The screw press machine is a high-efficiency, widely used commercial equipment for the dewatering of fruit and vegetable juices (apple, grape, ginger, etc.) and fiber-containing materials. The equipment has a reasonable structure and adopts advanced screw extrusion technology, which can achieve 90%+ juice yield in a single machine.

We have a variety of single screw, double screw and special screw models, which can flexibly meet the production needs of different customers. Read on to find out how it can help you achieve efficient production with ease!

Method for judging material dryness (water content)

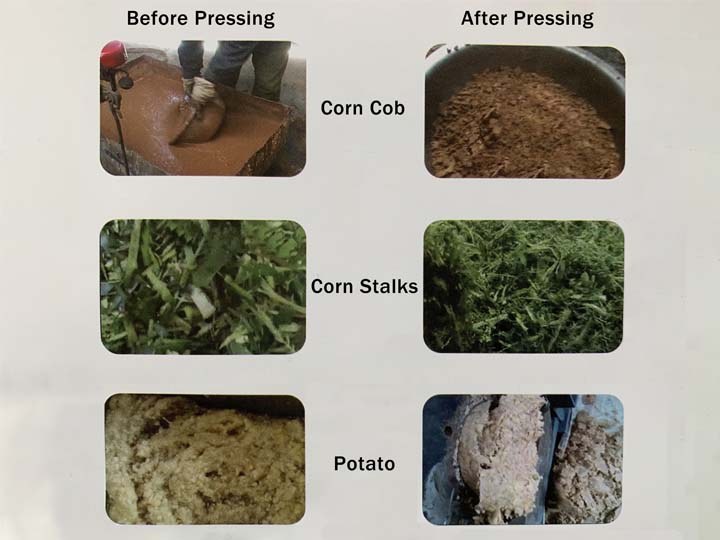

Due to the different requirements of material properties, particle size, density, and dryness, the application scope of the screw press machine is slightly different. The properties, granularity, and density of materials are certain. So, how to judge the dryness requirement of materials?

- Water content is about 60%: hold the material hard with your hand, and you can’t hold the water.

- Water content is about 70%: hold the material hard by hand. There is water between fingers, but it won’t drip.

- About 80% water content: hold the material with your hand, and the water can flow down.

Double screw press machine

Working principle and classification

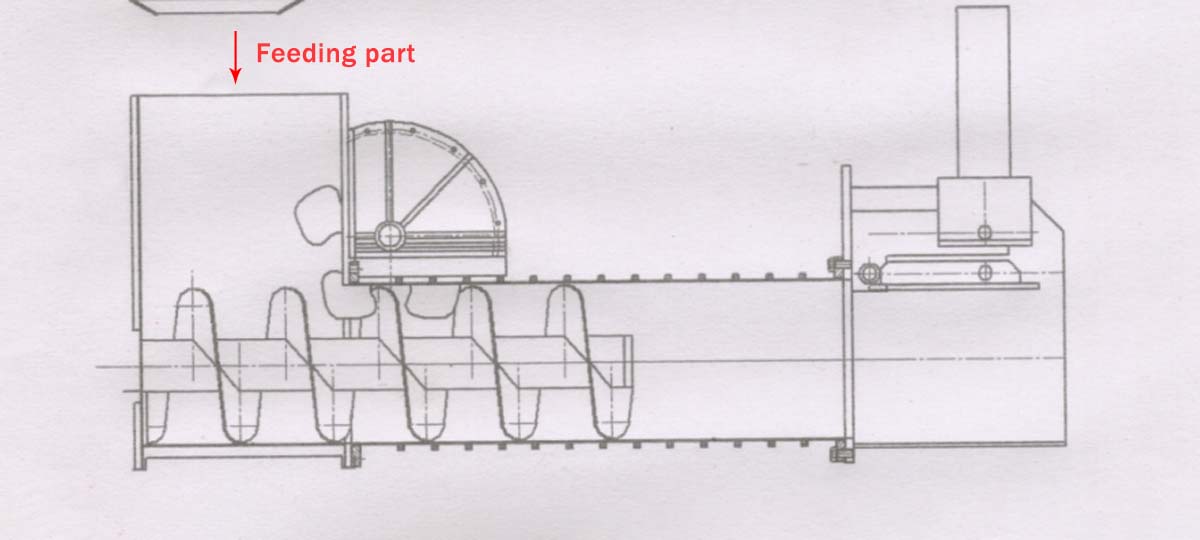

The double screw juicer is equipped with two screws. According to the screw arrangement, it can be divided into parallel double screw juicers and tandem double screw juicers. You can flexibly choose different screw forms according to the material characteristics and output requirements to achieve the ideal pressing effect.

