine, check to make sure the assembly is correct.

- Connect the liquefied gas and connect the power supply (Note: the manual machine has no power supply); check to make sure the connection is correct.

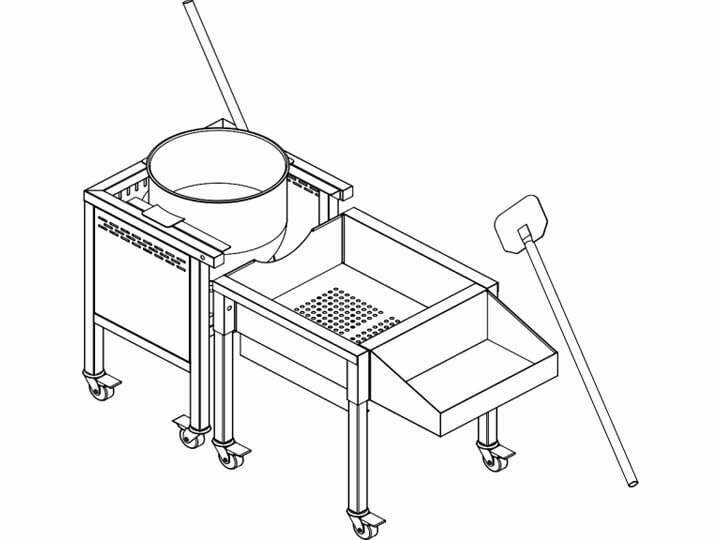

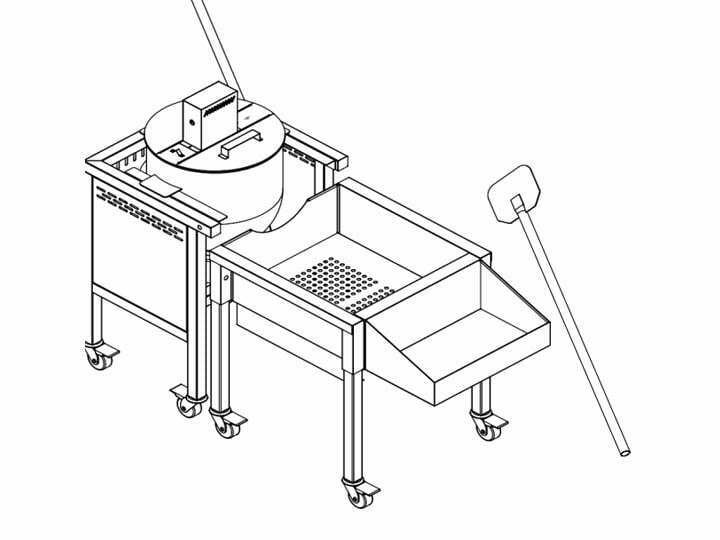

How to use a industrial popcorn making machine

- Preparation of raw materials: popcorn coconut oil (400 grams for large machines, 250 grams for small machines); special varieties of corn (500 grams for large machines, 300 grams for small machines); anti-caramel (400 grams for large machines, 250 grams for small machines)

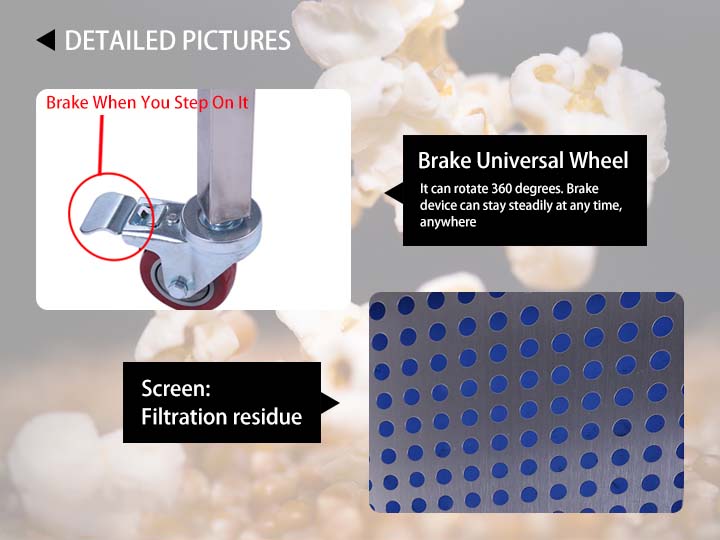

- Start the machine: Turn on the automatic mixing switch (note: manual machine does not mix), ignite the liquefied gas stove of the machine, and adjust the firepower to a moderate level.

