The automatic vegetable dicing machine is designed with composite knives to achieve precise molding of root vegetables (potatoes, carrots, bamboo shoots, etc.) ±0.1mm grade cubes/rectangles.

It can realize a super high capacity of 2000kg/h, and produce finished products with a smooth cutting surface and a high molding rate. The body is made of aluminum-magnesium alloy and food-grade stainless steel, which is not only beautiful and corrosion-resistant but also meets the strict hygiene standards.

The cutting size is adjustable from 3-100mm. Whether it is used in quick-freezing, dehydrating or marinating production line, it brings more stable and high-yield dicing solution for your factory by virtue of low energy consumption, high efficiency and easy operation.

Parameters of vegetable cutting machine

- Production capacity: 1000KG/H

- Motor model and power: Y802-4, 380V/0.75kW

- Dimensions: 710X 660X 1085mm (length x width x height)

- Machine weight: 100kg

- Cut vegetable specifications: cut cubes or cuboids of 4, 5, 6, 8, 10, 12, and 15mm, or make other sizes of tools according to requirements.

How does the vegetable dicing machine work?

Structural features

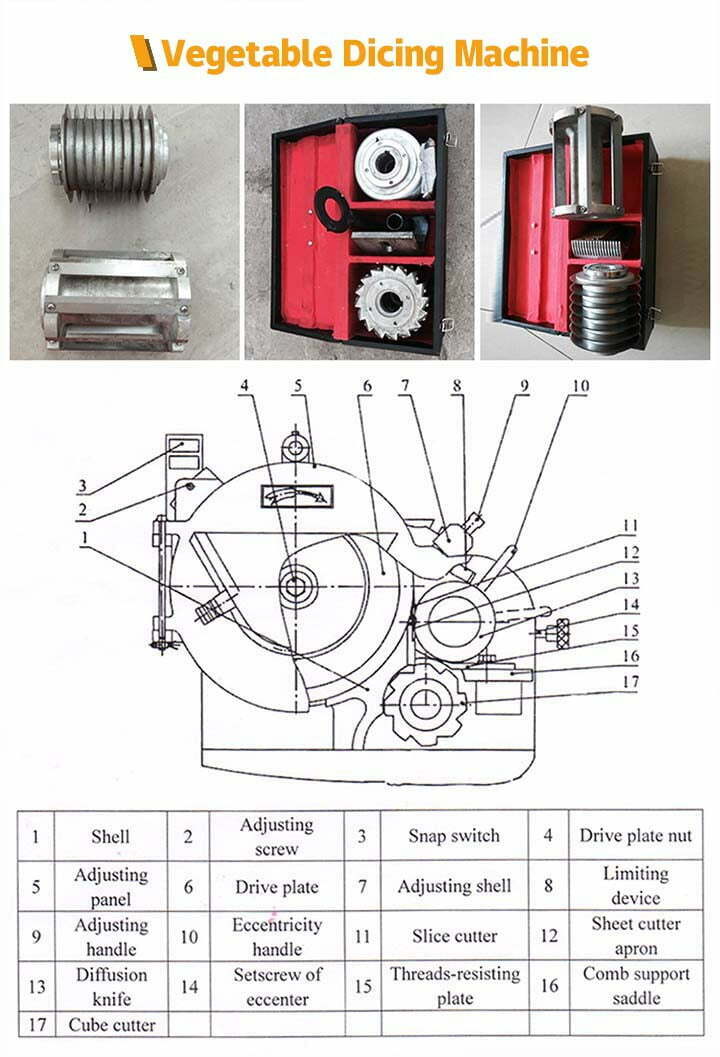

- Frame and shell: made of aluminum-magnesium alloy and food-grade stainless steel to ensure corrosion resistance, easy to clean and meet hygiene standards.

- Feeding hopper: slanting mouth design, easy for batch vegetables to be evenly discharged.

- Dial (turntable): combined with dial cover, driven by motor for high speed rotation.