Parallel twin screw juice extractor

- The left and right screws rotate in opposite directions and are located on different main shafts.

- Fast rotating speed, prone to clogging at the outlet, high cost, and relatively outdated technology.

- This model is mostly used for poultry meat separation and meat fiber separation, and is no longer the mainstream choice in the fruit and vegetable industry.

Tandem type double screw juicer

- Conveying screw and pressing screw are arranged in series, rotating in the opposite direction, with simple structure and low cost.

- It is especially suitable for pressing fruits and vegetables containing certain fibers, such as grape pomace and other materials in the winemaking industry.

- This model is the most cost-effective press at present, but the output and efficiency are relatively low, and the material requirements are high.

Scope of application and limitations

The double screw press machine is suitable for juicing highly fibrous fruits and vegetables such as grape skin pomace, sea buckthorn berries, fermented ginger, etc. with excellent results.

Not applicable to:

- Materials with a lot of fluid and slippery texture.

- Fruits and vegetables with high sugar content whose particles are less than 10mm.

- Chinese medicine dregs, root and stem coarse fiber materials with particles larger than 10mm.

Double-screw press machine parameters

| Type | ZKY-S1.5 | ZKY-S5 | ZKY-S10 |

| Production capacity(t/h) | 1.5 | 5 | 10 |

| Size(mm) | 1900*600*1200 | 3500*1000*1300 | 3750*960*1300 |

| Power(kw) | 7.5 | 7.87 | 11.37 |

Single screw press machine

Working principle

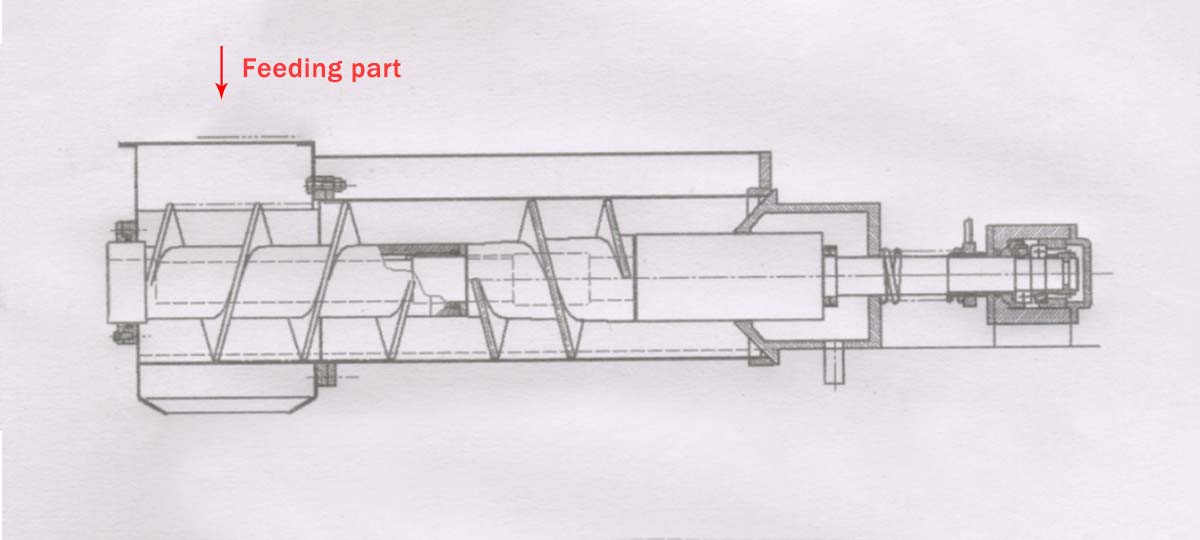

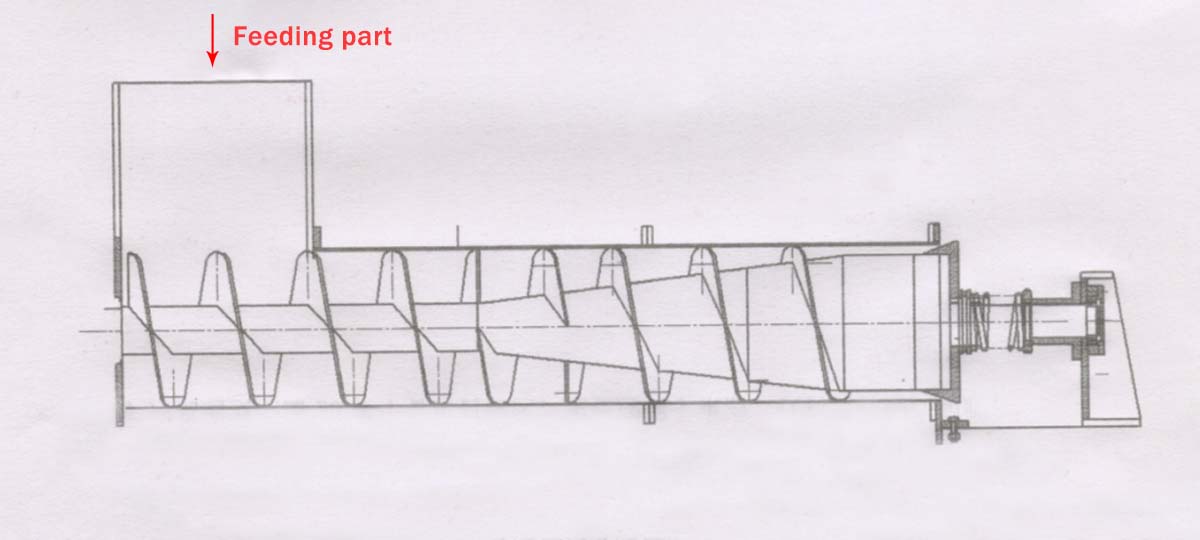

The single screw press machine consists of frame, transmission system, feeding part, juicing part, hydraulic system, protective cover and electric control part. It utilizes spindle screw, sieve drum and pressing door to form pressing layer to realize dewatering.

