The yogurt production line (yogurt processing machines) is a fully automatic production line composed of multiple machines. This production line takes fresh milk as raw material and has been treated by pasteurization and fermentation. The yogurt produced by this production line has a unique taste and rich nutrition. As we all know, yogurt is a kind of healthy food, which has great benefits for the human body. So what are the benefits of yogurt compared to fresh milk?

Advantages of yogurt

- Yogurt contains almost all the nutrients in milk, and after fermentation, the nutrition is more abundant.

- After fermentation, the lactose in the milk is decomposed in large amounts, reducing the possibility of lactose intolerance.

- In the process of making yogurt, milk is homogenized, macromolecular fat, protein is decomposed into small molecules, which is more conducive to human body absorption.

- Yogurt contains a large number of active probiotics, which is beneficial to regulate the balance of the bacterial flora in the body. The lactic acid produced after fermentation can also inhibit the proliferation of harmful microorganisms, promote digestion and absorption, and improve gastrointestinal function.

How to make yogurt by this yogurt production line?

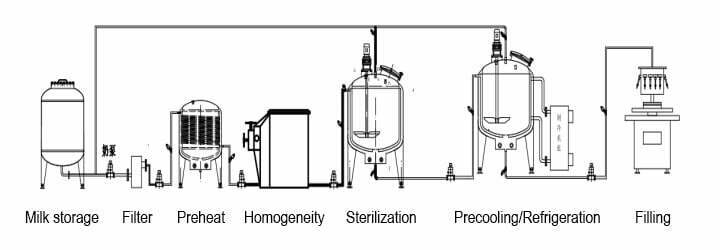

The technological process of making yogurt is as follows

Low temperature storage of fresh milk – filtration – preheating – homogenization – sterilization – pre-cooling /refrigeration – fermentation – filling

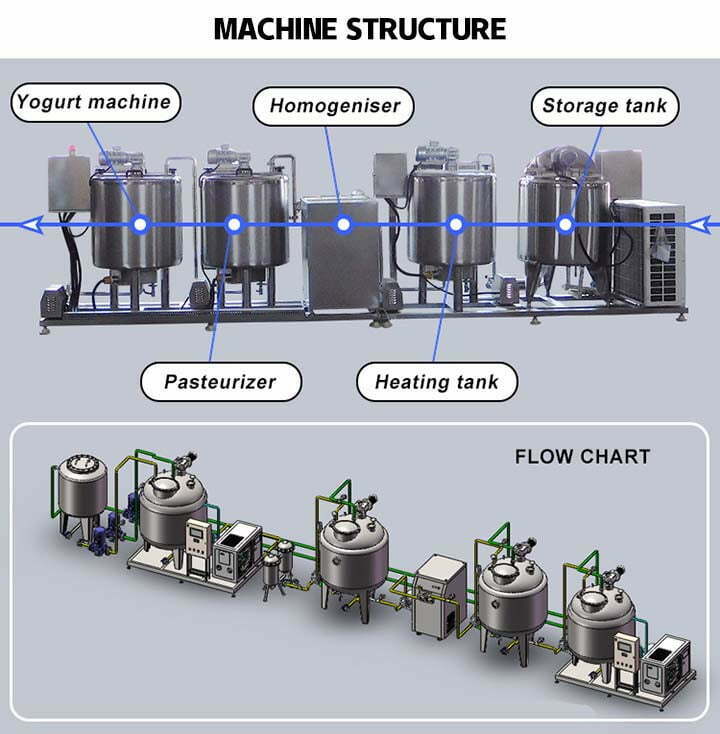

Supporting equipment in the yogurt production line

Storage Tank – Milk Pump – Single/Double Filter – Milk Pump – Preheating Tank – Milk Pump – Homogenizer – Milk Pump – Sterilizer – Milk Pump – Pre-cooling/Refrigeration Tank (Fermentation Machine) – Milk Pump – Filling

Video: the operation of the yogurt production line

Milk sterilization method

Pasteurization

Also known as low-temperature sterilization and cold sterilization. This method is to kill pathogenic bacteria in milk at low temperatures for a long time and preserve probiotics beneficial to the human body. Generally, the milk is heated to 62-85 ° C for 30 minutes. Using this method, it can kill various growth-type pathogenic bacteria in milk, and the sterilization efficiency can reach 97.3%~99.9%. After disinfection, only some thermophilic bacteria, thermotolerant bacteria, and spores remain, but most of these bacteria are lactic acid bacteria. Lactic acid bacteria are not only harmless to people but also beneficial to health. It can be preserved for about a week and needs to be refrigerated. The temperature range is about 2 – 6 degrees Celsius.

Ultra-high temperature instantaneous sterilization

This method is to heat milk to about 135-150 degrees Celsius for 4-15 seconds and then cool it quickly. The bactericidal time required is shorter and the bactericidal efficiency is higher. Because all microorganisms in milk die, they can be stored at room temperature for up to 3 months.