- Add raw materials: After the machine is ignited, pour the prepared oil into the pot. When the oil is heated to high temperature, throw 3 or 4 corn kernels into the pot until the corn kernels burst. Put the prepared corn into the pot and add the prepared anti-caramel.

- Start stir-frying corn: The automatic machine needs to cover the pot cover so that the machine automatically stirs. The manual machine needs to be stir-fried with a large popcorn spade until the popcorn pops completely.

- Finish making popcorn: About a minute or so, the pot began to make a fierce popping sound. After that, the popping sound gradually disappeared. Immediately close the fire and pour the popcorn on the sieve table. Finally, the popcorn is continuously stirred until it is cooled.

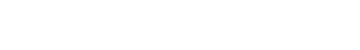

detail information of popcorn maker popcorn maker detail information detail information of popcorn poper popcorn making equipment detail information

Parameter of Popcorn Making Machine

Manual spherical American commercial popcorn machine

| Name | Type | Size(CM) | Heat Method | Voltage/Power | Output |

| Small manual popcorn machine | HX-PM01 | 135*52*102 | Liquefied gas | – – | 1-1.5KG |

| Large manual popcorn machine | HX-PM03 | 150*64*110 | Liquefied gas | – – | 1.5-2KG |

(Manual commercial popcorn machine does not have a motor)

This is the parameter of large and small manual popcorn machines, and the output is 1-1.5kg and 1.5-2kg respectively

Automatic spherical American popcorn machine

| Name | Type | Size(CM) | heating method | Voltage/Power | Output |

| Small automatic popcorn machine | HX-PM02 | 135*52*102 | Liquefied gas | 12V/45W | 1-1.5KG |

| Large automatic popcorn machine | HX-PM04 | 150*64*110 | Liquefied gas | 12V/45W | 1.5-2KG |

This is the parameter of large and small automatic american popcorn machines, and the output is 1-1.5kg and 1.5-2kg respectively. Compared with the manual popcorn machine, this fully automatic machine is simple to operate and saves labor.

Maintenance and Cleaning of the Commercial Popcorn Machine

- After the popcorn is out of the pan, pour a proper amount of water into the pan. Turn on the auto-mix button and let it automatically stir for a few seconds. Manual mixing is required for manual machines. Pour out the water after cleaning.

- Turn off the automatic stirring switch, which is not available for manual machines. Clean the inner pot with a non-corrosive semi-dry wipe. Do not wash the inner pot with metal hard objects to avoid wear and affect the machine.

- When the machine is not in use, turn off the power and unplug the plug. The manual machine does not have this operation. Then disconnect the gas valve and clean the parts of the fuselage with a non-corrosive semi-dry wipe to keep the machine clean.

- The industrial popcorn machine should be stored in a cool and dry place with ventilation.

Transportation and Storage of Industrial Popcorn Making Machine

This device should be handled with care to prevent violent collisions and must not be inverted. Generally, it should not be stored in open air for a long time. It should be placed in a warehouse with good ventilation and no corrosive gas. It should be waterproof and sun-proof when it needs to be temporarily stored in the open air.

Fault analysis and troubleshooting

- Fault phenomenon: Popcorn maker stir bar does not stir.

- Solution

1 Check that the circuit connections are properly energized.

2 Check if the motor is burnt out. If it turns out, you need to replace it with a new one.

- Fault phenomenon: the ignition switch does not catch fire or the ignition effect is not good.

- Solution

1 Check if the gas valve is a high-pressure valve, do not use a low-pressure valve.

2 Do not act too fast when you are on fire.