- After crushed, the material enters into the feeding box and is pushed into the pressing chamber by the forced feeding plate.

- The extracted juice flows into the juice receiving tray through the sieve drum, and the residue after pressing is discharged through the forced discharge door at the end of the sieve drum.

When opening the forced discharge door, it is necessary to pay attention to the degree of dryness of the discharged residue. If the waste residue is too dry, it may cause the machine to clog.

Scope of application

- Suitable for all kinds of fruits and vegetables containing fiber, such as fresh grapes, fermented grapes, sea buckthorn fruit, pineapple, etc.

- Suitable for medicinal herb residue (not suitable for materials that produce sticky and slippery after fermentation).

- Suitable for dehydration of plant stalks and roots, such as corn stalks.

- Suitable for dewatering unfermented garbage from vegetable market.

- Suitable for medical plastic waste.

- Suitable for 100% fiber pulp residue, coarse (cotton) fiber black liquor extraction.

Machine advantages

- Adopting German gear transmission technology with high torque, low noise and scientific physical extrusion process.

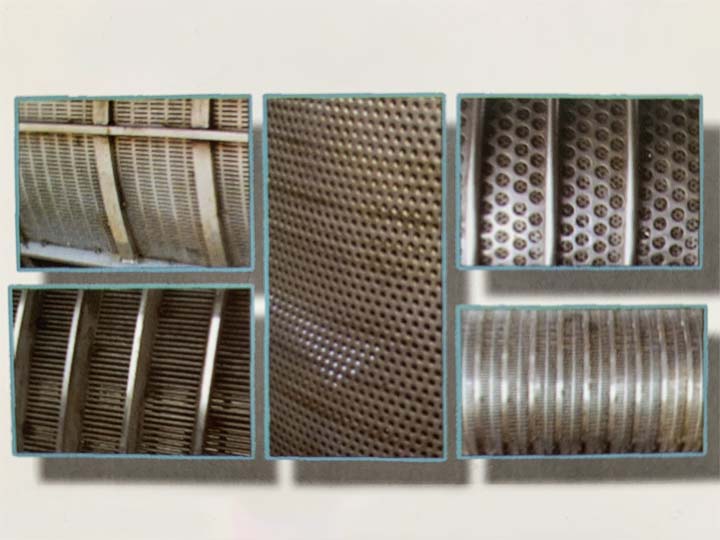

- The sieve drum adopts trapezoidal wire mesh with external reinforcement, which is divided into detachable type (easy to dismantle and clean) and integral type (stronger pressure-bearing).

- Equipped with forced feeding plate to enhance the feeding speed and effectively prevent the material from slipping back.

- Uniform discharge, wet and dry. For materials with high moisture content and the diameter of sieve drum is more than 500mm, it is recommended to use special screw press.