The pasteurization method is used in this yogurt production line. Studies have shown that no matter what kind of heating method will damage the water-soluble vitamins and proteins in milk. During the heating process, about 10% to 20% of the B group of vitamins and about 25% of the vitamin C will be lost. In general, the higher the heating temperature, the more serious the loss of nutrients. There is a kind of whey protein with high nutritional value in the milk. About 10% of whey protein denatured during pasteurization, while 70% of whey protein denatured during ultra-high temperature pasteurization. Therefore, pasteurized milk with low-temperature sterilization has a higher nutritional value.

The production process of the yogurt production line

Step 1: Refrigeration (Milk Tank)

The milk storage tank is mainly composed of the tank body, the heat preservation layer, the American Copeland compressor, the stirring device, and the control panel, and the storage temperature is 3-6 degrees Celsius. This machine is controlled by a microcomputer and can reach the cooling time in a short time. The programmed automatic control unit can automatically start or stop when the milk reaches the set temperature, effectively preventing the deterioration of fresh milk. The thermal insulation layer is filled with polyurethane foam with small thermal conductivity, so it has a lightweight and good thermal insulation effect.

Parameters of the refrigerated tank

| Size mm | 1700*900*1550 |

| Unit name | American Copeland |

| Unit power | 3P |

| Total power | 2.6kw |

| Cooling capacity | 6600 kcal/hour |

| Refrigerant | R22 |

| Thermal insulation performance | ≤1℃/3h |

| Mixer speed | 36r/min |

| Mixer power | 0.75kw |

| Voltage | 380V/50hz |

| Material | 304 stainless steel |

| Thickness | Liner 2mm, Refrigeration Plate 0.9mm, Outer Skin 1.2mm |

| Insulation Materials | Polyurethane foaming liquid |

Step 2: Filtration (single/double filter)

Single/double filters are mainly used to remove large impurities in milk. Usually, these impurities are caused by human activities, such as hair falling in milk barrels when milking, hay falling from cowsheds, feed floats, etc. The double filter is suitable for larger output, the quality of filtered milk can reach 100 mesh. The machine has the characteristics of strong circulation ability, good sealing, and a high filtering effect.

Filter parameters:

| Filtration area | Filtration capacity | proper temperature | Filtration screen aperture | Internal and external surface treatment |

| 0.1㎡ | 0.5-3T | <120℃ | 80-200

mesh |

Internal matte |

| 0.15㎡ | 1-5T | External polished mirror |

Step 3: Preheating (Preheater)

The filtered milk enters the preheater directly through the milk pump and reaches 40 to 50 degrees Celsius in this machine. The machine has three layers, the outermost layer is the insulation layer, which is electrically heated. Before the start of preheating, first, check the water level of the preheater interlayer and reach the visible position of the water sight glass. Then turn on the electric control box (set the water temperature to 60 degrees Celsius, the milk temperature is 45 degrees Celsius), turn on the power switch, turn on the heating, and stir. After the milk temperature reaches 45 degrees, the alarm is completed, the warm-up is completed, and the heating is turned off.

Parameters of the preheater

| 300L preheating / sterilization / fermentation parameters | |

| Size(mm) | 1200*1000*1650 |

| Tank diameter | 800mm |

| Tank height | 600mm |

| Material | 304 stainless steel |

| thickness | 2mm |

| Mixer speed | 36r/min |

| Heating area | 1.6 |

| Mixer motor power | 0.55kw |

| Logistics import and export | DN40 |

| Voltage | 380V/50hz |

| Power | 18kw |

Step 4: Homogenization (homogenization machine)

The milk homogenizer is also called the high-pressure homogenizer. Homogenization is the key to determining the quality and taste of the milk. The high-pressure homogenizer is mainly used for homogenization and emulsification of liquid materials with a viscosity lower than 0.2 Pa.s and a temperature lower than 80 °C. The working principle is that the processed material is sent to the homogeneous valve in the form of high pressure through the reciprocating motion of three plungers so that the material is subjected to the compound force at the moment of flowing through the tiny gap between the disc and the valve seat. The original rough milk is processed into a very fine, uniform and stable emulsion, the average emulsification fineness is less than 1um, and the average particle size of solid dispersion is less than 2um. Homogeneous milk fat globules become smaller, and fully dispersed in milk, not only can prevent fat adhesion and coagulation, but also more conducive to human absorption.