- Vertical cutter assembly: fixedly mounted inside the casing, used to cut vegetables into thin slices along the radial direction.

- Disc cutter: fitted with a number of round steel wires, used to cut thin slices into uniform strips.

- Horizontal cutter assembly: placed horizontally underneath the dial to cut vegetable strips into desired dices or cubes.

- Transmission system: motor + belt (or gear) + dial shaft, providing rotating power.

- Electric control system: contains start-stop button, emergency stop switch and optional stepless speed control.

Working principle(five steps)

- Vegetables are slid from the feed hopper into a rotating dial, which uniformly orientates the vegetables by means of satin grooves or tabs.

- When the dial rotates at high speed, the vegetables cling to the vertical cutter under the effect of centrifugal force and are instantly cut into slices of uniform thickness.

- The slices continue to move on the dial, passing through the disc julienne cutter, where multiple wires simultaneously split the slices into equal width strips.

- Strips of vegetables fall into the transverse cutter area by gravity or guiding device and are cut off by the transverse cutter, resulting in uniformly sized diced or rectangular pieces.

- The diced vegetables are automatically discharged from the end of the machine and can be directly transferred to the next process (e.g. quick-freezing, dehydrating or marinating).

It is important to note that the material to be cut should be cleaned and mixed before applying the vegetable dicing machine. If the material to be cut is mixed with sand and dirt, the blade edges and blades are easily damaged and dulled. The maximum cutting diameter of the material should not exceed 80mm.

Vegetable dicing machine highlight advantages

- The composite tool design realizes the three-stage processing of “vertical knife→shredding→horizontal knife”, which can be completed at one time, without the need of several times of overfeeding.

- Smooth cutting surface, uniform size of cubes/rectangles, high yield, meet the requirements of subsequent processes such as quick-freezing, dehydrating and marinating.

- Motor directly drives dial + knife set, low energy consumption, stable speed, cutting efficiency can reach thousands of kilograms/hour.

- The vegetable dicing machine body, feeding hopper, and all contact parts are made of aluminum-magnesium alloy and stainless steel, corrosion-resistant, easy to clean, and in line with health standards.

- Compact structure, fast disassembly and assembly, speed regulation and knife change without professional tools, low daily maintenance costs.

Fault analysis and troubleshooting

| Fault phenomenon | Cause Analysis | Exclusion method |

| Low work efficiency of vegetable slicer machine | Ordinary V-belt is loose and slippery at work. | Tighten common V-band. |

| Material not falling | 1. The distance between the comb knife-edge and spacer ring is too large. 2. Slice thickness is too thick. | 1. Re-adjust the position of the comb so that the comb is close to the surface of the separator ring. 2. Adjust the slice thickness so that the slice thickness is consistent with the position of the comb. |

| Material not cut | 1. The rotation direction of the disc is not in accordance with the specified direction.

2. Blockage of the comb. 3. Disk cutting tool is loosened in operation. 4. The vertical knife is blocked by material. | 1. Adjust the turning wheel to clockwise direction.

2. Clean the comb. 3. Fastening disc cutting tool combination. 4. Clean up the leftovers at the vertical knife |

| When cutting fiber materials, there is a constant phenomenon of cutting. | 1. The disc cutter is not in the plate groove of the vertical cutter. 2. Serious wear of the disc cutter. | 1. Adjust the disc cutting tool combination so that it is located in the plate groove about 1 mm. 2. Check whether the round cutter is normal or worn seriously, and then grind or replace it. |

Our vegetable dicing machine has been successfully exported to Botswana, the Philippines, the USA, Mexico, Canada, and other countries. In addition, our factory also provides a full set of fruit and vegetable processing equipment, such as a multi-functional vegetable cutting machine, covering the whole process of washing, cutting, and sterilizing. Welcome to browse our website for more product details, or directly leave a message online, our professional team will recommend the best solution for you!