- This screw press machine has the characteristics of high pressing strength, high pressure, not easy to deform, not clogging, etc. It is corrosion-resistant, abrasion-resistant, easy to maintain, and has a long service life.

Single screw press machine parameters

| Production capacity (t/h) | Hydraulic system pressure (Mpa) | Motor power (KW) | Weight

(KG) | Size

(mm) |

| 1.5 | 1-5 | 4 | 800 | 2565*480*905 |

| 3 | 1-5 | 4 | 1200 | 3200*560*1120 |

| 5 | 2-6 | 7.5 | 2000 | 4100*900*1500 |

| 10 | 2-8 | 15 | 2500 | 4620*920*1550 |

| 20 | 2-8 | 18 | 3000 | 4950*1100*1730 |

| 40 | 2-10 | 22 | 4500 | 6000*1200*2000 |

Special screw press machine

Brief introduction

- The special screw press machine, also known as screw dehydrator, screw press or variable diameter screw juice extractor, combines the advantages of both single and double screw juicers.

- By varying the aperture of the screen drum, the shape of the auger and the speed of rotation, the machine can efficiently process viscous and slippery fluid materials and achieve excellent dewatering results.

- It is particularly suitable for smooth and viscous materials containing gelatinous proteins, oils, and fats, and meets the requirements of almost all industries involving “solid-liquid separation” processes. The water content of the dewatered material can be as low as ≤60%.

Scope of application

- Fruit and vegetable materials: suitable for juicing and dehydration of roots, stems, leaves, flowers, fruits and other parts, such as red dates, apples, pears, sweet potatoes, potatoes, pineapples, begonia fruits, blueberries, sea buckthorn fruits and sea buckthorn with branches, etc.; flowers, such as peonies, roses and so on.

- Dewatering of all kinds of waste residues: including coconut, medicine dregs, tea dregs, vinegar dregs, wine dregs, cassava dregs, coffee dregs, corn husk dregs, fish dregs, shrimp dregs, chicken feathers, chicken residues and so on.

- Food waste and organic waste separation: suitable for solid-liquid separation of kitchen garbage, domestic garbage, vegetable market garbage, as well as fermentation of kitchen garbage, biogas residue, separation of organic and inorganic materials, etc.

- Livestock and poultry manure dewatering: suitable for solid-liquid separation of pig manure, cow manure, duck manure and other manure.

- Other special applications: such as dewatering and recycling of sludge residue, pulp residue, medical plastic and gelatin residue.

Machine advantages

- The internal screw structure can prevent the material from flowing back and at the same time play a slight crushing role, realizing the integration of crushing and pressing, saving space and investment.

- The screw adopts double-blade pushing type, with smooth feeding, even wet and dry, and fast pressing speed.

- According to the material condition, this screw press machine can be designed with multi-stage tandem screws to realize more thorough and gradual pressing and dewatering.

- When the screw diameter exceeds 500mm, internal agitator is installed to avoid the phenomenon of uneven dry and wet inside and outside.

- According to the need, steam, hot water, solvent, ethanol, etc. can be passed inside the machine to realize more efficient dewatering.

- Auxiliary materials (such as lime, alum, gypsum, corn husk, rice bran, etc.) can be added to help separate the combined water and realize more thorough dehydration.

- The screen has self-cleaning function, which is not easy to be clogged and reduces the need for maintenance.

- Few wearing parts, low maintenance cost. With the continuous improvement of technology, some models can be used for 8 years with almost no maintenance.

- The screen drum adopts stainless steel trapezoidal screen, which has high strength, wear and corrosion resistance, long service life and excellent filtration performance.

Special screw press machine parameter

| Production capacity (T/H) | Motor power (kW) | Weight (kg) | Size (mm) |

| 0.8-1 | 4 | 230 | 1950*510*740 |

| 1.5 | 7.5 | 1200 | 2400*600*1100 |

| 3 | 15.5 | 2400 | 4100*850*1500 |

| 5 | 18.5 | 3000 | 4900*920*1700 |

| 10 | 22 | 3700 | 5200*1000*1870 |

| 20 | 30 | 5000 | 6500*1200*2000 |

If you are looking for efficient, durable juicing and dewatering equipment for a wide range of materials, our screw press machines are undoubtedly the ideal choice for you.

With rich industry experience and advanced manufacturing technology, we can customize the most suitable solution for you, and there are many other models of juicers(such as Commercial Fruit Juice Machine | Fruit Juice Processing Equipment) for you to choose from. Feel free to contact us for more details or a free consultation!