Homogenizer parameters

| 500L homogenizer parameters | |

| Flow | 500L/h |

| greatest pressure | 25mpa |

| Work pressure | 20mpa |

| Motor power | 4kw |

| Size (mm) | 1010*616*975 |

| Voltage | 380V/50hz |

| Material | 304 stainless steel |

Step 5: Sterilization (sterilization tank)

In the yogurt production line. Sterilization is an effective means to extend the shelf life of fresh milk. Before sterilization, it is also necessary to ensure that the water level of the sterilizer is at the water level mirror. Set the sterilization temperature (usually 85 degrees Celsius). Turn on the sterilization heating button, the machine starts sterilization, stir, and the machine will automatically alarm when the sterilization temperature is reached.

Parameters of the sterilization tank

| 300L preheating / sterilization / fermentation parameters | |

| Size(mm) | 1200*1000*1650 |

| Tank diameter | 800mm |

| Tank height | 600mm |

| Material | 304 stainless steel |

| thickness | 2mm |

| Mixer speed | 36r/min |

| Heating area | 1.6 |

| Mixer motor power | 0.55kw |

| Logistics import and export | DN40 |

| Voltage | 380V/50hz |

| Power | 18kw |

Step 6: Pre-cooling / cooling, fermentation (fermentation machine)

After the sterilization is completed, the milk is pumped into the pre-cooling tank/refrigerating tank through the milk pump. The pre-cooling tank and the refrigerating tank are the same tanks, and the two processes are completed by different temperatures and cooling medium. The pre-cooling process uses cold water to pre-cool down. The cooling time is about 0.3-0.5 hours. Generally, the temperature can be lowered to below 45 °C to enter the freon-cooled compressor refrigeration tank. Otherwise, the quality of the milk and the service life of the equipment will be affected.

When the cooling is completed, the refrigerating tank has the function of fermentation at the same time. After adding the probiotics, the temperature was controlled at about 42 degrees Celsius, and the fermentation was carried out for 8 hours.

Parameters of the pre-cooling / fermentation machine

| 300L preheating / sterilization / fermentation parameters | |

| Size(mm) | 1200*1000*1650 |

| Tank diameter | 800mm |

| Tank height | 600mm |

| Material | 304 stainless steel |

| thickness | 2mm |

| Mixer speed | 36r/min |

| Heating area | 1.6 |

| Mixer motor power | 0.55kw |

| Logistics import and export | DN40 |

| Voltage | 380V/50hz |

| Power | 18kw |

Step 7: Filling and packaging (filling and packaging machine)

In the yogurt production line, the packaging machine integrates automatic drop cup, automatic filling, automatic film release, automatic sealing, automatic cupping, and other processes. Made of high quality 304 stainless steel, the corners of the machine are passivated to prevent cuts. Sealing heating plate, using a high-quality core heating plate, evenly heated, high-temperature resistance, no deformation, can ensure the beauty of the finished product. 1000 cups can be filled in one hour. This machine is suitable for the packaging of any viscous material.

Filling and packaging machine parameters

| Paper cup disc filling machine | |

| Size (mm) | 1300*1300*1750 |

| ration | 50-300ml |

| Capacity | 800-1000cup/h |

| Material | 304 stainless steel |

| Disc speed | 13-16 per min |

| Weight | About 200kg |

Why choose this yogurt production line?

- The whole yogurt production line is made of high quality 304 stainless steel, which is resistant to high temperature, corrosion, and deformation, and meets the safety and hygiene standards of food machines.

- Microcomputer control, simple and intelligent operation. Circuit protection components prevent overvoltage and overcurrent damage to the machine.

- Temperature and time can be set. After reaching the set time, it can automatically alarm, saving effort.

- Support customization, each machine on this production line supports customization.

- The warranty period is one year. During this period, the company will be fully responsible for the problems arising from the quality of the products. If the users fail to follow the operating procedures or intentionally cause damage to the equipment, the company will also provide telephone guidance to help the users solve the problems, but the users will bear the cost of replacing the parts accordingly.

- If necessary, our company can send professional technicians to the local area to guide the installation.

The FAQ of the yogurt production line

- Does this line produce liquid yogurt or solid yogurt?

A: Solid yogurt. Liquid yogurt needs to be equipped with the relevant machine.

- What is the production capacity?

A: Each machine has a milk storage capacity of 300L (500L). Fermentation takes 8 hours, and it can be equipped with several fermenters and cycle work.

- Must I use this filling machine?

A: We also have other styles of packaging machines for you to choose from.

- What is the temperature range of the refrigerating tank?

A:4-45 degrees Celsius, 45 degrees or more does not work.

- What is the ratio of materials that can be added during the making of yogurt?

A: The ratio of bacteria, milk, and white sugar is 1 liter of milk plus 6-8% sugar, 1 g of bacteria.

- What is the working principle of the sterilization barrel?

A: Pasteurization.

Successful case

The yogurt production line is a relatively mature production line of our company and has been successfully sold to many countries. A month ago, customers from Nigeria purchased a yogurt production line from our company. It is currently in use and is beginning to make a profit.